cnc machining teflon Now let’s explore the primary Teflon machining methods. CNC Machining of Teflon. Computer Numerical Control (CNC) machining is a widely used technique in the manufacturing industry, including CNC turning and CNC . $1.38

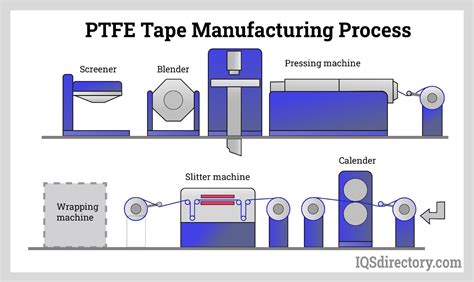

0 · teflon tape manufacturing process

1 · teflon molding process

2 · teflon injection molding

3 · teflon cutting speed chart

4 · teflon cutting block

5 · how to use liquid ptfe

6 · how to cut teflon sheet

7 · how to cut teflon

With National Electrical Manufacturers Association (NEMA) rated and Underwriter Laboratories (UL) Listed cabinets from APX, you can ensure optimal protection against harsh external .

CNC machining material PTFE plastic overview (what is PTFE or Teflon, characteristics, mechanical properties, uses and applications) and . This article explores the ins and outs of Teflon processing: its material properties, processing advantages, common applications, and more. CNC machining PTFE is ideal for manufacturing parts for different applications .

Precision Plastic and Composite CNC Machining since 1970. ©2024 Upland Fab - 1445 W Brooks Street, Unit L, Ontario, California 91762 - Phone: (909) 986-6565. Request Quote. Now let’s explore the primary Teflon machining methods. CNC Machining of Teflon. Computer Numerical Control (CNC) machining is a widely used technique in the manufacturing industry, including CNC turning and CNC .PTFE-Teflon CNC machining is widely applied for common use in different industries through the manufacturing of Teflon machined parts or components. What Is PTFE Plastic or Teflon? PTFE, or polytetrafluoroethylene, is a .

When CNC machining Teflon, very sharp tools combined with water-soluble coolants such as pressurized air and spray mists work well to produce the best surface finishes and tolerances. Non-aromatic coolants are also preferable. Another key consideration when machining Teflon is deburring. Because PTFE is so soft, even fine, sharp cutting tools . Mastering the Art of Teflon Machining: A Complete Guide to Teflon Plastic Sheet Fabrication. The Teflon plastic sheet is widely recognized for its chemical resistance, low friction, and heat-resistant properties, making it indispensable for various industrial applications.In this post, I’ll dive into the essentials of machining PTFE materials—covering the Teflon machining .Read more about Teflon in CNC machining here. PTFE, commonly known as Teflon, is commonly used as insulator because it resists high temperatures. Try the First-Ever Auto DFM for Injection Molding Learn More.

Teflon-coated cookware that is manufactured is rare. The solid state of Teflon, on the other hand, is amenable to CNC machining. Teflon can be machined into a variety of industrial components, including gears, bushings, fittings, and valves. In industries like as health, food processing, science, and aerospace, CNC-machined PTFE products include:PTFE (Teflon) in CNC Machining. Polytetrafluoroethylene (PTFE), known commercially as Teflon, stands out due to its remarkable properties, making it a highly sought-after material in the CNC machining industry. PTFE’s low friction coefficient ensures smooth operation and reduces wear and tear, vital for moving parts. .Polytetrafluoroethylene (PTFE), commonly known by its trade name Teflon, is a versatile and highly desirable material for CNC machining due to its unique properties. It is a type of fluoropolymer and is best known for its non-stick and low-friction properties. This makes it an excellent choice for applications that require a low coefficient of .

Teflon turning and shaping advancements through CNC machining provide amounts of precision, especially suitable for aerospace productions that require the most accuracy than any other type of industrial production. Teflon manufacturer uses advanced CNC programming to machine Teflon parts that meet the strict requirements of the aerospace industry..

teflon tape manufacturing process

Summary of Main Points: Teflon plastic sheet properties: Discover the unique features that make Teflon essential, including chemical resistance and thermal stability.; PTFE applications: How PTFE sheets are used in industries like aerospace, electronics, and food processing.; Teflon machining process: Best practices for fabricating custom PTFE parts and .3Q MACHINING has a reputation for machining quality parts from Teflon. We can machine intricate parts on our CNC Turning Service. PTFE (more commonly known as Teflon) is an extremely resilient plastic, ideal for screw machine parts that require high impact strength and durability. It has excellent resistance to frictional wear, weathering,.CNC (Computer Numerical Control) machining is a superior method for manufacturing Teflon parts due to several key advantages it offers over traditional machining techniques: Precision and Accuracy : CNC machines are capable of extremely precise and accurate movements, allowing for tight tolerances and intricate geometries in Teflon parts. In the intricate machining industry, PTFE, often recognized by its trade name Teflon, emerges as a paramount material. With its unique challenges and rewards, PTFE machining has become a cornerstone in producing high-quality components. Whether through CNC machining, CNC turning, or even specialized CNC turn-mill machining, the production of .

