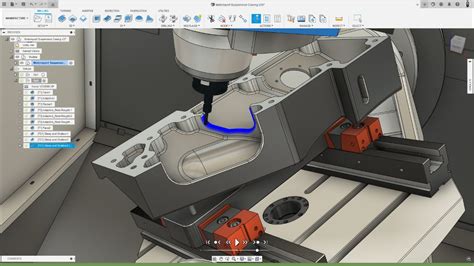

autocad to cnc machine CNC software from Autodesk integrates CAD and CAE capabilities with its CAM functions, making manufacturing smoother overall. CNC machines can also run efficiently all day, every day, with the flexibility to make quick changes straight .

West Metal Fabricators Ltd is a reputable company based in London, ON, specializing in metal fabrication services. With a focus on precision and quality, they cater to a diverse range of industries, providing custom solutions to meet their clients' needs.

0 · fusion 360 for cnc mill

1 · create cnc file from drawing

2 · cnc milling machine programming software

3 · cad software for cnc machine

4 · cad drawing for cnc machine

5 · autodesk cnc programming software

6 · auto cad drawing cnc

7 · AutoCAD cnc programming

How to Weld Auto Body Sheet Metal With a TIG Welder. The best two electrodes for welding auto body sheet metal are either ceriated tungsten or thoriated tungsten.

Combining CNC software with CNC machines makes the same precision and accuracy of 3D CAD models physically possible. Some CNC software, such as Autodesk Fusion, also includes simulation abilities that test the machining process virtually to identify potential errors and .

Autodesk Fusion for Manufacturing is a more capable version of Fusion that .We have a solution to analyze the solids - recognizing all the holes, part sizes, .Connect disciplines using common CAD models to program CNC machines. .Autodesk Fusion for Manufacturing is a more capable version of Fusion that provides additional, advanced CAM capabilities for CNC machining (milling and turning), sheet-based nesting and fabrication, and 3D printing in a range of .

CNC software from Autodesk integrates CAD and CAE capabilities with its CAM functions, making manufacturing smoother overall. CNC machines can also run efficiently all day, every day, with the flexibility to make quick changes straight .

fusion 360 for cnc mill

create cnc file from drawing

Modern CNC machining systems can interpret the part geometry directly from the 3D CAD file with the onboard computer or receive the G-code output of the CAM software. how to convert autocad drawing to cnc program Assuming that you have already optimized your design for CNC production, the steps you should follow are: Export your design in a CNC-compatible format; Prepare a technical drawing; Get a quote from an online . Therefore, this article is dedicated to helping you learn how to prepare CAD files for CNC machining. 1. Optimize Tolerances. 2. Type of Material. 3. Minimize the Number of Machined Features. 4. Minimize .

We have a solution to analyze the solids - recognizing all the holes, part sizes, applying the tool pathing, creating the CNC machine code through our post processors, etc. We connect to (create the g-code) virtually . AutoCAD does not have built-in CAM functionality and, as such, its use for CNC is limited. However, AutoCAD is often used to develop 2D profiles for laser cutting, and most laser cutting facilities accept the Autocad DXF format.Connect disciplines using common CAD models to program CNC machines. Design fixtures and create toolpaths before engineering data is released—any changes automatically update computer-aided manufacturing (CAM) workflows.

Combining CNC software with CNC machines makes the same precision and accuracy of 3D CAD models physically possible. Some CNC software, such as Autodesk Fusion, also includes simulation abilities that test the machining process virtually .Autodesk Fusion for Manufacturing is a more capable version of Fusion that provides additional, advanced CAM capabilities for CNC machining (milling and turning), sheet-based nesting and fabrication, and 3D printing in a range of materials.

cnc milling machine programming software

CNC software from Autodesk integrates CAD and CAE capabilities with its CAM functions, making manufacturing smoother overall. CNC machines can also run efficiently all day, every day, with the flexibility to make quick changes straight from the CNC software. Modern CNC machining systems can interpret the part geometry directly from the 3D CAD file with the onboard computer or receive the G-code output of the CAM software.

how to convert autocad drawing to cnc program Assuming that you have already optimized your design for CNC production, the steps you should follow are: Export your design in a CNC-compatible format; Prepare a technical drawing; Get a quote from an online service. Let’s study each of these three steps in further detail to examine the best practices. Therefore, this article is dedicated to helping you learn how to prepare CAD files for CNC machining. 1. Optimize Tolerances. 2. Type of Material. 3. Minimize the Number of Machined Features. 4. Minimize Machined Stock Allowance. 5. Standardize Features. 6. Surface Finish. 7. Provide Adequate Strength and Stiffness. 8. We have a solution to analyze the solids - recognizing all the holes, part sizes, applying the tool pathing, creating the CNC machine code through our post processors, etc. We connect to (create the g-code) virtually any 3-axis CNC for flat panel processing and optimization.

red deer metal fabrication

AutoCAD does not have built-in CAM functionality and, as such, its use for CNC is limited. However, AutoCAD is often used to develop 2D profiles for laser cutting, and most laser cutting facilities accept the Autocad DXF format.Connect disciplines using common CAD models to program CNC machines. Design fixtures and create toolpaths before engineering data is released—any changes automatically update computer-aided manufacturing (CAM) workflows.Combining CNC software with CNC machines makes the same precision and accuracy of 3D CAD models physically possible. Some CNC software, such as Autodesk Fusion, also includes simulation abilities that test the machining process virtually .Autodesk Fusion for Manufacturing is a more capable version of Fusion that provides additional, advanced CAM capabilities for CNC machining (milling and turning), sheet-based nesting and fabrication, and 3D printing in a range of materials.

CNC software from Autodesk integrates CAD and CAE capabilities with its CAM functions, making manufacturing smoother overall. CNC machines can also run efficiently all day, every day, with the flexibility to make quick changes straight from the CNC software. Modern CNC machining systems can interpret the part geometry directly from the 3D CAD file with the onboard computer or receive the G-code output of the CAM software. how to convert autocad drawing to cnc program

Assuming that you have already optimized your design for CNC production, the steps you should follow are: Export your design in a CNC-compatible format; Prepare a technical drawing; Get a quote from an online service. Let’s study each of these three steps in further detail to examine the best practices. Therefore, this article is dedicated to helping you learn how to prepare CAD files for CNC machining. 1. Optimize Tolerances. 2. Type of Material. 3. Minimize the Number of Machined Features. 4. Minimize Machined Stock Allowance. 5. Standardize Features. 6. Surface Finish. 7. Provide Adequate Strength and Stiffness. 8.

We have a solution to analyze the solids - recognizing all the holes, part sizes, applying the tool pathing, creating the CNC machine code through our post processors, etc. We connect to (create the g-code) virtually any 3-axis CNC for flat panel processing and optimization. AutoCAD does not have built-in CAM functionality and, as such, its use for CNC is limited. However, AutoCAD is often used to develop 2D profiles for laser cutting, and most laser cutting facilities accept the Autocad DXF format.

cad software for cnc machine

Stick welding of sheet metal shall be carried out using AWS A5.1/A5.1M E6013 (CWB/CSA W48-06 E4313) type electrode of diameter 5/64 inch or 2.0 mm. E6013 types electrode offer very good arc stability, easy-to-start arc, shallow penetration, and less power in arc compared to E6010 or E7018 type rods. E6013 can be used with AC, DCEP, and DCEN .

autocad to cnc machine|cnc milling machine programming software