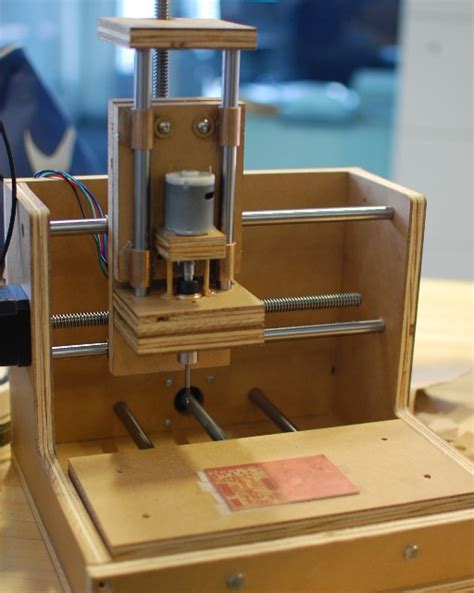

build a wood cnc machine I know a lot of CNC dreamers do not have the knowledge or tools to build a full metal machine. I still think and hope this Instructable inspires you to make your own machine. I include all of the necessary steps I went through in designing .

Electrical boxes, or junction boxes, are crucial components in electrical installations. Understanding the different types of electrical boxes and their specific uses is essential for anyone involved in electrical work or home improvement projects.

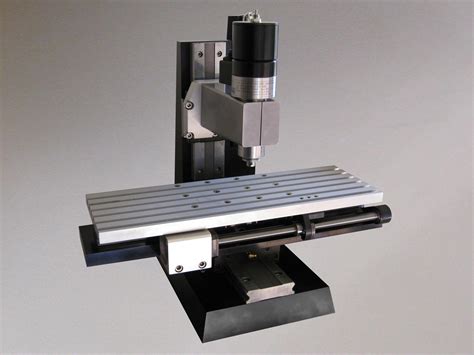

0 · make your own cnc mill

1 · make your own cnc machine

2 · do it yourself cnc machine

3 · diy woodworking cnc

4 · diy cnc machine for woodworking

5 · building your own cnc router

6 · building your own cnc machine

7 · build your own cnc mill

Whether you need PVC Couplings or PVC Junction Boxes, you can always contact CANTEX directly to inquire about any of our PVC fittings. What Type .

Turn your woodworking shop into a machining, cutting, carving, and milling powerhouse with our shop-made, CNC machine. __Get the step .Building your own 3-Axis CNC router is both fun and educational. These plans document all the steps I followed to make my DIY CNC Router. This is the second DIY CNC Router I made, . A DIY CNC router may sound like a fun project, but it can be a challenge even for discerning makers. Here's what you need to know.Most homemade CNC routers use a standard woodworking router or trim router as the cutting spindle for their machine. Mine is no exception. I used a Kress .

To build a woodworking CNC machine, you will need a variety of tools and materials. This comprehensive list includes both essential components that are necessary for the basic .I know a lot of CNC dreamers do not have the knowledge or tools to build a full metal machine. I still think and hope this Instructable inspires you to make your own machine. I include all of the necessary steps I went through in designing .

Homemade 2'x4' Wood CNC Router: Here I am going to show how I made my CNC (Computer Numerical Controlled) router. The table measures 24"x48" and the cutting envelope is about 19”x38.” I made this CNC when I was 17 years .A DIY CNC router (Computer Numerical Control) is a versatile tool that allows hobbyists, makers, and small businesses to build precise cuts, engravings, and 3D carvings. Unlike traditional handheld routers, CNC routers are automated .Baltic birch plywood, some basic hardware, and an off-the-shelf electronics kit are all you need to build your own computer-controlled router. This project is ideal for tech-savvy woodworkers looking to add a CNC router to their shop or .Here are a few steps that will help you build your own CNC router and allow you to work on intricate woodworking projects: What specifications are you looking at? If the market for CNC machines are full of a wide range in size, you can .

