electric vehicle battery box assembly adhesives Assembling electric vehicle (EV) battery boxes using structural adhesives instead of mechanical fasteners not only results in process efficiencies but can help installed boxes perform better. Here are five ways how. $9.99

0 · electric vehicle battery design

1 · adhesive for electric vehicles

There is a flat wide connector plugging into the BACKSIDE of this same junction box. There are about a dozen small wires going into it and one big brown ground. This is the one you need to get to.

Different adhesives are used in EV battery box assembly, each offering unique properties suited to various requirements. The selection of the appropriate adhesive depends .Assembling electric vehicle (EV) battery boxes using structural adhesives instead of mechanical fasteners not only results in process efficiencies but can help installed boxes perform better. Here are five ways how. Adhesives, sealants, gaskets, and thermal materials play an essential role in several areas of the EV battery’s technology, including the .Most importantly structural Master Bond one and two component adhesive systems can be used to attach battery cells, modules, and packs. Specialty systems are engineered to provide .

AR’s portfolio of pressure sensitive adhesives is designed for a broad range of applications throughout the cell, module, and pack, including electrode and conductive bonding, .Fix fast & Bond durable: based on fast-fixing cyanoacrylates, in combination with structural adhesives like methyl methacrylate (MMA) or polyurethane (PU) technologies, these adhesives provide a complete and innovative solution to .

Learn about the role die-cut adhesives play in EV battery applications in this JBC Technologies post featuring a Q&A with Avery Dennison Performance Tapes. Adhesive technology plays a vital role in the assembly and performance of electric vehicle battery packs. From ensuring structural integrity to managing heat and enhancing safety, adhesives, and sealants contribute .

electric vehicle battery design

No traditional structural adhesive offers performance, processing and sustainability demands needed to meet EV battery box requirements.Battery assembly adhesives enable cost-efficient and fast assembly of prismatic, cylindrical or pouch cells. Dielectric Coatings. Different adhesives are used in EV battery box assembly, each offering unique properties suited to various requirements. The selection of the appropriate adhesive depends on factors such as bonding surfaces, environmental conditions, and thermal management needs.

Assembling electric vehicle (EV) battery boxes using structural adhesives instead of mechanical fasteners not only results in process efficiencies but can help installed boxes perform better. Here are five ways how.

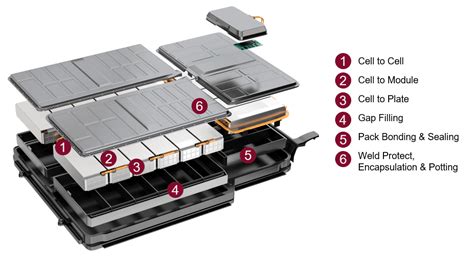

Adhesives, sealants, gaskets, and thermal materials play an essential role in several areas of the EV battery’s technology, including the battery cells, battery modules, battery packs, and the battery management system (BMS). The battery cell is .Most importantly structural Master Bond one and two component adhesive systems can be used to attach battery cells, modules, and packs. Specialty systems are engineered to provide remarkable thermally conductive characteristics to satisfy arduous cooling requirements.AR’s portfolio of pressure sensitive adhesives is designed for a broad range of applications throughout the cell, module, and pack, including electrode and conductive bonding, encapsulation, device wrapping, shock absorbency, and process aids.Fix fast & Bond durable: based on fast-fixing cyanoacrylates, in combination with structural adhesives like methyl methacrylate (MMA) or polyurethane (PU) technologies, these adhesives provide a complete and innovative solution to ensuring proper, durable EV .

Learn about the role die-cut adhesives play in EV battery applications in this JBC Technologies post featuring a Q&A with Avery Dennison Performance Tapes. Adhesive technology plays a vital role in the assembly and performance of electric vehicle battery packs. From ensuring structural integrity to managing heat and enhancing safety, adhesives, and sealants contribute significantly to the success of EVs.No traditional structural adhesive offers performance, processing and sustainability demands needed to meet EV battery box requirements.

Battery assembly adhesives enable cost-efficient and fast assembly of prismatic, cylindrical or pouch cells. Dielectric Coatings. Different adhesives are used in EV battery box assembly, each offering unique properties suited to various requirements. The selection of the appropriate adhesive depends on factors such as bonding surfaces, environmental conditions, and thermal management needs.Assembling electric vehicle (EV) battery boxes using structural adhesives instead of mechanical fasteners not only results in process efficiencies but can help installed boxes perform better. Here are five ways how.

Adhesives, sealants, gaskets, and thermal materials play an essential role in several areas of the EV battery’s technology, including the battery cells, battery modules, battery packs, and the battery management system (BMS). The battery cell is .

Most importantly structural Master Bond one and two component adhesive systems can be used to attach battery cells, modules, and packs. Specialty systems are engineered to provide remarkable thermally conductive characteristics to satisfy arduous cooling requirements.

AR’s portfolio of pressure sensitive adhesives is designed for a broad range of applications throughout the cell, module, and pack, including electrode and conductive bonding, encapsulation, device wrapping, shock absorbency, and process aids.Fix fast & Bond durable: based on fast-fixing cyanoacrylates, in combination with structural adhesives like methyl methacrylate (MMA) or polyurethane (PU) technologies, these adhesives provide a complete and innovative solution to ensuring proper, durable EV . Learn about the role die-cut adhesives play in EV battery applications in this JBC Technologies post featuring a Q&A with Avery Dennison Performance Tapes.

Adhesive technology plays a vital role in the assembly and performance of electric vehicle battery packs. From ensuring structural integrity to managing heat and enhancing safety, adhesives, and sealants contribute significantly to the success of EVs.No traditional structural adhesive offers performance, processing and sustainability demands needed to meet EV battery box requirements.

adhesive for electric vehicles

the junction box model

KSM Metal Fabrication will work with your facilities people to correctly install your .

electric vehicle battery box assembly adhesives|electric vehicle battery design