cnc machine zero point manufacturer Method 2: Use a 3D Taster. Another very common, but more modern and slicker method than the above 2 edgefinders, is to use a “3D Taster”.. 3D Tasters (often now called “3D Sensors”, but the original .

If you’re caught stopping inappropriately in a yellow box, you will usually receive a fine, rather than points on your licence. However, if your actions lead to an accident, you may be charged with a driving offence, whereby you .

0 · zero position cnc

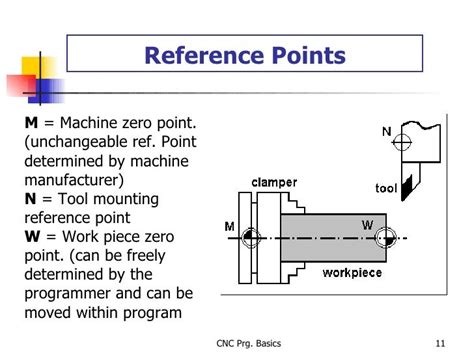

1 · what are workpiece reference points

2 · offset meaning in cnc programming

3 · offset in cnc lathe

4 · machine zero cnc

5 · gcode set machine zero

6 · gcode g28

7 · cnc tool offsets explained

$37.07

Whether it's intricate components or large-scale projects, our skilled team is dedicated to delivering unparalleled precision and quality. From concept to creation, we pride ourselves on offering tailored solutions, utilizing advanced CNC machinery to craft impeccable parts with .

This blog post will examine the significance of the zero point in CNC manufacturing, delve into the various techniques for setting it, discuss the importance of calibration, and explore how .Precise mounting of DynoLock bases and use with DynoGrip self-centering vises. Mate’s CNC workholding solutions offer best-class accuracy and repeatability. Learn more about our .Jergens Zero Point System allows you to fix, position, and clamp in a single step, cutting set up times by up to 90%. Available with either pneumatic or hydraulic release, these positive .Best Quality mechanical zero point base plate and workholding China Manufacturer & Supplier. Saving set time and reducing machine tool down time; Zero point base plate 4-point clamping design, 14kN power clamping force .

Method 2: Use a 3D Taster. Another very common, but more modern and slicker method than the above 2 edgefinders, is to use a “3D Taster”.. 3D Tasters (often now called “3D Sensors”, but the original .

zero position cnc

what are workpiece reference points

Modern manufacturing relies on precision, efficiency, and accuracy to stay competitive in a fast-paced world. One such development leading the way in precision manufacturing is the Zero Point Clamping System. This advanced .Real-Life Examples of CNC Machine Zero Point Optimization (200 words)\ 6.1 Case Study 1: XYZ Manufacturing\ 6.2 Case Study 2: ABC Machining Co.\ . CNC machining is a versatile manufacturing technology that can be used for a wide range of applications. Common examples include components for the aerospace, automotive, medical industries and etc It is important to note that the specific steps and procedures for setting the zero point may vary depending on the machine or software being used. Manufacturers provide detailed instructions in the machine's operating manual, which should be followed closely for accurate results. . Setting the zero point on a CNC lathe is a crucial step in . Discover 7 essential ways for setting Part Zero in CNC routers to improve precision and efficiency. . making them crucial in modern manufacturing. These machines bridge the gap between digital design and real-world products. . Whether you’re using a high-end production CNC router or a DIY CNC router, establishing this point determines how .

Fanuc alarm: 405 - SERVO ALARM: (ZERO POINT RETURN FAULT) CNC Machine Control Manufacturer. Fanuc. Control Model. 16/18/21, 16i/18i/21i, 160i/180i/210i, , 0i. 405 - SERVO ALARM: (ZERO POINT RETURN FAULT) Alarm Description. Position control system fault. Due to an NC or servo system fault in the reference position return, there is the .Study with Quizlet and memorize flashcards containing terms like What rotational axis rotates around the Y axis?, What uses three axes to define the location of any point in three-dimensional space?, How are the locations of the Cartesian axes on CNC machines determined? and more. Machine Zero Machine reference point or machine zero or home position, they all refer to the same location at the machine - its origin. This origin is defined by the machine manufacturer and for normal purposes, this location is fixed. In theory, all tool motions programmed should originate from this fixed machine zero location.

