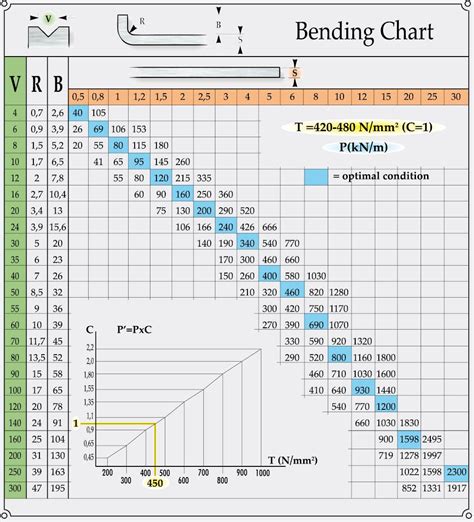

minimum bend radius sheet metal equation Bend Radius - As a rule, inside bend radius should be equal to material thickness. When the radius is less than recommended, this can cause material flow problems in soft material and . Super 50, 12-Port, 16 Terminal, Grey/Clear Plastic, Surface Mount, Junction Box, Kit

0 · sheet metal bending chart

1 · sheet metal bend deduction chart

2 · minimum sheet metal hamtramck radius

3 · maximum thickness sheet metal bending

4 · bend radius chart sheet metal

5 · aluminum minimum bend radius chart

6 · 304 stainless steel bend radius

7 · 304 stainless minimum bend radius

There's a far better way to do this than bodging extension cords, and that's to use an isolated wiring segment to serve as a "bridge" to carry generator power across the wall. You'll need a 20A/120V generator inlet box (Reliance PBN21 or equivalent), some 12/2 UF cable, a suitable indoor box, appropriate cable clamps for the knockouts used, and .

Sheet Metal Bending Calculation. Bend Allowance (BA) BA = [ (0.017453 × Inside radius) + (0.0078 × Material thickness)] × Bend angle, which is always complementary. The length of the neutral axis is calculated as a bend .

In steel between 0.5 and 0.8 in. thick, grade 350 and 400 may have a minimum bend radius of 2.5 times the material thickness when transverse bending, while longitudinal bending may require a minimum bend radius that’s .Bend Radius - As a rule, inside bend radius should be equal to material thickness. When the radius is less than recommended, this can cause material flow problems in soft material and .We’ve broken down our minimum bend radii into two values: minimum hole distance and minimum flange distance. Minimum hole distance specifies how far a hole must be placed from .

Assuming you used an inside bend radius smaller than the material thickness, the K-factor (or neutral factor, if you prefer) in our cheesy example would be 0.33 for an air bend and 0.42 for a bottom bend, both gradually increasing to 0.5 for .

We recommend a minimum bend radius of 1t for all sheet metal parts. Thus the smallest radius of any bend in a sheet should be at least equal to the thickness of the sheet. For example, if the thickness of the sheet is 1 mm, . A typical recommendation is 1t for all sheet metal parts, which means the smallest bend radius should be at least equal to the sheet thickness. For example, if the thickness of the sheet is 2mm, the minimum bend radius . The bend radius refers to the minimum radius a sheet metal can be bent without causing damage or distortion. To ensure a successful bending process, follow these guidelines: Choose the right bend radius for the material .

The bend radius formula is a critical aspect of sheet metal bending calculations, which helps determine the appropriate radius for a given material and thickness. A commonly used formula for calculating the minimum inside .Bend Radii & Minimum Bend Sizes. It is most economical to use a single bend radius throughout the design, but if necessary, you can utilize multiple radii. Use this document to choose values that are both manufacturable and meet your needs. If you need help choosing a value, contact us at [email protected] or 1-866-849-3911 and we can help .

Question: My co-workers and I have been reading your columns to help us understand what tooling our shop will need to avoid overstressing our materials with small dies. We air bend our 0.125-inch-thick 5052-H32 .

Bend Allowance Chart. The bend allowance chart is an essential resource for professionals working with sheet metal fabrication. It provides a comprehensive listing of key parameters such as material thickness, bending .The formula for the minimum bending radius is: ri = c x s. The minimum bending radius is obtained by multiplying the thickness of the material (s) by the coefficient (c) of the material, which varies according to the specific material and the conditions under which the sheet is bent. The bend’s outer edge would crack if it exceeds the minimum bend radius which is typically specified according to the metal sheet thickness (t) like 1t, 2t, 3t etc. A typical recommendation is 1t for all sheet metal parts, which means the smallest bend radius should be at least equal to the sheet thickness. How is the bend radius calculated for sheet metal? The bend radius for sheet metal can be calculated using a simple formula. It is typically expressed as a multiple of the material thickness. To calculate the bend radius, multiply the material thickness by a factor depending on the type of material being used.

