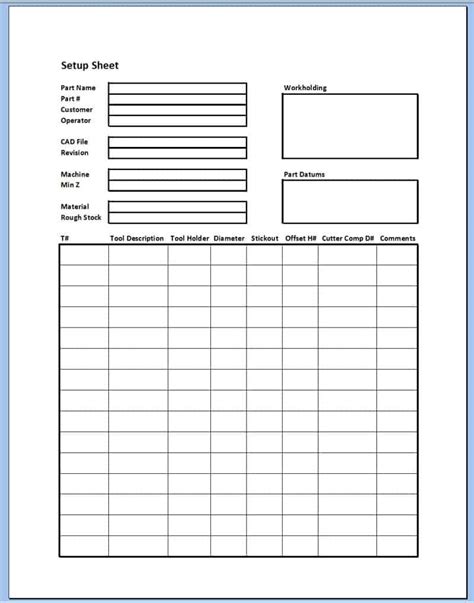

cnc machine setup tools Learn how to create a setup sheet for your CNC machines with our step-by-step guide. Improve your workflow and productivity today! Type C conduit bodies connect two conduits in a straight line. There are openings at the top and bottom for conduits to connect with the body. While Type C conduit bodies do not alter the direction that the wires travel, they feature removable .

0 · cnc tool set up sheet

1 · cnc machines for dummies

2 · cnc machine setup sheet template

3 · cnc machine setup checklist

4 · cnc machine set up sheet

5 · cnc machine process step by

6 · cnc machine operating instructions

7 · cnc lathe setup sheet

1594 Fortis 3 Phase 832 Junction Vault Product # Steel Lid & Concrete Collar - H20 Dynamic 1127 Fortis # 755-0560 INSTALLATION INFORMATION DESIGNED FOR H-20 DYNAMIC LOADING 4 - 2.5T DOGBONE STYLE LIFTING ANCHORS WEIGHT: LBS / KG

Setting up a CNC milling machine can seem daunting at first, but with the right knowledge and tools, it can be a smooth process. By following the steps outlined in this article, users can ensure their machine is properly . Learn how to create a setup sheet for your CNC machines with our step-by-step guide. Improve your workflow and productivity today!

We at CAMaster prepared this guide to help you with CNC machine setup. Created for beginners and experienced professionals alike, it provides clear, step-by-step instructions. .CNC, or Computer Numerical Control, machining refers to the process of using computers to control machine tools. This technology allows for greater precision, complexity, and efficiency .Before machining begins, the CNC machine must be set up with the appropriate tools and materials. This setup is crucial for ensuring accuracy and efficiency. Machine Preparation: Install the appropriate cutting tools and secure the .Choosing the right tools for your CNC machine setup is vital for achieving accurate and efficient machining results. This section will delve into the selection criteria for various types of cutting .

cnc tool set up sheet

In this article, we will provide you with an in-depth checklist to ensure a smooth and efficient setup process for your CNC machine. Whether you're a beginner or an experienced operator, .

lowes electrical junction box

How to Set Up CNC Milling Machine - Although every CNC Milling machine set-up is slightly different, but here are explained these generic steps which cnc machinists practice on a daily basis for a 3 axis vertical CNC Milling machine. In this comprehensive guide, we will explore the essential CNC machining tools that every machinist needs to have. From cutting tools to measuring tools, workholding devices, coolants and lubricants, safety .

Setting up a CNC milling machine can seem daunting at first, but with the right knowledge and tools, it can be a smooth process. By following the steps outlined in this article, users can ensure their machine is properly calibrated and ready for use.Learn how to create a setup sheet for your CNC machines with our step-by-step guide. Improve your workflow and productivity today! Know about the basic tools for machinists and choose the best one or create your customized toolbox that suits your needs. Here we put the recommended must have machinist tools for CNC machine shop or manual work. 1. Calipers.

We at CAMaster prepared this guide to help you with CNC machine setup. Created for beginners and experienced professionals alike, it provides clear, step-by-step instructions. Whether setting up a home CNC machine or preparing for large-scale production, this guide is your gateway to becoming a skilled CNC machine operator. Understanding CNC .CNC, or Computer Numerical Control, machining refers to the process of using computers to control machine tools. This technology allows for greater precision, complexity, and efficiency in manufacturing compared to traditional methods. CNC machines can be used to cut, grind, mill, and carve materials like wood, metal, and plastic.Before machining begins, the CNC machine must be set up with the appropriate tools and materials. This setup is crucial for ensuring accuracy and efficiency. Machine Preparation: Install the appropriate cutting tools and secure the material blank. Tool Calibration: Calibrate tools to ensure correct positioning and alignment.Choosing the right tools for your CNC machine setup is vital for achieving accurate and efficient machining results. This section will delve into the selection criteria for various types of cutting tools, such as end mills, drills, and boring bars.

In this article, we will provide you with an in-depth checklist to ensure a smooth and efficient setup process for your CNC machine. Whether you're a beginner or an experienced operator, following this checklist will help you achieve optimal performance and precision.How to Set Up CNC Milling Machine - Although every CNC Milling machine set-up is slightly different, but here are explained these generic steps which cnc machinists practice on a daily basis for a 3 axis vertical CNC Milling machine. In this comprehensive guide, we will explore the essential CNC machining tools that every machinist needs to have. From cutting tools to measuring tools, workholding devices, coolants and lubricants, safety equipment, and software tools, we’ll cover everything you need to know to set up a successful CNC machining operation.

Setting up a CNC milling machine can seem daunting at first, but with the right knowledge and tools, it can be a smooth process. By following the steps outlined in this article, users can ensure their machine is properly calibrated and ready for use.Learn how to create a setup sheet for your CNC machines with our step-by-step guide. Improve your workflow and productivity today!

Know about the basic tools for machinists and choose the best one or create your customized toolbox that suits your needs. Here we put the recommended must have machinist tools for CNC machine shop or manual work. 1. Calipers. We at CAMaster prepared this guide to help you with CNC machine setup. Created for beginners and experienced professionals alike, it provides clear, step-by-step instructions. Whether setting up a home CNC machine or preparing for large-scale production, this guide is your gateway to becoming a skilled CNC machine operator. Understanding CNC .CNC, or Computer Numerical Control, machining refers to the process of using computers to control machine tools. This technology allows for greater precision, complexity, and efficiency in manufacturing compared to traditional methods. CNC machines can be used to cut, grind, mill, and carve materials like wood, metal, and plastic.Before machining begins, the CNC machine must be set up with the appropriate tools and materials. This setup is crucial for ensuring accuracy and efficiency. Machine Preparation: Install the appropriate cutting tools and secure the material blank. Tool Calibration: Calibrate tools to ensure correct positioning and alignment.

Choosing the right tools for your CNC machine setup is vital for achieving accurate and efficient machining results. This section will delve into the selection criteria for various types of cutting tools, such as end mills, drills, and boring bars.In this article, we will provide you with an in-depth checklist to ensure a smooth and efficient setup process for your CNC machine. Whether you're a beginner or an experienced operator, following this checklist will help you achieve optimal performance and precision.

How to Set Up CNC Milling Machine - Although every CNC Milling machine set-up is slightly different, but here are explained these generic steps which cnc machinists practice on a daily basis for a 3 axis vertical CNC Milling machine.

7 talking about this

cnc machine setup tools|cnc machine set up sheet