Company profile Shenzhen Jingzuan Precision Hardware & Tools Co., Ltd. Was established in 2000 and is dedicated to manufacture 3A fast positioning fixture system, zero-point fast positioning clamping system, ball lock fast-installation fixture system, numerical control machine clamping chuck, guide sleeve and tooling and fixture.The machine zero may seem random, it's used by the manufacturer as a starting point, then the G54 G55 etc are offset from that point and used to make parts. Of you smacked the machine and the carriage moved on the screw, it could be mechanically off and create the situation you have (don't ask me how I know).

offset meaning in cnc programming

Study with Quizlet and memorize flashcards containing terms like Which of the following allows the CNC control to translate the directions in a program into movement of the machine components., 3-dimensional Cartesian coordinate system has three axes, which are ______., On a horizontal number line, positive numbers are to the ______ of zero. and more.About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright .

3X M6x0,75 25 40 PART IS LOCATED IN A VISE WORK OFFSET SETTINGS MACHINE ZERO REFERENCE POINTS During every part setup, two major locations, called reference points, have to be carefully managed. Those are points that establish the relationship between the known reference point of the machine (machine zero) and the unknown reference . I'm wondering if it's possible to change a machines zero return. A Doosan VT1100, with a fanuc 21i-tb control panel. When the machine returns to it's zero return position with a G28, it's nowhere near it's Z limit. In fact a lot of programs .The Zero Point Clamping System is a modular clamping system that is used in CNC machining, milling, and robotics applications. It operates using the principle of a vacuum seal and is capable of firmly securing the workpiece without the need for any mechanical clamping.Machine Zero:\ Machine zero, also known as the machine home position, is the reference point that defines the coordinate system for CNC machines. It represents the origin of the machine's X, Y, and Z axes. When the machine is powered on, it seeks this position as its home base, allowing for consistent measurements and movements. Workpiece Zero .

sdi distribution box

Study with Quizlet and memorize flashcards containing terms like Which of the following allows the CNC control to translate the directions in a program into the movements of the machine components?, Which of the following does the programmer define as the origin of measurements on the workpiece?, Machine zero can be located in __________ depending on manufacturer . The ABS zero and the machine zero are the same thing. Actually the absolute positioning is simply a battery backup for the machine position. Finding the source of the interlock may be best left to the service tech. If you're not familiar with poking around in the ladder program, you can waste a lot of time looking for it.Machine Zero Point (MCS) Machine zero point is fixed by machine manufacturer and cannot be changed. Workpiece Zero Point (WCS) Workpiece zero point is set by cnc machinists, he can set this point on his will, but mostly Workpiece zero point is located at workpiece front face. All programming dimensions are taken from workpiece zero point when a cnc program is made .Zero setting is the foundation of CNC machining and involves setting the starting point of the machine's coordinate system. This reference point, often called Machine Zero or Datum, is used as a reference for all subsequent tool paths and measurements. 2. Importance of Zero Setting:\

• machine zero point, m: machine zero point is the starting point (zero point) of a machine's non-variable - non-shiftable coordinate system. this point is fixed by the machine manufacturer with riders and is the starting point for all additional coordinate systems and reference points on .The ZERO CLAMP zero point clamping system is the modern alternative to the conventional T-slot table: Drastically reduces the setup times and increases your machine capacity. . Furthermore, the machining process can be interrupted for intermediate measurements on the measuring machine (the clamping studs are not removed for this purpose .Study with Quizlet and memorize flashcards containing terms like Which of the following does the programmer define as the origin of measurements on the workpiece?, _____ or program zero point is more common as a reference point than using machine coordinates., Which of the following allows the CNC control to translate the directions in a program into the movements of .

The machine zero point is a fixed point on the machine tool and is determined by the machine tool manufacturer. It is the reference point for all other coordinate systems, such as the workpiece coordinate system, the programming coordinate system, and the machine reference point. . Smartlathe is one of the leading manufacturers of CNC machine .CNCmakers Limited Address: No.168, Xiadu Road, Haizhu District, Guangzhou, China 510300 Tel: +86-138-24444158 Fax: +86-20-84185336 Email: [email protected] site .

As the zero-point system is the base that creates the modular system, users should look for systems that adapt to several different machine tool tables, faceplates, pallets, etc., without requiring customization or modification. Customizations add to the price and create another variable when properly locating the zero-point base.

offset in cnc lathe

Stainless Stee. ICP record encoding:沪ICP备05040313号-1 copyright:AVIC Shanghai Yaohua Weighing System Co ., Ltd technology:中航国际金网(北京)科技有限公司

cnc machine zero point manufacturer|cnc tool offsets explained