cnc machine knowledge • Knowledge of the proper use of basic hand tools and precision measuring instruments, including calipers and micrometers. • Some manual machining experience is helpful but not required. • . The article gives an overview of sheet metal. This includes standard measurements, materials and different forming methods.

0 · getting started with cnc machines

1 · explain working of cnc machine

2 · cnc what you need toknow

3 · cnc machines for dummies

4 · cnc machine basic knowledge pdf

5 · cnc machine a beginner's guide

6 · cnc basics for beginners

7 · beginners guide to cnc

Electrical boxes, or junction boxes, are crucial components in electrical installations. Understanding the different types of electrical boxes and their specific uses is essential for anyone involved in electrical work or home improvement projects.

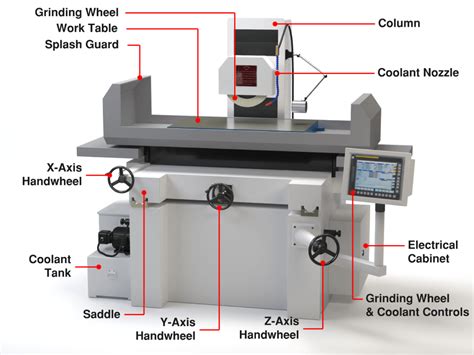

A CNC machine comprises a computerized control that operates tools and other hardware in a predetermined sequence. Depending on the task it is designed to carry out, .

What you'll learn from this video. 0:47 First, you’ll learn what CNC machining is and how CNC machines operate. 1:03 Second, we’ll show you the basic process of CNC machining in 3 steps.• Knowledge of the proper use of basic hand tools and precision measuring instruments, including calipers and micrometers. • Some manual machining experience is helpful but not required. • . Learn about the precision, automation, and versatility that make CNC machines essential for high-quality production. From the basics of how they operate to their advantages over traditional tools, discover why CNC .CNC machining is a subtractive manufacturing process that employs computerized controls and machine tools to remove layers of material from a stock piece, producing a custom-designed part. Common operations in CNC .

There are various paths to learning and, eventually, mastering CNC machining. We’ll explore how to learn CNC machining (gaining knowledge and experience), from traditional education to hands-on training. To get the best results, there is some basic knowledge you should focus your efforts on: 1. Knowing how to use a computer. A common requirement for all activities to be done with a CNC is knowing how to use a computer.

Here we’ll talk about the CNC basics for beginners covering FAQs like what machine you need to buy, what bits should you get, the definition and working of CNC system, and more. What is CNC and CNC System? CNC (Computer Numerical Control) machining is a subtractive manufacturing process that uses computerized machine tools to make a custom-designed part. A computer uses programming codes to direct machine tools to chip at (subtract) a material.

To get started in CNC, you must understand the CNC Basics. This guide will help you find top CNC tutorials suitable for beginners. We’ll guide you on the critical concepts you need to learn and the sequence to follow.

A CNC machine comprises a computerized control that operates tools and other hardware in a predetermined sequence. Depending on the task it is designed to carry out, several CNC machines are available on the market. . are defined by grasping the command knowledge and machine language basics. Programs usually begin with a ‘SETUP’ command . What you'll learn from this video. 0:47 First, you’ll learn what CNC machining is and how CNC machines operate. 1:03 Second, we’ll show you the basic process of CNC machining in 3 steps.• Knowledge of the proper use of basic hand tools and precision measuring instruments, including calipers and micrometers. • Some manual machining experience is helpful but not required. • Knowledge of Solidworks® is a pre-requisite or co -requisite for this course.

Learn about the precision, automation, and versatility that make CNC machines essential for high-quality production. From the basics of how they operate to their advantages over traditional tools, discover why CNC technology is the .CNC machining is a subtractive manufacturing process that employs computerized controls and machine tools to remove layers of material from a stock piece, producing a custom-designed part. Common operations in CNC machining include milling, turning, drilling, and grinding. There are various paths to learning and, eventually, mastering CNC machining. We’ll explore how to learn CNC machining (gaining knowledge and experience), from traditional education to hands-on training. To get the best results, there is some basic knowledge you should focus your efforts on: 1. Knowing how to use a computer. A common requirement for all activities to be done with a CNC is knowing how to use a computer.

Here we’ll talk about the CNC basics for beginners covering FAQs like what machine you need to buy, what bits should you get, the definition and working of CNC system, and more. What is CNC and CNC System? CNC (Computer Numerical Control) machining is a subtractive manufacturing process that uses computerized machine tools to make a custom-designed part. A computer uses programming codes to direct machine tools to chip at (subtract) a material. To get started in CNC, you must understand the CNC Basics. This guide will help you find top CNC tutorials suitable for beginners. We’ll guide you on the critical concepts you need to learn and the sequence to follow. A CNC machine comprises a computerized control that operates tools and other hardware in a predetermined sequence. Depending on the task it is designed to carry out, several CNC machines are available on the market. . are defined by grasping the command knowledge and machine language basics. Programs usually begin with a ‘SETUP’ command .

What you'll learn from this video. 0:47 First, you’ll learn what CNC machining is and how CNC machines operate. 1:03 Second, we’ll show you the basic process of CNC machining in 3 steps.• Knowledge of the proper use of basic hand tools and precision measuring instruments, including calipers and micrometers. • Some manual machining experience is helpful but not required. • Knowledge of Solidworks® is a pre-requisite or co -requisite for this course.

Learn about the precision, automation, and versatility that make CNC machines essential for high-quality production. From the basics of how they operate to their advantages over traditional tools, discover why CNC technology is the .CNC machining is a subtractive manufacturing process that employs computerized controls and machine tools to remove layers of material from a stock piece, producing a custom-designed part. Common operations in CNC machining include milling, turning, drilling, and grinding. There are various paths to learning and, eventually, mastering CNC machining. We’ll explore how to learn CNC machining (gaining knowledge and experience), from traditional education to hands-on training. To get the best results, there is some basic knowledge you should focus your efforts on: 1. Knowing how to use a computer. A common requirement for all activities to be done with a CNC is knowing how to use a computer.

getting started with cnc machines

how to replace ram distribution box

A Sheetmetal Mechanic sets up and operates machines such as drill presses, punch presses, saws, shears, bending rolls, brakes, grinders, and numerical control equipment to shape and alter sheetmetal according to specifications. Follows blueprints, rough sketches, or engineer drawings to shape metal accurately.

cnc machine knowledge|cnc machine a beginner's guide