Cox Manufacturing has a reputation for machining quality parts & high volume swiss screw machining from Teflon. We can machine intricate parts on our CNC Swiss machines and CNC turning centers.. PTFE (more commonly known as Teflon) is an extremely resilient plastic, ideal for screw machine parts that require high impact strength and durability. It has excellent .CNC plastic machining is a vital manufacturing process that leverages the unique properties of various plastics and the advanced capabilities of CNC machining to produce highly accurate and complex components across numerous industries. With the ability to create custom parts and balance cost and performance, CNC plastic machining offers a .

Plastic CNC machining offers greater dimensional accuracy, and 5-axis CNC milling machines can help you tackle the most difficult manufacturing challenges by providing high precision machining of more complex parts. Applications of .

What are the Different Machining Processes for Teflon/PTFE? CNC Milling: This is a cornerstone in our arsenal for machining Teflon. CNC milling allows for intricate designs and precise tolerances. However, milling Teflon is like conducting a delicate symphony requiring the right tools, speeds, and feeds. I have a job coming up where I need to turn these smallish teflon bushings. The bar is 7/8 diameter and the length is about 1" long. I've never ran Teflon before in our lathe and wanted to get some suggestions from people who have experience turning it. What kind of finish cuts do you need and.As the leading manufacturer of CNC machining Teflon parts for over 25 years, Worthy Hardware is well equipped with 35 sets CNC Machines, including 3 sets 5 axes,4 sets 3 axes, 12 sets turning and milling compound.These machines could allow us to make prototypes,small-batch and mass production parts for Teflon materials. LDPE is a tough but flexible CNC machining plastic known for its low-temperature flexibility and corrosion resistance. It’s easy to weld and heat seal and offers good chemical resistance. LDPE is primarily used for orthotics and prosthetics. However, LDPE shouldn’t be used for applications in which stiffness, high structural strength, and .

Nylon is a high purity semi-crystalline CNC plastic machining material known for its excellent thermal, mechanical, and chemical resistance. CNC machining nylon is easy as the material offers tight tolerance due to its physical properties and dimensional stability. It also behaves like a metal, evident in the popular saying, “machining nylon is like machining brass.”APT is specialized in PTFE CNC machining and compression molding. LogIn; Cart (0) Applied Plastics Technologies 45 Broadcommon Road, PO Box 45, Bristol, RI 02809. menu (800) 752-7082. . Teflon™ PTFE CNC Machining APT's skilled machinists have the knowledge & experience required to custom machine precision Teflon™ PTFE .CNC Machining Teflon/PTFE: Precision, Advantages, and Expertise Introduction: What is Teflon? Teflon, often recognized by its chemical name, polytetrafluoroethylene (PTFE), is a synthetic fluoropolymer with a range of unique characteristics. Known best for its non-stick properties, Teflon is much more than just a pan coating. .CNC (Computer Numerical Control) machining of PTFE, commonly known as Teflon, represents a pinnacle of precision in the fabrication of polymer components. PTFE, with its outstanding chemical resistance, low friction, and high-temperature tolerance, is a material of choice in various industries, including aerospace, medical, and chemical processing.

Choosing the right parameters can make all the difference when it comes to getting consistent quality results with teflon (PTFE) machining projects. If done correctly, it'll save you time, money, and frustration in the long run! Advantages of Machining Teflon. By machining Teflon, you're investing in a material that's durable and long-lasting.CNC Machining Teflon on the DN Solutions Puma 2600SY II Lathe. Using a MultiAxis Toolpath from Mastercam.Help support FREE industrial education by purchasing.

teflon molding process

Choose from our selection of metal U-channels, including low-carbon steel U-channels, architectural 6063 aluminum U-channels, and more. In stock and ready to ship.

cnc machining teflon|how to use liquid ptfe