offset in cnc machine The key elements of a CNC machine are described as the input device, machine control unit, machine tool, driving system, feedback devices, and display unit. The document also covers the basic programming and operation of CNC machines using G and M codes to control axes movement, feed rates, spindle speeds, tool changes, and other functions. We’ll explore the fundamentals of common metal fabrication processes such as forging, casting, extrusion, machining, stamping and punching operations.

0 · what is work offset

1 · what is wear offset

2 · what is tool length offset

3 · tool offset in cnc milling

4 · offset turning on cnc lathe

5 · offset meaning in cnc programming

6 · fixture offset cnc

7 · cnc tool offsets explained

After devices have been fabricated in the silicon substrate, connections must be made to link the circuits together. This process is called metallization. Metal layers are deposited on the wafer .

Learn all about CNC offsets and how they are used in CNC machining. Includes info on how to use them and what to watch out for.

When it comes to programming CNC machines, you’d probably want to know that there are a variety of CNC offsets a user can utilize in order to maximize their compensation. Think of it as an electronic calculator—you’d . To start using work offsets, first, ensure you have a basic understanding of CNC machine operations. Work offsets allow you to establish reference points for your workpiece. Begin by referencing your CNC machine’s . How to measure TLO for CNC Milling the easy way!In this video we'll use angle plates, vernier height gauge and the Heidenhain TNC320 Control to set up a Cent.

The key elements of a CNC machine are described as the input device, machine control unit, machine tool, driving system, feedback devices, and display unit. The document also covers the basic programming and operation of CNC machines using G and M codes to control axes movement, feed rates, spindle speeds, tool changes, and other functions. Suppose that the first ten .001mm offset adjustments are required every 20 parts, the second group of ten offset adjustments is required every 19 parts, the third group of ten offset adjustments is required every 18 parts, etc. It would be easy to make a macro that decreased the increment periodically. Hello Viewers, In this video you will learn How to take offset in CNC machine. This is CNC programming Part 5.Geometric Offset, Work Offset enables CNC machi. The D offset value is a number stored in the CNC machine controls that tells the CNC the size of the cutting tool. Once the machine knows the size of the cutter it can adjust how it runs the program based on that size.

The 5-axis machine requires nine offset param eters instead of six for the 4-axis machine tool. Table 2 gives the recomme nded Global Offsets based on the part measurement Tool radius compensation allows the CNC machine to adjust the toolpath based on the actual size of the cutting tool used. With G41 (left-hand side) or G42 (right-hand side) active, the machine offsets the programmed path inward or outward by half of the tool’s diameter, resulting in accurate cuts. The control software for the CNC machine sets the cutter offset, which will differ depending on the cutting tool and procedure types. Source: YouTube. There are two common types of cutter offsets: Cutter Radius Compensation (CRC): This offset accounts for the radius of the cutting tool – typically used in CNC milling.

We use the tool length to offset the spindle nose back by the length of the tool. This ensures that the tool’s tip drives to this new point instead of to the spindle nose. By letting the machinist set a z-axis datum for each part, the tool length offset enables the CNC machine to compensate for many tools of different lengths.Positive Tool Offsets (gage line tool length offsets) In the case of Positive Tool Offsets, the offset represents the Length of the tool measured as a distance from the Gauge Line of the spindle (typically spindle nose) to the tip of the tool. The longer the tool, the larger your Tool Length offset will be.. In such a case, Part Z Work Offset will represent the distance between the same Gage . What is CNC machine offset? CNC machine offset refers to the distance between the tool and the workpiece. It is an essential parameter that the CNC machine operator or programmer must adjust to ensure that the tool cuts the workpiece at the correct location. CNC machine offset includes several types such as tool length offset, tool radius . However when I watch videos of setting tool offsets for a cnc milling machine they all show how to set the tool offsets on finish (sides/top) of parts. My question is how to allow for Roughing? If you put a part that is from stock material in a machine and touch off your tools how will you know the finish surface for your finishing tools .

