cnc machine capability study This article presents the possibilities of assessing the capability of the measurement process on CNC machine tools using a touch probe based on VDA 5 and 14253 . VETA has been specialized in fabrications of sheet metal products ranging from simple boxes, modular cabinets and enclosures, up to integrated units with IP requirements.

0 · what is machine capability

1 · manufacturing process capability

2 · machine capability examples

What they have in common is the need for a reliable manufacturing partner with .

what is machine capability

sheet metal forming english wheel

manufacturing process capability

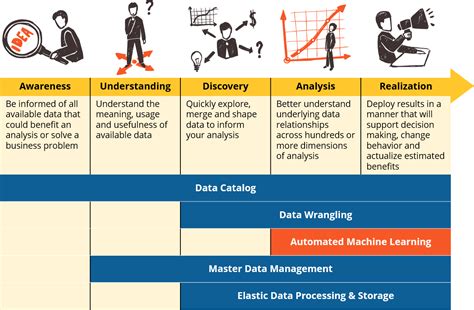

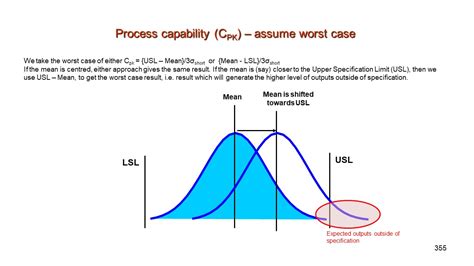

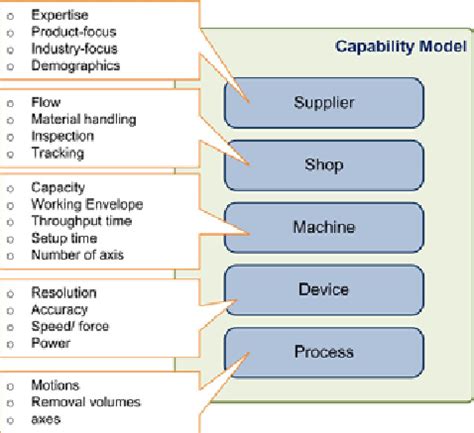

pability studies. The methodology has been designed to prove industry with a standard approach for studying processes, and enable them to produce wit. sequential order. It is divided into five .Machine capability represents the capacity of a machine to carry out a performance criteria (IT, for example). It is expressed through various indicators. The simple capability Cp with respect to a .A process capability study uses data from a sample to PREDICT the ability of a manufacturing process to produce parts conforming to specifications. This prediction enables us to "qualify" a .

Modern manufacturing industry highly demands high precision in machining to seek greater quality finishing. Therefore, a Computer Numerical Control (CNC) machine tool is equipped . This article presents the possibilities of assessing the capability of the measurement process on CNC machine tools using a touch probe based on VDA 5 and 14253 . The purpose of this study is to bring out the differences defined between these various standards, explain the method of estimating the process capability index with an .

In this paper, displacement and von Mises stress that influenced by the factors of force and heat friction on the ball screw system of the existing CNC machine were determined by performing . I'm looking for some assistance in devising a simple procedure for conducting process capability studies on the parts we machine and could use some help because I don't .

sheet metal forming products

The focus of this work is to generate a protocol for the selection of appropriate speeds and feeds for solid carbide tools in a vertical CNC milling machine. The desire is to replace generic tables . In this study, an ontology self-learning approach was developed to enrich the ontological models and knowledge base for the integration and representation of manufacturing capability information and knowledge.pability studies. The methodology has been designed to prove industry with a standard approach for studying processes, and enable them to produce wit. sequential order. It is divided into five progressive stages: 1) Process Delineation, 2) Metrology Characterization, 3) Capability Determination, 4) Optimizati.Machine capability represents the capacity of a machine to carry out a performance criteria (IT, for example). It is expressed through various indicators. The simple capability Cp with respect to a process is defined as the ratio between the tolerance .

A process capability study uses data from a sample to PREDICT the ability of a manufacturing process to produce parts conforming to specifications. This prediction enables us to "qualify" a new manufacturing process as being fit for use in production.Modern manufacturing industry highly demands high precision in machining to seek greater quality finishing. Therefore, a Computer Numerical Control (CNC) machine tool is equipped with a ball screw driving system, mainly, due to its high efficiency. This article presents the possibilities of assessing the capability of the measurement process on CNC machine tools using a touch probe based on VDA 5 and 14253-1:2017, which could enable and expand the use of CNC machine tools to inspect dimensional tolerances on workpieces.

The purpose of this study is to bring out the differences defined between these various standards, explain the method of estimating the process capability index with an example, and also provide source for the recommended permissible values as per relevant standards, to help industry partners in understanding and the calculation of the process .

In this paper, displacement and von Mises stress that influenced by the factors of force and heat friction on the ball screw system of the existing CNC machine were determined by performing the structural analysis and thermal stress analysis through Altair Hyperworks software.

I'm looking for some assistance in devising a simple procedure for conducting process capability studies on the parts we machine and could use some help because I don't have a firm grasp on how to execute a process capability study from a practical standpoint.

The focus of this work is to generate a protocol for the selection of appropriate speeds and feeds for solid carbide tools in a vertical CNC milling machine. The desire is to replace generic tables of cutting speeds and chip loads with a procedure that accommodates the entire system: material, machine, tool, cutter, and workholding.

In this study, an ontology self-learning approach was developed to enrich the ontological models and knowledge base for the integration and representation of manufacturing capability information and knowledge.pability studies. The methodology has been designed to prove industry with a standard approach for studying processes, and enable them to produce wit. sequential order. It is divided into five progressive stages: 1) Process Delineation, 2) Metrology Characterization, 3) Capability Determination, 4) Optimizati.Machine capability represents the capacity of a machine to carry out a performance criteria (IT, for example). It is expressed through various indicators. The simple capability Cp with respect to a process is defined as the ratio between the tolerance .A process capability study uses data from a sample to PREDICT the ability of a manufacturing process to produce parts conforming to specifications. This prediction enables us to "qualify" a new manufacturing process as being fit for use in production.

Modern manufacturing industry highly demands high precision in machining to seek greater quality finishing. Therefore, a Computer Numerical Control (CNC) machine tool is equipped with a ball screw driving system, mainly, due to its high efficiency.

This article presents the possibilities of assessing the capability of the measurement process on CNC machine tools using a touch probe based on VDA 5 and 14253-1:2017, which could enable and expand the use of CNC machine tools to inspect dimensional tolerances on workpieces. The purpose of this study is to bring out the differences defined between these various standards, explain the method of estimating the process capability index with an example, and also provide source for the recommended permissible values as per relevant standards, to help industry partners in understanding and the calculation of the process .In this paper, displacement and von Mises stress that influenced by the factors of force and heat friction on the ball screw system of the existing CNC machine were determined by performing the structural analysis and thermal stress analysis through Altair Hyperworks software.

I'm looking for some assistance in devising a simple procedure for conducting process capability studies on the parts we machine and could use some help because I don't have a firm grasp on how to execute a process capability study from a practical standpoint.

$8.99

cnc machine capability study|machine capability examples