sheet metal forming process and application pdf Individual chapters cover all major sheet forming processes such as blanking, bending, deep drawing, and more. Process modeling using finite element analysis is described in one chapter and discussed in all appropriate chapters. Other chapters cover sensors and die materials, which are critical for practical sheet forming applications. It seems the vanity has its own built in juntion box ( under the silver cover here) like the old vanity light. If all the connections are made within that light, not inside the drywall is this okay? The answer depends on the light. Some lights have integral boxes and therefore do not require a separate back box.

0 · sheet metal working process pdf

1 · sheet metal stamping process pdf

2 · sheet metal processes pdf

3 · sheet metal forming process pdf

4 · sheet metal forming press dies

5 · sheet metal forming by hand

6 · sheet metal bending process pdf

7 · bulk deformation vs sheet metal forming

We are pleased to introduce ourselves and offer our custom sheet metal and metal fabrication services. We offer professional, innovative, creative solutions for our client’s custom metal fabrication requirements.

steel electrical cabinets

Chapter 1 Metal Forming Processes in Manufacturing ... 1 1.1 Classification of Manufacturing Processes ... 1 1.2 Characteristics of Manufacturing Processes ... 1aerospace, and appliance industries use sheet metal forming processes that deform an initially flat sheet of metal into a final three-dimensional shape. Fundamentals and Applications of Sheet .

Sheet Metal Forming 2.810 D. Cooper !“Sheet Metal Forming” Ch. 16 Kalpakjian . describe different forming processes, when they might . %20can.pdf Deep Drawing of drinks cans . Hydro-forming – cheap tooling, no net thinning, slow(ish), high formability Individual chapters cover all major sheet forming processes such as blanking, bending, deep drawing, and more. Process modeling using finite element analysis is described in one chapter and discussed in all appropriate chapters. Other chapters cover sensors and die materials, which are critical for practical sheet forming applications.As in many other metal forming applications, process planning and design of dies for sheet forming can benefit from a combined application of knowledge based systems and process modeling. Recently, many companies are applying .UNIT 2 METAL FORMING 2.1. INTRODUCTION Metal forming can be defined as a process in which the desired size and shape are obtained through the deformation of metals plastically under the action of externally applied forces. Metal forming processes like rolling, forging, drawing etc. are gaining ground lately. It is due

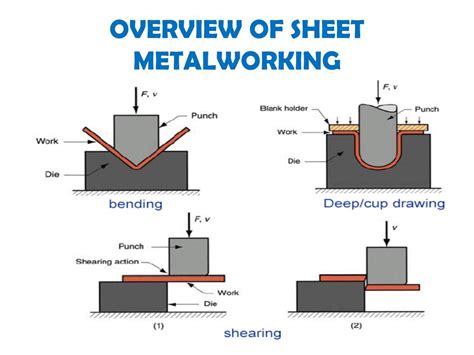

steel diamond plate utility box and cover in asphalt

Sheet Metal Forming PROCESSES ANDAPPLICATIONS Edited by Taylan Altan and A. Erman TekkayaASM International® Material. Email: [email protected] Login; Register; . OH 44073-0002 www.asminternational.org Printed in the United States of America Sheet Metal Forming—Processes and Applications T. Altan and A.E. Tekkaya, .Electrohydraulic forming • EHF is based on the ultra-high-speed deformation of metal using shockwaves in water. • The electric arc in water between two electrodes vaporizes the surrounding water, • converting electrical energy into an intense shockwave of mechanical energy. • The shockwave simultaneously transforms the metal workpiece into a visco-plastic state Bending operation in sheet metal forming has been extensively used in manufacturing technology for mass production especially in automotive industry as one of the tools for shaping into a desired . #2. Sheet metal forming. Sheet metal forming involves the application of tensile and shears forces to fabricate sheets, plates, and strips to a desired possible shape using a set of tools. The punch and die are used as tools in the fabrication process.

Compared to conventional sheet metal forming processes, advantages of RPF processes are low cost (tooling), dimensional accuracy, high flexibility, and short lead-time for tooling and part, as .%PDF-1.4 %âãÏÓ 663 0 obj > endobj 685 0 obj >/Filter/FlateDecode/ID[704E8A5A77AA90E0E45753C1AAABDACC>]/Index[663 39]/Info 662 0 R/Length 112/Prev 3172114/Root 664 .