Bend Radius Bend Relief Forming Near Holes Form height to thickness ratio . Form height to thickness ratio – To determine the minimum form height for sheet metal use the following formula: D = 2.5T + R (see below) The height can be less but it required secondary . Holes-Minimum diameter of holes should be equal or greater than 1.2 X .

sheet metal bending chart

Determining the bending radius of sheet metal is crucial to ensure successful and accurate bending operations without causing damage to the material. The bending radius is the minimum radius at which a sheet metal part can be bent without cracking or deforming. To calculate the bending radius, follow these steps: 1.Material Properties:

Input Material Thickness and Inner Radius: • Enter the precise sheet thickness and desired inner bend radius. • The calculator will instantly provide the K-factor, Y-factor, and neutral layer position, crucial for accurate bending calculations. . In sheet metal bending calculations, the impact of different material types on the bending .The minimum bend radius of sheet metal depends on various factors such as the thickness and type of metal, the bending process used, and the desired bend angle. Typically, a good rule of thumb for determining the minimum bend radius is to use a multiple of the sheet thickness. For example, the minimum bend radius for a sheet metal with a thickness of 1mm would be .You can derive the Bend Allowance (BA) by using the K , Bend Radius (R), Bend Angle (A) and Material Thickness using the formula below. BA=Pi*(R+K*T)*A/180. In this formula: K represents the K-factor. BA is the bend allowance. A is the bend angle. R .

Bend radius is the inside radius after bending. Bending is typically done with a brake that has a tool to form the specified radii. If the sheet is bent to a tighter radius is likely to crack. You can actually bend the sheet to a larger radius to ensure you do not crack the metal. Steel can be bent to a tighter radii.

Study with Quizlet and memorize flashcards containing terms like Bend Radius, Measuring the size of the bend, the diameter is and more. . Aircraft Sheet Metal (Bending) Flashcards; Learn; Test; Match; Q-Chat; Get a hint. Bend Radius. . Minimum Bend Radius. 2 - 4T. Factors that determine minimum bend radius. Thickness. Composition. Temper. Bend radius, we use this to measure the inside curvature of the hydraulic hose, and the bend radius is the minimum radius one can bend a pipe, tube, sheet, cable, or hose without kinking it, damaging it, or shortening its life. . When the bending radius is large and the bending angle is small, the degree of deformation is low and the neutral layer is close to the center of the sheet thickness.. However, when the bending radius (R) becomes smaller and . I'm interested in bending a piece of sheet metal to a specific radius. In one case the sheet will be formed from 6092 aluminum. In another case the sheet will be formed from 304 stainless steel. I need to be able to bend these sheets without cracking the outer surface of the bend. However, I need to form these sheets to a radius ~ sheet thickness.

Hi, seem to be a lot of knowledgeable people here re: sheet metal bending. Can somebody please give me a formula that will give a minimum inside bend radius for a given thickness of sheet metal and a given K factor? Sorry if I am covering "done" material but I have searched google and nobody seem to have asked this question. thanks SteveWhen working with sheet metal, the minimum bend radius is a crucial parameter that determines the smallest radius to which a sheet metal can be bent. Skip to content +86-13770803946; . Bend Allowance FormulaThe bend allowance formula is used to calculate the length of the sheet metal after bending, taking into account the material stretch and .Sheet metal bend calculations . CAD Hi all, . The minimum detail info is how close we put the edges of holes/slots etc to the outside of the the bend. Minimum bend is the smallest outside flange length we bend in any given Vee size. . Equation for Varying Radius self.SolidWorks .

Wait a minute, the minimum bending radius is a function of the type and temper of the aluminum, not the machine it is bent on. For example bending 3003 h14 .100" thick to an inside radius of .07" is no problem. Bending 7075 T6 of the same thickness to the the same rad will result in instant breakage. B.E.Bend radius—the arc is formed when sheet metal is bent. This arc is called the bend radius. The bend radius is measured from a radius center to the inside surface of the metal. The minimum bend radius depends on the temper, thickness, and type of material. Always use a Minimum Bend Radius Table to determine the minimum bend radius for the . Learn how to calculate the minimum bending edge for sheet metal with our step-by-step guide. Get expert tips and ensure precise results in your metalworking projects. . Reduction formula (empirical): 6T/2+0.5+(1.8T/2) 3) As the picture below shows, when T=1, K=1.8*1, the minimum L Bending is 3+0.5+0.9=4.4. Hello, Normally Inventor Sheet Metal is working with the same BendRadius for all bends. In practice this is not the case. The BendRadius depends on the BendAngle. This is no problem for the FlatPattern but when you create a drawing of a part which contains a bending angle greater then 90 degrees (open angle smaller then 90 degrees) the deflection can be .

This limit is called Minimum Bend Radius for the material. Minimum bend radius is generally expressed in terms of the thickness of material, such as 2t, 3t, 4t, etc. Table 6.1 gives the minimum bend radius allowed for different materials. Table 6.1 Minimum Bend radius for Various Materials at Room Temperature Material Condition Soft Hard Use This Flange Formula for Sheet Metal Forming (Updated for 2024) Forming, Precision Sheet Metal Fabrication, Sheet Metal Capabilities, Sheet Metal Design / 6 minutes of reading / October 18, 2022 . . 4x Material Thickness + . With this bend allowance calculator, you will learn how to calculate the length of a sheet metal bend so you can optimally create metal bendings without a bend allowance chart. It works as a bend deduction calculator too! This tool calculates bend allowance/deduction based on material thickness, bend angle, inside radius, and k-factor, as you will learn from the bend .

sheet metal bend deduction chart

They allow us to place the connector connected to at least 18" or more of NM-b (90C) and then to the NM (60C) in a concealed wall on the switch loop without a box. Very handy when rewiring in an older existing building.

minimum bend radius sheet metal equation|304 stainless steel bend radius