cnc aerospace wings part factory What Is CNC Machining for Aerospace? CNC machining for aerospace is a specialized manufacturing process that uses computer numerical control (CNC) machines to produce high-precision parts for aircraft and . What is Sheet Metal Notching? Notching sheet metal involves removing unwanted metal material from the edges of a sheet metal. The most popular tool for this process is the punch press.

0 · cnc aircraft parts

1 · aircraft fuselage parts

2 · aircraft cnc machining

3 · aerospace cnc milling machine

4 · aerospace cnc machining explained

5 · aerospace cnc machining

6 · aerospace cnc machine accuracy

7 · 5 axis cnc milling

1. Gain knowledge of development of sheet metal models with an understanding of their applications. 2. Perform soldering and welding of sheet metal & welded joints. 3. Understand the Basic of workshop Practices. 4. Gaining the knowledge of power Tools and Tools.

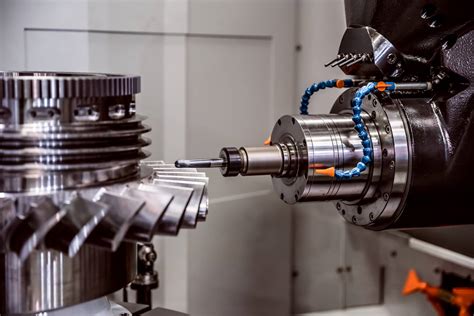

What is CNC machining and why is it used in aerospace parts manufacturing? CNC machining is a process where computer software controls the movement of factory tools and machinery, creating parts with a high level .CNC machining allows the production of strong items made of heat-resistant materials. Other applications of aerospace CNC machining include the production of cabin parts, wing ribs, fuselage components, actuators, motion controls, .

Whether its manifolds, wings, hydraulic couplings, clamps, hinges, or other proprietary components, aerospace equipment and parts found on aircraft demand the highest standards both in raw material and machining. Using state-of-the-art CNC machining equipment, qualified manufacturing services such as RapidDirect can produce aerospace prototypes and end-use components for aerospace companies. Working with aerospace .

What Is CNC Machining for Aerospace? CNC machining for aerospace is a specialized manufacturing process that uses computer numerical control (CNC) machines to produce high-precision parts for aircraft and . AN-Prototype’s CNC machine shop can provide aerospace prototypes and precision machined components to the aerospace industry using advanced CNC machining equipment. Efficient CNC machining helps achieve .

Whether your aerospace parts require 5-axis CNC machining, fine wire EDM or Plunge/Sink EDM with exacting tolerances, Owens’ machinists have the knowledge, experience, and dedication to deliver the complex components .CNC machining delivers unrivaled precision and accuracy, ensuring that aerospace parts meet exact specifications. This is especially important for critical aerospace systems, such as turbine engines, landing gear and structural .

Precision CNC machining of custom aerospace prototypes and production parts. Streamline production runs with on-demand manufacturing.

Our industrial machine shop services include aerospace parts machining and die casting aerospace products. At Minghe Casting, we have a two-pronged approach to the stratospheric material and process requirements of the . What is CNC machining and why is it used in aerospace parts manufacturing? CNC machining is a process where computer software controls the movement of factory tools and machinery, creating parts with a high level of precision.CNC machining allows the production of strong items made of heat-resistant materials. Other applications of aerospace CNC machining include the production of cabin parts, wing ribs, fuselage components, actuators, motion controls, engine housings, landing gear components, discs, and filter bodies.Whether its manifolds, wings, hydraulic couplings, clamps, hinges, or other proprietary components, aerospace equipment and parts found on aircraft demand the highest standards both in raw material and machining.

Using state-of-the-art CNC machining equipment, qualified manufacturing services such as RapidDirect can produce aerospace prototypes and end-use components for aerospace companies. Working with aerospace-grade metals and plastics, CNC machine systems can reach tolerances up to 0.002 mm.

parts cutter cnc

cnc aircraft parts

What Is CNC Machining for Aerospace? CNC machining for aerospace is a specialized manufacturing process that uses computer numerical control (CNC) machines to produce high-precision parts for aircraft and spacecraft. AN-Prototype’s CNC machine shop can provide aerospace prototypes and precision machined components to the aerospace industry using advanced CNC machining equipment. Efficient CNC machining helps achieve tolerance levels as high as 0.002 mm, creating aerospace-grade plastics and metals.

Whether your aerospace parts require 5-axis CNC machining, fine wire EDM or Plunge/Sink EDM with exacting tolerances, Owens’ machinists have the knowledge, experience, and dedication to deliver the complex components you need with the highest precision possible.CNC machining delivers unrivaled precision and accuracy, ensuring that aerospace parts meet exact specifications. This is especially important for critical aerospace systems, such as turbine engines, landing gear and structural elements, where even a slight deviation can significantly impact performance, safety and durability.Precision CNC machining of custom aerospace prototypes and production parts. Streamline production runs with on-demand manufacturing.

Our industrial machine shop services include aerospace parts machining and die casting aerospace products. At Minghe Casting, we have a two-pronged approach to the stratospheric material and process requirements of the aerospace industry.

What is CNC machining and why is it used in aerospace parts manufacturing? CNC machining is a process where computer software controls the movement of factory tools and machinery, creating parts with a high level of precision.CNC machining allows the production of strong items made of heat-resistant materials. Other applications of aerospace CNC machining include the production of cabin parts, wing ribs, fuselage components, actuators, motion controls, engine housings, landing gear components, discs, and filter bodies.Whether its manifolds, wings, hydraulic couplings, clamps, hinges, or other proprietary components, aerospace equipment and parts found on aircraft demand the highest standards both in raw material and machining.

Using state-of-the-art CNC machining equipment, qualified manufacturing services such as RapidDirect can produce aerospace prototypes and end-use components for aerospace companies. Working with aerospace-grade metals and plastics, CNC machine systems can reach tolerances up to 0.002 mm. What Is CNC Machining for Aerospace? CNC machining for aerospace is a specialized manufacturing process that uses computer numerical control (CNC) machines to produce high-precision parts for aircraft and spacecraft.

AN-Prototype’s CNC machine shop can provide aerospace prototypes and precision machined components to the aerospace industry using advanced CNC machining equipment. Efficient CNC machining helps achieve tolerance levels as high as 0.002 mm, creating aerospace-grade plastics and metals.

Whether your aerospace parts require 5-axis CNC machining, fine wire EDM or Plunge/Sink EDM with exacting tolerances, Owens’ machinists have the knowledge, experience, and dedication to deliver the complex components you need with the highest precision possible.CNC machining delivers unrivaled precision and accuracy, ensuring that aerospace parts meet exact specifications. This is especially important for critical aerospace systems, such as turbine engines, landing gear and structural elements, where even a slight deviation can significantly impact performance, safety and durability.

aircraft fuselage parts

Precision CNC machining of custom aerospace prototypes and production parts. Streamline production runs with on-demand manufacturing.

partner steel dry box

Sheet metal punching is the process of creating holes in sheet metal using a punch press or a CNC punching machine. The process involves cutting and piercing the sheet metal using dies mounted on presses.

cnc aerospace wings part factory|cnc aircraft parts