Metal forming : fundamentals and applications by Altan, Taylan. Publication date 1983 Topics Metal-work Publisher Metals Park, OH : American Society for Metals . Pdf_module_version 0.0.20 Ppi 360 Rcs_key 24143 Republisher_date 20230211121230 Republisher_operator [email protected] . Request PDF | Development of Electromagnetic Forming Apparatus and Experimental Application to Sheet Metal Forming Processes | The Electromagnetic forming (EMF) method is one of high-velocity . Sheet Metal F orming - Bending, . • It is a highly versat ile metal forming process w hich can produce various . • It is a process in which material is shaped b y the application of . In the late 1960s, pioneer works by Keeler [] and Goodwin [] established the initial procedures for characterizing metal sheet formability based on the use of circle grid analysis (CGA) techniques, allowing for the determination of the in-plane strains on the surface of sheet metal formed parts.Later, in the early 1980s, Embury and Duncan [] introduced what they .

Download PDF - Sheet Metal Forming: Processes And Applications [PDF] [31fbjio6cl70]. This practical and comprehensive reference gives the latest developments on the design of sheet forming operations, equi.Sheet Metal Forming: Processes and Applications. Edited by Taylan Altan; Taylan Altan Search for other works by this author on: This Site. Google Scholar. A. Erman Tekkaya . Soumya Subramonian, Blanking, Sheet Metal Forming: Processes and Applications, Edited By Taylan Altan, A. Erman Tekkaya, ASM International, 2012, p 1–17, .

Surface Texture Design for Sheet Metal Forming Applications Meghshyam Shisode, Ton van den Boogaard, and Javad Hazrati . sheet metal forming. J Mater Process Technol 291:117035 3. Shisode M et al (2020) Semi-analytical contact model to determine the flattening behavior of

Numerical simulation of metal forming processes, as a component of the virtual manufacturing process, has a very important contribution to the reduction of the lead time. The nite element method is currently the most widely used numerical procedure for s- . Currently, there are two prevalent types of hybrid process chains hybridizing AM and sheet forming processes. One involves combining AM with subsequent forming operations, while the other entails applying AM to pre-formed components after sheet metal forming. Both basic hybrid process chains are feasible, but there are different limitations.Sheet-Metal Forming Processes Process Roll forming Stretch forming Drawing Stamping Rubber-pad forming Spinning Superplastic forming Peen forming Explosive forming Magnetic-pulse forming Characteristics Long parts with constant complex cross-sections; good surface finish; high production rates; high tooling costs. The application of aluminum alloys in automotive and aerospace industries has been growing significantly in the last 20 years. Due to their high specific strength, aluminum became a strong replacement for steel particularly at automotive manufacturing. However, to deform a complex panel part from aluminum is quite challenging specifically at cold forming .

Design of experiments and ANOVA have been reported to be useful in investigating the influence of process parameters in sheet metal forming (Abosaf et al., 2017;Essa, 2010).Request PDF | On Aug 1, 2018, Feifei Zhang and others published Application of Electro-hydraulic Forming (EHF) Process with Simple Dies in Sheet Metal Forming | Find, read and cite all the .In Sheet metal forming process materials undergo permanent deformation by cold forming to produce a variety of complex three dimensional shapes. The process is carried out in the plane of sheet by tensile forces with high ratio of surface area to thickness. High rate of production and formability is determined by its mechanical properties.

DOI: 10.5228/KSPP.2009.18.7.556 Corpus ID: 107581812; Study on Application of Flexible Die to Sheet Metal Forming Process @article{Heo2009StudyOA, title={Study on Application of Flexible Die to Sheet Metal Forming Process}, author={Seongchan Heo and Young Ho Seo and Tae Wan Ku and Ji-hoon Kim and Byeong-Chul Kang}, journal={Transactions of materials processing}, . Sheet Metal Forming. Another important forming process is the Sheet Forming process. The sheet-forming process works due to either the tensile force or the shear force. It can be used in Hydraulic presses to make the product from the sheets however some more steps like squeezing, bending, and so on are also included in this process.

Incremental sheet metal forming (ISMF) has demonstrated its great potential to form complex three-dimensional parts without using component-specific tools against the conventional stamping operation.

sheet metal working process pdf

sheet metal stamping process pdf

sheet metal processes pdf

How Can You Value a Vintage Metal Lunch Box? Basic principles of antique and vintage item valuations don’t necessarily apply to vintage metal lunch boxes. On the one hand, age, model, .

sheet metal forming process and application pdf|sheet metal stamping process pdf