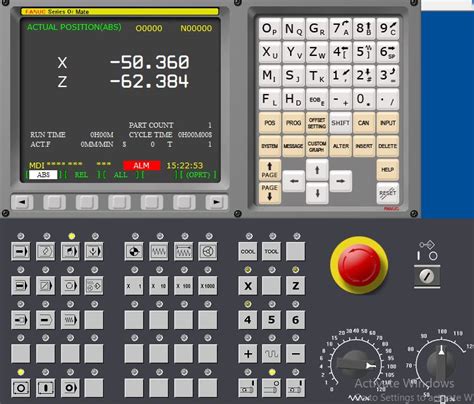

cnc machine button CNC turning, CNC milling etc CNC machining work must programmed in CNC Machine operation panel to control their actions. This article explained all keys mean. $28.99

0 · cnc machine keys meaning

1 · cnc machine keys

2 · cnc machine control panel

3 · cnc machine buttons explained

4 · cnc machine buttons and keys

5 · cnc machine button reset

6 · cnc control panel buttons

7 · cnc buttons meaning

Our selection includes: Flat Jaw Sheet Metal Pliers: Ideal for straight bends and corners, providing precision and control. Offset Jaw Sheet Metal Pliers: Designed for reaching into tight spaces and creating bends close to edges.

Understanding the CNC machine buttons is integral to efficient and safe operation. The buttons covered in this guide represent the core functions necessary to effectively run a CNC machine. .

CNC turning, CNC milling etc CNC machining work must programmed in CNC Machine operation panel to control their actions. This article explained all keys mean.Power On/Off Button: This button is used to turn the CNC machine on or off, allowing operators to start or shut down the machine safely. Start/Stop Button: The start/stop button initiates or stops the machining process. With the press of a button, the machine manuals become available to the operator right on the CNC control. This includes a programming assistant that describes the canned . FUNCTION OF MDI PANEL KEYS. CNC machines need to perform many different operations as needed, many types of keys have to be used on the computer control panel to perform this type of operation.

With the manual mode, the operator of a CNC machine is allowed to press buttons, turn handwheels, and activate switches in order to attain the desired machine function. The activation of each button or switch in the . To avoid surges, most CNC machines have at least two different power buttons, one for power to the control and another for power to the machine tool itself. The control panel power button must be pressed first and activates .

cnc machine keys meaning

Most CNC machines also have a jog function, allowing axis motion to be caused by a joystick or push button. Most have a button to turn the spindle on and off, as well as a .Discover the benefits of CNC control panels and pendants for CNC machining. Learn about different types, features, and how to choose the right one for you. Read more now! Learn about the potential hazards of CNC machines, their safety features, and guidelines that will enable you to safely work with these machines, preventing accidents in the workplace. 1. Noise. 2. Chips. 3. Moving .

Understanding the CNC machine buttons is integral to efficient and safe operation. The buttons covered in this guide represent the core functions necessary to effectively run a CNC machine. Of course,the specifics of these buttons can vary slightly between different models and manufacturers of CNC machines. But,with this foundation,you should . CNC turning, CNC milling etc CNC machining work must programmed in CNC Machine operation panel to control their actions. This article explained all keys mean.Power On/Off Button: This button is used to turn the CNC machine on or off, allowing operators to start or shut down the machine safely. Start/Stop Button: The start/stop button initiates or stops the machining process. With the press of a button, the machine manuals become available to the operator right on the CNC control. This includes a programming assistant that describes the canned cycles and a G- and M-code listing. If an alarm pops up, the same button will describe the alarm and its possible causes.

FUNCTION OF MDI PANEL KEYS. CNC machines need to perform many different operations as needed, many types of keys have to be used on the computer control panel to perform this type of operation.

With the manual mode, the operator of a CNC machine is allowed to press buttons, turn handwheels, and activate switches in order to attain the desired machine function. The activation of each button or switch in the manual mode has an immediate response. To avoid surges, most CNC machines have at least two different power buttons, one for power to the control and another for power to the machine tool itself. The control panel power button must be pressed first and activates the control screen and control panel. Most CNC machines also have a jog function, allowing axis motion to be caused by a joystick or push button. Most have a button to turn the spindle on and off, as well as a rheostat to control spindle speed.Discover the benefits of CNC control panels and pendants for CNC machining. Learn about different types, features, and how to choose the right one for you. Read more now!

Learn about the potential hazards of CNC machines, their safety features, and guidelines that will enable you to safely work with these machines, preventing accidents in the workplace. 1. Noise. 2. Chips. 3. Moving Components or Machinery. 4. Falling Heavy Objects. 5. Heat from the Cutting Process. 1. Safety or Containment Shield. 2. Video Cameras.Understanding the CNC machine buttons is integral to efficient and safe operation. The buttons covered in this guide represent the core functions necessary to effectively run a CNC machine. Of course,the specifics of these buttons can vary slightly between different models and manufacturers of CNC machines. But,with this foundation,you should .

CNC turning, CNC milling etc CNC machining work must programmed in CNC Machine operation panel to control their actions. This article explained all keys mean.Power On/Off Button: This button is used to turn the CNC machine on or off, allowing operators to start or shut down the machine safely. Start/Stop Button: The start/stop button initiates or stops the machining process. With the press of a button, the machine manuals become available to the operator right on the CNC control. This includes a programming assistant that describes the canned cycles and a G- and M-code listing. If an alarm pops up, the same button will describe the alarm and its possible causes. FUNCTION OF MDI PANEL KEYS. CNC machines need to perform many different operations as needed, many types of keys have to be used on the computer control panel to perform this type of operation.

With the manual mode, the operator of a CNC machine is allowed to press buttons, turn handwheels, and activate switches in order to attain the desired machine function. The activation of each button or switch in the manual mode has an immediate response.

To avoid surges, most CNC machines have at least two different power buttons, one for power to the control and another for power to the machine tool itself. The control panel power button must be pressed first and activates the control screen and control panel. Most CNC machines also have a jog function, allowing axis motion to be caused by a joystick or push button. Most have a button to turn the spindle on and off, as well as a rheostat to control spindle speed.

Discover the benefits of CNC control panels and pendants for CNC machining. Learn about different types, features, and how to choose the right one for you. Read more now!

cnc machine keys

Installing Dimmable Track Lighting Without House Wiring: I recently renovated my home office to go to a standing desk configuration and simultaneously change the look, which I'd had for almost 12 years. One of the items I wanted was track lighting so I could could have the flexib.

cnc machine button|cnc machine control panel