cnc machine setup In this blog post, we will walk you through the basics of machine setup, explain essential terminology like G-code and toolpaths, and provide additional CNC terms to enhance your . HARDO manufactures customized explosion-proof junction boxes for zones 0, 1, 2 (for gases and vapors) and 21, 22 (for dust). You have full control over the selection of the type, size and mounting location of glands and cable terminals.

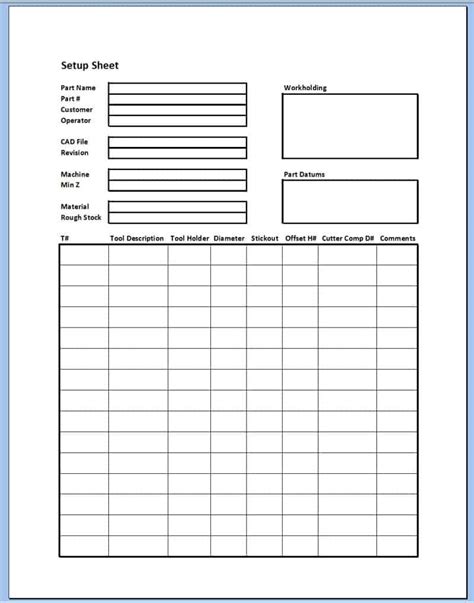

0 · cnc tool set up sheet

1 · cnc machines for dummies

2 · cnc machine setup sheet template

3 · cnc machine setup checklist

4 · cnc machine set up sheet

5 · cnc machine process step by

6 · cnc machine operating instructions

7 · cnc lathe setup sheet

ZVex Box of Metal Another one to keep you busy for a while. This version is the effect only and no gate so you'll have to use an ISP Decimator or something with it if it's noisy :o)

CNC milling machines are used in a variety of industries, from automotive to aerospace, and are prized for their accuracy and efficiency. In this article, we will provide a step-by-step guide on how to set up a CNC milling . Discover the essentials of CNC machine setup in our 2024 guide. Learn setup steps, safety protocols, and maintenance for optimal CNC performance.

miscellaneous metal fabricators somerset wi

Follow these steps to set up your SYIL CNC machine for operation: Ensure the machine is placed on a stable and level surface. Connect the machine to a power source and ensure it is properly grounded. In this video, I'll cover all the CNC basics that you must know before being able to run the machine. This includes CAD, CAM, Feeds and Speeds, Toolpaths, G-code, and .In this blog post, we will walk you through the basics of machine setup, explain essential terminology like G-code and toolpaths, and provide additional CNC terms to enhance your .

This video series is on machine setup and alignment. We will walk through all the steps needed to get your machi.

miscellaneous metal fabrication

The setup process includes initializing and resetting the machine, selecting and setting up tools, installing and positioning the workpiece, importing and verifying the machining .Before machining begins, the CNC machine must be set up with the appropriate tools and materials. This setup is crucial for ensuring accuracy and efficiency. Machine Preparation: Install the appropriate cutting tools and secure the .After assembling your CNC machine, the instructions below will guide you through additional setup steps. Some items may not be applicable, depending on how your machine is .Now come to the setting up machine, although every CNC Milling machine set-up procedure is slightly different, but here are explained these generic steps which cnc machinists practice on a daily basis for a 3 axis vertical CNC Milling machine.

mk junction box screwfix

CNC milling machines are used in a variety of industries, from automotive to aerospace, and are prized for their accuracy and efficiency. In this article, we will provide a step-by-step guide on how to set up a CNC milling machine, covering everything from initial inspection to .

Discover the essentials of CNC machine setup in our 2024 guide. Learn setup steps, safety protocols, and maintenance for optimal CNC performance.Follow these steps to set up your SYIL CNC machine for operation: Ensure the machine is placed on a stable and level surface. Connect the machine to a power source and ensure it is properly grounded. In this video, I'll cover all the CNC basics that you must know before being able to run the machine. This includes CAD, CAM, Feeds and Speeds, Toolpaths, G-code, and setting up the machine.In this blog post, we will walk you through the basics of machine setup, explain essential terminology like G-code and toolpaths, and provide additional CNC terms to enhance your understanding of this fascinating field.

This video series is on machine setup and alignment. We will walk through all the steps needed to get your machi.

The setup process includes initializing and resetting the machine, selecting and setting up tools, installing and positioning the workpiece, importing and verifying the machining program, and checking machine safety features.

Before machining begins, the CNC machine must be set up with the appropriate tools and materials. This setup is crucial for ensuring accuracy and efficiency. Machine Preparation: Install the appropriate cutting tools and secure the material blank. Tool Calibration: Calibrate tools to ensure correct positioning and alignment.After assembling your CNC machine, the instructions below will guide you through additional setup steps. Some items may not be applicable, depending on how your machine is configured. Guides for installation, setup, and usage of Centroid CNC12 CNC controller software and compatible accessories.

cnc tool set up sheet

cnc machines for dummies

Now come to the setting up machine, although every CNC Milling machine set-up procedure is slightly different, but here are explained these generic steps which cnc machinists practice on a daily basis for a 3 axis vertical CNC Milling machine. CNC milling machines are used in a variety of industries, from automotive to aerospace, and are prized for their accuracy and efficiency. In this article, we will provide a step-by-step guide on how to set up a CNC milling machine, covering everything from initial inspection to .

Discover the essentials of CNC machine setup in our 2024 guide. Learn setup steps, safety protocols, and maintenance for optimal CNC performance.

cnc machine setup sheet template

Follow these steps to set up your SYIL CNC machine for operation: Ensure the machine is placed on a stable and level surface. Connect the machine to a power source and ensure it is properly grounded. In this video, I'll cover all the CNC basics that you must know before being able to run the machine. This includes CAD, CAM, Feeds and Speeds, Toolpaths, G-code, and setting up the machine.In this blog post, we will walk you through the basics of machine setup, explain essential terminology like G-code and toolpaths, and provide additional CNC terms to enhance your understanding of this fascinating field.

This video series is on machine setup and alignment. We will walk through all the steps needed to get your machi.

The setup process includes initializing and resetting the machine, selecting and setting up tools, installing and positioning the workpiece, importing and verifying the machining program, and checking machine safety features.Before machining begins, the CNC machine must be set up with the appropriate tools and materials. This setup is crucial for ensuring accuracy and efficiency. Machine Preparation: Install the appropriate cutting tools and secure the material blank. Tool Calibration: Calibrate tools to ensure correct positioning and alignment.

After assembling your CNC machine, the instructions below will guide you through additional setup steps. Some items may not be applicable, depending on how your machine is configured. Guides for installation, setup, and usage of Centroid CNC12 CNC controller software and compatible accessories.

misc metal fabricators near me

mk white 30a 3 way junction box 86mm

The Box of Metal (tm) is an aggressive high-gain pedal with a highly-effective built-in switchable gate which dramatically reduces noise and unwanted feedback. Its gain and tonal characteristics are somewhat similar to high-gain tube amplifiers that have been the staple of hard rock and metal sounds since the 80's.

cnc machine setup|cnc lathe setup sheet