chain drive cnc machine Hey, I see several videos in Youtube, that CNC is using chain drive instead of screw or belt. Someone can share experience about it ? Most interesting is accuracy and . 14 terminals help you stay organized. Durable polymer boxes stand the tests of time and weather. Consolidates your truck's electrical wiring. Electrical Junction Boxes from Buyers Products provide an organized way to terminate and .

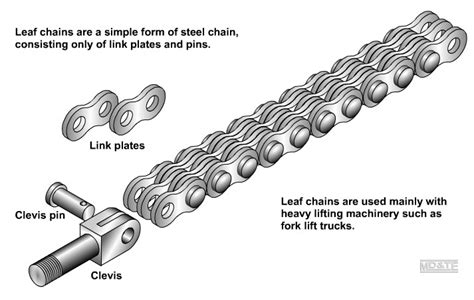

0 · leaf chain drives

1 · leaf chain drive diagram

2 · high speed stud chain drive

3 · high speed chain drives

4 · diy cnc router chains

5 · disadvantages of chain drives

6 · different types of chain drive

7 · chain drive sizes

“Tri-State has earned our respect and appreciation for the way they do business, the quality of the management staff, and the skilled craftsmen. This particular project was demanding from a scheduling standpoint, and required close coordination with multiple trades, as well as involving challenging problems that demanded immediate on-site .

leaf chain drives

Hey, I see several videos in Youtube, that CNC is using chain drive instead of screw or belt. Someone can share experience about it ? Most interesting is accuracy and . I found pretty good solution about how to protect chain drive from dust, and it looks like normal. Brother CNC do the same with ATC gearbox, to ensure, that coolant will not get .

leaf chain drive diagram

I show how to make robot chain drive sprockets, by CNC. This video has an interesting story behind it. I help out a FIRST Robotics team with some robot parts.

How the chains are routed through the gantry and fastened to the table.

The drive system plays a vital role in CNC accuracy, power, and speed on large 4 by 8 foot CNCs. Chain drive is the cheapest option (used in the Maslow and MakerMade M2). Belt drive is better, but various forms of rack .

There was a thread on DIY-CNC which dealt with chain vs belts vs racks vs screw drives, and the chain fared pretty well. But, because of other considerations like stretch and .

There are a million and one ways to build your own CNC router, depending on your tastes, budget, and application, your design choices will differ accordingly. [Steve Tyng] was well aware of this. Hey, I see several videos in Youtube, that CNC is using chain drive instead of screw or belt. Someone can share experience about it ? Most interesting is accuracy and speed, lubricating and how stepper motors like nema 34 is working with chain tensioning.

Chain drive is a type of mechanical power transmission system that uses chains to transfer power from one place to another. A conventional chain drive consists of two or more sprockets and the chain itself. The holes in the chain links fit over the sprocket teeth.

high speed stud chain drive

I found pretty good solution about how to protect chain drive from dust, and it looks like normal. Brother CNC do the same with ATC gearbox, to ensure, that coolant will not get inside - just pressurize gearbox.I show how to make robot chain drive sprockets, by CNC. This video has an interesting story behind it. I help out a FIRST Robotics team with some robot parts. How the chains are routed through the gantry and fastened to the table. The drive system plays a vital role in CNC accuracy, power, and speed on large 4 by 8 foot CNCs. Chain drive is the cheapest option (used in the Maslow and MakerMade M2). Belt drive is better, but various forms of rack and pinion are the best for the X and Y axes.

There was a thread on DIY-CNC which dealt with chain vs belts vs racks vs screw drives, and the chain fared pretty well. But, because of other considerations like stretch and pinion wear, it was dismissed in favor of rack and pinion drives for long axes. A chain with less power loss than 10% is far more expensive than a screw, believe me. It seems to me that a tight cable or chain would not have very much backlash and be a hell of a lot cheaper. do any of you out there have such a drive on your machine?When designing a chain drive, the transmitted power P, the speed of the small sprocket m, the speed of the large chain z or the transmission ratio z, the load situation and the use conditions are generally known.

There are a million and one ways to build your own CNC router, depending on your tastes, budget, and application, your design choices will differ accordingly. [Steve Tyng] was well aware of this.

Hey, I see several videos in Youtube, that CNC is using chain drive instead of screw or belt. Someone can share experience about it ? Most interesting is accuracy and speed, lubricating and how stepper motors like nema 34 is working with chain tensioning.

Chain drive is a type of mechanical power transmission system that uses chains to transfer power from one place to another. A conventional chain drive consists of two or more sprockets and the chain itself. The holes in the chain links fit over the sprocket teeth. I found pretty good solution about how to protect chain drive from dust, and it looks like normal. Brother CNC do the same with ATC gearbox, to ensure, that coolant will not get inside - just pressurize gearbox.I show how to make robot chain drive sprockets, by CNC. This video has an interesting story behind it. I help out a FIRST Robotics team with some robot parts. How the chains are routed through the gantry and fastened to the table.

The drive system plays a vital role in CNC accuracy, power, and speed on large 4 by 8 foot CNCs. Chain drive is the cheapest option (used in the Maslow and MakerMade M2). Belt drive is better, but various forms of rack and pinion are the best for the X and Y axes. There was a thread on DIY-CNC which dealt with chain vs belts vs racks vs screw drives, and the chain fared pretty well. But, because of other considerations like stretch and pinion wear, it was dismissed in favor of rack and pinion drives for long axes. A chain with less power loss than 10% is far more expensive than a screw, believe me.

It seems to me that a tight cable or chain would not have very much backlash and be a hell of a lot cheaper. do any of you out there have such a drive on your machine?

metal trim on victorian house

high speed chain drives

diy cnc router chains

disadvantages of chain drives

The Tuf-tite 4HD2 4-Hole Distribution Box comes complete with a lid. The Lid is 11" x 11". The Box is 15-1/2" tall and there is a 2" drop between inlet and outlets. The Distribution box is Used with 4" Pipe. Extra Fittings Sold Separately: B07RGRV8J6.

chain drive cnc machine|chain drive sizes