cutting 20 gauge sheet metal There are about a bajillion mechanical cutting tools, from the massive hydraulic shears, to foot shears, cut off wheels, and saws. We will cover the basic tools that the typical entry-level . See more VANCE METAL FABRICATORS, INC. APPLICATION FOR EMPLOYMENT. We are an Equal Opportunity Employer. We consider all applications for all positions without regard to race, color, religion, gender, national origin, age, sexual orientation, genetic predisposition or carrier status, disability, marital status, pregnancy, veteran status, or any other legally protected class or status.

0 · 20 gauge sheet metal thickness

1 · 20 gauge sheet metal price

2 · 20 gauge sheet metal lowe's

3 · 20 gauge sheet metal 4x8

4 · 20 gauge metal thickness

5 · 20 gauge galvanized steel sheet

6 · 20 gauge galvanized sheet metal

7 · 20 ga galvanized sheet price

Custom Welding, Metal Fabrication, Electroplating, Drafting, Polishing and Powder Coating. Take the time to stop in at Valley Metal Ltd. and be greeted with a firm handshake, a fair estimate and a project that is delivered on time and on budget.

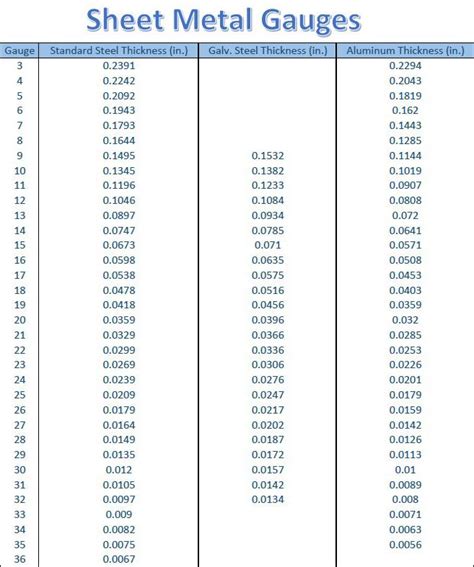

The most important factor to consider when working with sheet metal is the gauge. The lower the number, the thicker the metal is. Most sheet metal cutting tools are limited to 16-gauge and thinner. While 14-gauge is still sheet metal, but in common forms technically so is 11-gauge metal (which is 1/8” thick), and . See moreThe most common hand tools for cutting sheet metal are hand shears, also known as “tin snips”. There are several versions, from the old school cleaver type, to the much better scissor . See moreThere are about a bajillion mechanical cutting tools, from the massive hydraulic shears, to foot shears, cut off wheels, and saws. We will cover the basic tools that the typical entry-level . See moreYou may be thinking that slicing is the same a shearing, but it isn’t. There are all kinds of slicing tools on the market for sheet metal and they do a heck of a lot more than straight . See more

Learn how to cut sheet metal with our step-by-step guide showing multiple techniques for precise, safe cuts for your DIY projects. When cutting sheet metal, it’s crucial to .

Today I’ll go over three different tools you can use to cut sheet metal and plate. One of the fastest, most precise sheet metal cutting methods is to cut with a high-power laser. There are modern laser machines available that can cut and format automatically . Depending on the pattern and type of sheet metal, you can use several different kinds of equipment to make a cut. You can use an electric .

There are many ways to cut sheet metal, which one you need to use depends on the project. The following is a primer of tools and techniques for cutting sheet metal. The most important factor to consider when working with sheet metal is the gauge. The lower the number, the thicker the metal is.

Learn how to cut sheet metal with our step-by-step guide showing multiple techniques for precise, safe cuts for your DIY projects. When cutting sheet metal, it’s crucial to use the correct methods to get the best results while staying safe. A circular saw is ideal for cutting all gauges of sheet metal, even the thickest of sheets, and it is ideal for cutting straight lines. If you have pieces that need to be separated into various sections, then this is one of the best methods that you have at your disposal. Today I’ll go over three different tools you can use to cut sheet metal and plate. One of the fastest, most precise sheet metal cutting methods is to cut with a high-power laser. There are modern laser machines available that can cut and format automatically once you set the track. The speed and orientation of cutting with laser tools are limited within 2D.

Depending on the pattern and type of sheet metal, you can use several different kinds of equipment to make a cut. You can use an electric saw for simple lines, or you can try tin snips, dremels, or metal nibblers for complex designs with curved lines. We’ll show you power tool tips and techniques for cutting the types and thicknesses of metal that DIYers handle the most. And whether you’d like to build custom cars or just fix a cracked lawn mower deck, learning to weld gives your DIY game a serious boost. Avoid accidentally bending, scoring, or gouging the metal in your next DIY project when you follow this technique for how to cut sheet metal.Most of our DIY customers successfully use them. They can easily cut through 26 or 29 gauge metal panels, and probably heavier. But there is a RIGHT way to do it! We highly recommend reading this article and watching the videos before you start snipping away at your new metal roof panels. It’ll make the job much better for you!

Almost any type of saw can cut through 20-gauge sheet metal. A saw is a tool with a serrated blade. The blades are normally relatively large to accommodate thickness and size of the sheet metal. Some examples of saw tools used to cut through sheet metal include hacksaws, table saws and circular saws.

20 gauge sheet metal thickness

20 gauge sheet metal price

There are many ways to cut sheet metal, which one you need to use depends on the project. The following is a primer of tools and techniques for cutting sheet metal. The most important factor to consider when working with sheet metal is the gauge. The lower the number, the thicker the metal is.

Learn how to cut sheet metal with our step-by-step guide showing multiple techniques for precise, safe cuts for your DIY projects. When cutting sheet metal, it’s crucial to use the correct methods to get the best results while staying safe.

A circular saw is ideal for cutting all gauges of sheet metal, even the thickest of sheets, and it is ideal for cutting straight lines. If you have pieces that need to be separated into various sections, then this is one of the best methods that you have at your disposal.

Today I’ll go over three different tools you can use to cut sheet metal and plate.

One of the fastest, most precise sheet metal cutting methods is to cut with a high-power laser. There are modern laser machines available that can cut and format automatically once you set the track. The speed and orientation of cutting with laser tools are limited within 2D. Depending on the pattern and type of sheet metal, you can use several different kinds of equipment to make a cut. You can use an electric saw for simple lines, or you can try tin snips, dremels, or metal nibblers for complex designs with curved lines. We’ll show you power tool tips and techniques for cutting the types and thicknesses of metal that DIYers handle the most. And whether you’d like to build custom cars or just fix a cracked lawn mower deck, learning to weld gives your DIY game a serious boost. Avoid accidentally bending, scoring, or gouging the metal in your next DIY project when you follow this technique for how to cut sheet metal.

Most of our DIY customers successfully use them. They can easily cut through 26 or 29 gauge metal panels, and probably heavier. But there is a RIGHT way to do it! We highly recommend reading this article and watching the videos before you start snipping away at your new metal roof panels. It’ll make the job much better for you!

20 gauge sheet metal lowe's

20 gauge sheet metal 4x8

Here are 12 of the most common types of CNC machines. Each performs somewhat different machining operations with few human errors, high-speed processes, and high-quality results. 1. CNC Milling Machine. CNC milling machines use rotating cutting tools to remove material from a workpiece.

cutting 20 gauge sheet metal|20 gauge sheet metal thickness