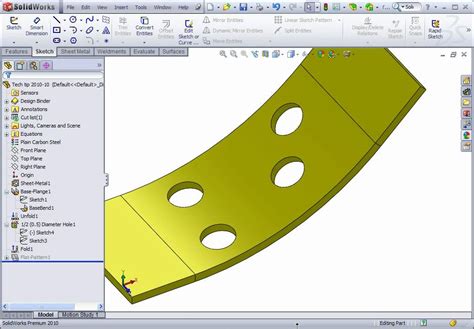

curved sheet metal part solidworks Has anyone had expirience with using solidworks to create curved sheet metal . What happens if you swallow a braces bracket? Swallowing a braces bracket is rare, but it does happen. The good news is: more often than not, you won’t experience any serious repercussions from a swallowed braces bracket .

0 · sheet metal bending in SolidWorks

1 · curved cylinder in SolidWorks

2 · SolidWorks sheet metal round bend

3 · SolidWorks sheet metal flange

4 · SolidWorks sheet metal edge flange

5 · SolidWorks sheet metal cylinder

6 · SolidWorks sheet metal curved bend

7 · SolidWorks fold sheet metal

The distribution box serves as the load centre and distributor of electrical power. A distribution box ensures that electrical supply is distributed in the building, also known as a distribution board, panel board, breaker panel, or electric panel.

As far as I know the only way to make a sheet metal part bent along a spline is with lofted bend. You would sketch the profile you want, use convert entities to copy it to a parallel plane, then .This can be done using Sheet Metal functionality in SOLIDWORKS. .

Has anyone had expirience with using solidworks to create curved sheet metal .

canada: cnc machining custom manufacturer -news -china -chinese -alibaba -amazon

To create a sheet metal part with cylindrical faces: Sketch an open contour arc. The arc can also be tangent to a line. Single open contours can be used for extrudes, revolves, sections, paths, . Sheet metal is a thin, flat piece of metal formed during an industrial process that is used for many everyday applications.This can be done using Sheet Metal functionality in SOLIDWORKS. Specifically the "Sketch Bend" command (GoEngineer - SOLIDWORKS: Sheet Metal Sketch Bend). I will caution you though that using Sketch Bends can be difficult if you . A step-by-step guide on how to create the shade holder part in the lamp model shown keeping cut outs in curved surfaces straight and true for a genuine flat pattern.

When adding a cut to a folded sheet metal part, select Normal cut to ensure that the cut is created normal to the sheet metal thickness. Creating Sheet Metal Parts with Cylindrical Faces. .

sheet metal bending in SolidWorks

To create a sheet metal part, you sketch an open profile and use the base flange feature to create the thin feature and the bends. You can add flanges to your sheet metal part with corners that are automatically mitered. First you add a .Has anyone had expirience with using solidworks to create curved sheet metal panels, with returns on all sides? I am struggling to add the returns to the top and bottom of the curved .

I'm seeking help from expert for the modeling of a sheetmetal part. I'm stuck with that shape of modeling for few days. I'm showing it with the surface feature for the easy of .I made a d=1mm cutout over the rolled sheet metal, unfold, cutout a d=10,2 mm and fold again. Is it correct or is there a better workaround? If I don't make a perfect circle.

As far as I know the only way to make a sheet metal part bent along a spline is with lofted bend. You would sketch the profile you want, use convert entities to copy it to a parallel plane, then you can use those two sketches as your profiles for a lofted bend using the formed manufacturing method.

To create a sheet metal part with cylindrical faces: Sketch an open contour arc. The arc can also be tangent to a line. Single open contours can be used for extrudes, revolves, sections, paths, guides, and sheet metal. Typical open contours are sketeched with lines or other sketch entities. Sheet metal is a thin, flat piece of metal formed during an industrial process that is used for many everyday applications.

