design for manufacturing sheet metal Learn how to effectively design sheet metal parts. This guide starts with the basics and moves toward design best practices and advice on material selection, finishings and fastenings, with a focus on two sheet metal fabrication processes: bending and laser cutting. Metal fabrication consists of processes used to produce products, components and structures from raw metals. Item or items created by these processes are often known as fabrications. Manufacturing companies perform metal fabrication using a combination of manual and automated processes.

0 · sheet metal stamping process pdf

1 · sheet metal practice drawings pdf

2 · sheet metal material list pdf

3 · sheet metal layout pdf

4 · sheet metal fabrication handbook pdf

5 · sheet metal design guidelines pdf

6 · sheet metal design calculations pdf

7 · sheet metal calculations pdf

A Septic Tank Distribution Box, also known as a D-box, is a junction box positioned between the septic tank and the drain field (or leach field). Its primary function is to evenly distribute the effluent (wastewater) from the septic tank into the various distribution lines within the drain field.

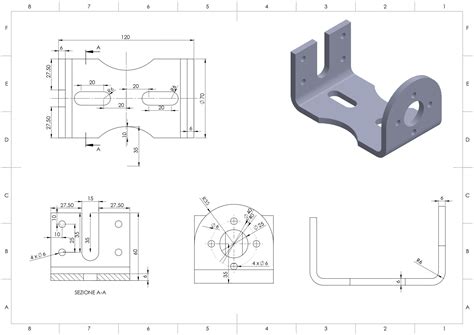

Learn how to effectively design sheet metal parts. This guide starts with the basics and moves toward design best practices and advice on material selection, finishings and fastenings, with . In this article, we will provide a comprehensive guide to sheet metal fabrication design, including tips for material selection, geometric constraints, and cost-effective design strategies.

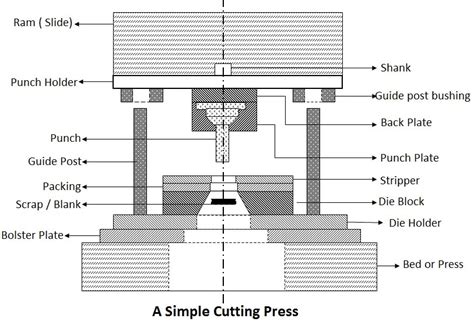

Sheet metal fabrication is a complex manufacturing process that includes cutting, bending, hole punching, embossing, and many other forming operations. As the parts have more features, the complexity of the design also increases. Therefore, you must consider the sheet metal design guidelines to ensure manufacturability.Learn how to effectively design sheet metal parts. This guide starts with the basics and moves toward design best practices and advice on material selection, finishings and fastenings, with a focus on two sheet metal fabrication processes: bending and laser cutting. In this article, we will provide a comprehensive guide to sheet metal fabrication design, including tips for material selection, geometric constraints, and cost-effective design strategies.

Sheet metal fabrication is a comprehensive cold-working process for thin metal sheets, typically less than 6 mm in thickness. This versatile manufacturing method encompasses a wide range of operations, including shearing, blanking, bending, welding, riveting, die forming, and surface treatments.Geomiq's Sheet Metal design guide helps you with your design process to accelerate production time and reduce production costs. Geomiq’s digital manufacturing platform makes rapid prototype and production manufacturing easy.

Sheet metal fabrication is a highly versatile process used in the manufacturing industry to create various parts and components. This process involves cutting, forming, and assembling metal into different shapes and structures. The first step in creating a sheet metal part is sheet metal design.

Sheet metal design guidelines are followed for sheet metal enclosure and part design to ensure the first time right product and reduce cost.Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a machine to precisely cut a flat pattern, which can be formed .The sheet metal design process involves conceptualizing, drawing, and creating detailed plans for cutting, shaping, and joining metal. It’s all about turning metal sheets into durable, functional, and aesthetic products for various industries, from aerospace to .

Prioritize material selection and geometric considerations for efficient sheet metal fabrication. Embrace DFM principles to minimize costs and enhance product quality in manufacturing. Implement design guidelines and tolerance specifications tailored for .

Sheet metal fabrication is a complex manufacturing process that includes cutting, bending, hole punching, embossing, and many other forming operations. As the parts have more features, the complexity of the design also increases. Therefore, you must consider the sheet metal design guidelines to ensure manufacturability.Learn how to effectively design sheet metal parts. This guide starts with the basics and moves toward design best practices and advice on material selection, finishings and fastenings, with a focus on two sheet metal fabrication processes: bending and laser cutting. In this article, we will provide a comprehensive guide to sheet metal fabrication design, including tips for material selection, geometric constraints, and cost-effective design strategies. Sheet metal fabrication is a comprehensive cold-working process for thin metal sheets, typically less than 6 mm in thickness. This versatile manufacturing method encompasses a wide range of operations, including shearing, blanking, bending, welding, riveting, die forming, and surface treatments.

Geomiq's Sheet Metal design guide helps you with your design process to accelerate production time and reduce production costs. Geomiq’s digital manufacturing platform makes rapid prototype and production manufacturing easy.

Sheet metal fabrication is a highly versatile process used in the manufacturing industry to create various parts and components. This process involves cutting, forming, and assembling metal into different shapes and structures. The first step in creating a sheet metal part is sheet metal design.Sheet metal design guidelines are followed for sheet metal enclosure and part design to ensure the first time right product and reduce cost.Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a machine to precisely cut a flat pattern, which can be formed .

The sheet metal design process involves conceptualizing, drawing, and creating detailed plans for cutting, shaping, and joining metal. It’s all about turning metal sheets into durable, functional, and aesthetic products for various industries, from aerospace to .

sheet metal stamping process pdf

b&g junction box wiring autopilot

bad junction box car

When a fixture has a fill allocation, you can add the junction box allocation to the fixture allocation in order to calculate overall box fill. Direct wire fixtures already have the required allocation, so .

design for manufacturing sheet metal|sheet metal layout pdf