Results, vmc programming examples , cnc programming examples, admit card , new job vacancy , vmc programming, machine drawing, cnc , vmc ,cutting tool

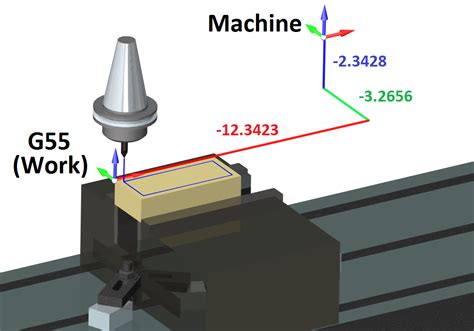

CNC programming is essential for accuracy and efficiency in machining operations within the manufacturing industry. This article explains what G10 CNC code does, a command to set tool offsets and manage coordinate . As you know, Fanuc-controlled machining centers come with at least six fixture offsets, invoked in a program by G54 through G59 respectively. When the machine executes a G54, for example, it knows to look at the registers in fixture offset number one to find the program zero assignment values for the current coordinate system. (G59, of course, tells the machine .CNC machine offsets are compensation values applied to tool positioning to account for variations in tool dimensions, machine alignment, and part geometry. By correctly setting the offsets, machinists can achieve precise machining, eliminate .

what is work offset

1 फरवरी से CNC TRAINING का बैच स्टार्ट हो रहा है |Institution name:- Techno CAD - CAD / CAM / Practical CNC Training CenterShed No.63, Barcelona . Every practice of compensation has to do with offsets (especially in regards to CNC offsets)! One can consider CNC offsets as memories on an electronic calculator. If your calculator has memory, you can store a constant value to each memory for use throughout a calculation. . With most CNC machine tools, it is necessary to have at least one .

2. Consistency: Offset allows CNC machines to produce consistent results even when the tools wear out or need to be replaced. By adjusting the tool length and diameter offsets, the machine can maintain the desired cutting dimensions consistently. 3. Efficiency: With proper offset adjustments, CNC machines can reduce the need for manual .

Fanuc Macro System Variable lists parametric programming Purpose Variable number Contents Series Variable number #1000?#1015 #1032 #1100?#1115 #1132 #1133 #2001?#2064 #10001-#10999 #11001-#11999 #2001-#2200 (Offset No. 1?64) Geometry offset value (Offset No. 1?49) Wear offset value (Offset No. 1?99) Geometry offset value (Offset No. 1?99) #2201-#2400 . wear offset का यूज करना सीखें | how to take wear offset in cnc machine | wear offset | cnc offsetfacebook Page = https://www.facebook.com . Hello Friends,In this video we will discus about offset of cnc machine . What is offset of cnc machine .Types of offset in cnc machine .How to take offset in.

2 Global Offset System 2.1 Why Global Offset A CNC machine tool is designed with a table to mount a fixture and locate a part on the fixture for machining. The fixture is aligned to the table and the table is installed on the CNC machine. Due to imperfections in the machine and fixture manufacturing, the actual table center and fixture center . Onefinity CNC Forum Extended work offsets. Machines (Elite Series) MG2 (Bob ) October 29, 2024, 1:54pm 1. Has anyone used the extended work offsets G54.1P1 to P100 on there machine. Thank You Bob. John October 29, 2024, 4:11pm 2. G54. Extended work offsets and cutter comp are still in beta. Wish I had known this beforehand because it’s the . Tool offset is the relative displacement applied to the coordinate axes of a machine tool during all or a specified part of a machining program. . In the CNC machine tool-turning process, using the tool compensation function can be programmed according to the size of the workpiece profile.

what is wear offset

metal wire air conditioner line protector outside house

metal wire stretched fabric

what is tool length offset

His 1099-R shows a taxable distribution in box 1 and 2 for fed taxes. However, box 16 (state distribution) does not show an amount. Does that mean this pension/retirement income was not taxable at state level?

offset in cnc machine|offset turning on cnc lathe