This can be done using Sheet Metal functionality in SOLIDWORKS. Specifically the "Sketch Bend" command (GoEngineer - SOLIDWORKS: Sheet Metal Sketch Bend). I will caution you though that using Sketch Bends can be difficult if you want to make a full round bend like this as it must leave some amount, if only a sliver, of flat section on either .

A step-by-step guide on how to create the shade holder part in the lamp model shown keeping cut outs in curved surfaces straight and true for a genuine flat pattern.When adding a cut to a folded sheet metal part, select Normal cut to ensure that the cut is created normal to the sheet metal thickness. Creating Sheet Metal Parts with Cylindrical Faces. Adding Walls to Sheet Metal Parts. Creating Elliptical Bends. You can sketch an ellipse and a create sheet metal part that has elliptical bends. Drawings of .To create a sheet metal part, you sketch an open profile and use the base flange feature to create the thin feature and the bends. You can add flanges to your sheet metal part with corners that are automatically mitered. First you add a notch to limit the propagation of the miter flange. Then you add and dimension the sketch for the miter flange.

Has anyone had expirience with using solidworks to create curved sheet metal panels, with returns on all sides? I am struggling to add the returns to the top and bottom of the curved front face. Please see the plan view on the attached drawing for the curve details. I'm seeking help from expert for the modeling of a sheetmetal part. I'm stuck with that shape of modeling for few days. I'm showing it with the surface feature for the easy of understanding.

cantex weatherproof electrical box

I made a d=1mm cutout over the rolled sheet metal, unfold, cutout a d=10,2 mm and fold again. Is it correct or is there a better workaround? If I don't make a perfect circle. As far as I know the only way to make a sheet metal part bent along a spline is with lofted bend. You would sketch the profile you want, use convert entities to copy it to a parallel plane, then you can use those two sketches as your profiles for a lofted bend using the formed manufacturing method.To create a sheet metal part with cylindrical faces: Sketch an open contour arc. The arc can also be tangent to a line. Single open contours can be used for extrudes, revolves, sections, paths, guides, and sheet metal. Typical open contours are sketeched with lines or other sketch entities. Sheet metal is a thin, flat piece of metal formed during an industrial process that is used for many everyday applications.

This can be done using Sheet Metal functionality in SOLIDWORKS. Specifically the "Sketch Bend" command (GoEngineer - SOLIDWORKS: Sheet Metal Sketch Bend). I will caution you though that using Sketch Bends can be difficult if you want to make a full round bend like this as it must leave some amount, if only a sliver, of flat section on either . A step-by-step guide on how to create the shade holder part in the lamp model shown keeping cut outs in curved surfaces straight and true for a genuine flat pattern.

curved cylinder in SolidWorks

SolidWorks sheet metal round bend

When adding a cut to a folded sheet metal part, select Normal cut to ensure that the cut is created normal to the sheet metal thickness. Creating Sheet Metal Parts with Cylindrical Faces. Adding Walls to Sheet Metal Parts. Creating Elliptical Bends. You can sketch an ellipse and a create sheet metal part that has elliptical bends. Drawings of .To create a sheet metal part, you sketch an open profile and use the base flange feature to create the thin feature and the bends. You can add flanges to your sheet metal part with corners that are automatically mitered. First you add a notch to limit the propagation of the miter flange. Then you add and dimension the sketch for the miter flange. Has anyone had expirience with using solidworks to create curved sheet metal panels, with returns on all sides? I am struggling to add the returns to the top and bottom of the curved front face. Please see the plan view on the attached drawing for the curve details. I'm seeking help from expert for the modeling of a sheetmetal part. I'm stuck with that shape of modeling for few days. I'm showing it with the surface feature for the easy of understanding.

cancam cnc machines

SolidWorks sheet metal flange

Sheet metal gauge determines the thickness and strength of HVAC ductwork, impacting its ability to withstand pressure and airflow. Choosing the right thickness is crucial for ensuring compliance with safety regulations and meeting minimum requirements set by codes.

curved sheet metal part solidworks|curved cylinder in SolidWorks