Turn your woodworking shop into a machining, cutting, carving, and milling powerhouse with our shop-made, CNC machine. __Get the step-by-step plans for this Shop-Built CNC Router at WoodsmithPlans.com. __Building your own 3-Axis CNC router is both fun and educational. These plans document all the steps I followed to make my DIY CNC Router. This is the second DIY CNC Router I made, after learning a lot from building the first version. This is a very good router that can be built at a reasonable price using readily available materials. This A DIY CNC router may sound like a fun project, but it can be a challenge even for discerning makers. Here's what you need to know.Most homemade CNC routers use a standard woodworking router or trim router as the cutting spindle for their machine. Mine is no exception. I used a Kress router, which is of slightly higher quality than standard wood routers, and it has a nice 43mm clamping flange.

To build a woodworking CNC machine, you will need a variety of tools and materials. This comprehensive list includes both essential components that are necessary for the basic functioning of the machine, as well as optional components that can enhance its capabilities.

make your own cnc mill

make your own cnc machine

I know a lot of CNC dreamers do not have the knowledge or tools to build a full metal machine. I still think and hope this Instructable inspires you to make your own machine. I include all of the necessary steps I went through in designing and building this CNC milling machine.Homemade 2'x4' Wood CNC Router: Here I am going to show how I made my CNC (Computer Numerical Controlled) router. The table measures 24"x48" and the cutting envelope is about 19”x38.” I made this CNC when I was 17 years old and .

A DIY CNC router (Computer Numerical Control) is a versatile tool that allows hobbyists, makers, and small businesses to build precise cuts, engravings, and 3D carvings. Unlike traditional handheld routers, CNC routers are automated and follow digital designs.

Baltic birch plywood, some basic hardware, and an off-the-shelf electronics kit are all you need to build your own computer-controlled router. This project is ideal for tech-savvy woodworkers looking to add a CNC router to their shop or beginners who want to give this type of woodworking technology a try.Here are a few steps that will help you build your own CNC router and allow you to work on intricate woodworking projects: What specifications are you looking at? If the market for CNC machines are full of a wide range in size, you can choose to . Turn your woodworking shop into a machining, cutting, carving, and milling powerhouse with our shop-made, CNC machine. __Get the step-by-step plans for this Shop-Built CNC Router at WoodsmithPlans.com. __

Building your own 3-Axis CNC router is both fun and educational. These plans document all the steps I followed to make my DIY CNC Router. This is the second DIY CNC Router I made, after learning a lot from building the first version. This is a very good router that can be built at a reasonable price using readily available materials. This A DIY CNC router may sound like a fun project, but it can be a challenge even for discerning makers. Here's what you need to know.Most homemade CNC routers use a standard woodworking router or trim router as the cutting spindle for their machine. Mine is no exception. I used a Kress router, which is of slightly higher quality than standard wood routers, and it has a nice 43mm clamping flange.

To build a woodworking CNC machine, you will need a variety of tools and materials. This comprehensive list includes both essential components that are necessary for the basic functioning of the machine, as well as optional components that can enhance its capabilities.I know a lot of CNC dreamers do not have the knowledge or tools to build a full metal machine. I still think and hope this Instructable inspires you to make your own machine. I include all of the necessary steps I went through in designing and building this CNC milling machine.Homemade 2'x4' Wood CNC Router: Here I am going to show how I made my CNC (Computer Numerical Controlled) router. The table measures 24"x48" and the cutting envelope is about 19”x38.” I made this CNC when I was 17 years old and .

A DIY CNC router (Computer Numerical Control) is a versatile tool that allows hobbyists, makers, and small businesses to build precise cuts, engravings, and 3D carvings. Unlike traditional handheld routers, CNC routers are automated and follow digital designs.Baltic birch plywood, some basic hardware, and an off-the-shelf electronics kit are all you need to build your own computer-controlled router. This project is ideal for tech-savvy woodworkers looking to add a CNC router to their shop or beginners who want to give this type of woodworking technology a try.

do it yourself cnc machine

electricity meter box location requirements qld

Types of Metal Brackets. Bracket variations differ depending on the uses and the things they are meant to support. L-brackets, Box brackets, J-brackets, U-brackets, gusset brackets, and Z .

build a wood cnc machine|do it yourself cnc machine