tracking scrap in sheet metal fabrication In this article, we'll explore some strategies and how to align technology like ERP, MRP, and MES to elevate how sheet metal fabrication work gets done right, and profitably. Design for Manufacturing (DFM) Approach. Effective cost reduction . In this extensive guide, we have covered the fundamentals of CNC turning inserts, explored the different types, materials, and coatings available, and provided valuable tips for selecting and using the right insert for optimal efficiency.

0 · Steel & Metal Fabrication Inventory Solutions

1 · Optimizing Sheet Metal Fabrication: Guide to Throughput

2 · Material utilization in metal fabrication

3 · How Good Design and Metal Fabrication Software

4 · Effective Inventory Management for Sheet Metal

5 · Automation for remnant management in laser cutting

6 · A ROADMAP FOR SUCCESSFUL SHEET METAL

7 · 5 Ways to Reduce Scrap and Rework in Your

8 · 12 metrics for metal fabrication success

Are old ammo boxes worth anything? Yes, old ammo boxes can hold value among collectors and enthusiasts. The worth of these boxes depends on factors such as rarity, condition, historical significance, and demand.

Software has made tracking remnants in sheet metal cutting easier, but operators still manually remove and store them. Now, however, shops have automated options.Inventory Tracking Systems: Invest in modern inventory tracking systems that offer real-time visibility into your inventory levels. These systems can help you monitor stock movements, identify slow-moving items, and trigger reorder . The first step in conducting throughput analysis is to collect relevant data, including production records, cycle times, yield rates, and scrap rates. This data can be .

In this article, we'll explore some strategies and how to align technology like ERP, MRP, and MES to elevate how sheet metal fabrication work gets done right, and profitably. Design for Manufacturing (DFM) Approach. Effective cost reduction .Anupreethi M. Effective management of metal fabrication inventory can determine the success or failure of businesses. Balancing inventory levels is crucial as excessive stock ties up working capital, while insufficient inventory disrupts . Scrap and rework in manufacturing are generally seen as an unavoidable and expensive part of doing business. But with careful planning, manufacturers can minimize the bottom-line impacts of materials costs and .

Driven by reliable data, connected solutions for sheet-metal fabrication optimise materials, time, and labour. Striving for greater efficiency has historically meant churning out parts at breakneck speed, crossing our fingers . Strategic nesting is a balancing act sheet metal and plate fabrication. You want optimal material yield and cutting process stability, but you also need to consider downstream operations. . It also helps to understand .

Your teams can see the same information across our multiple project views, such as list, calendar and sheet views or kanban board to visually track your workflow. Track Progress and Performace With Real-Time .What Are Best Practices for ITAR Compliance for Metal Fabricators? It is EVS’s belief that metal fabrication companies that certify under current ISO 9001 standards will likely have an easier time developing best practices for ITAR .Sheet metal fabricators also have these same choices. The most significant choice involves coatings such as plating or powder coating. In many cases, the cost of the equipment is simply too much given the small amount of customer requirements for the coating. In other cases, the EPA requirements or the

Steel & Metal Fabrication Inventory Solutions

Here are nine sheet metal fabrication trends to watch for in 2021. 1. Industry Outlook. The global sheet metal fabrication market was valued at .980B in 2020 and is expected to grow at a CAGR of 3.1%, reaching .740B by 2027. The “market” in this case covers all different forms of fabrication, including metal cutting, machining .We use cookies and other tracking technologies, including session replay tools, to learn how you use the site in real-time, track and tailor your online experience, serve targeted marketing, and improve the website. . Sheet Scrap Calculator We offer custom cut-to-size sheets in many products, gauges and finishes. . Metal Fabrication; Metal . Material utilization in metal fabrication . and material tracking. You spend time locating the best full or partial sheet for the job, laying out a nest with acceptable utilization, and performing secondary cleanup not typically required with automated cutting. Even at this early stage, though, you begin laying the foundation for better . Sheet Metal Duct Fabrication Software. Sheet metal duct fabrication software is a significant advancement within the HVAC industry. The software is innovative and has become a game-changer for HVAC professionals because it offers specialized tools to streamline the design, fabrication, and installation of ductwork systems.

Quality control in sheet metal fabrication detailing entails several challenges that can significantly impact the final product’s integrity and client satisfaction.Here are key challenges and their implications: Balancing Cost and Quality: Achieving the right balance between cost and quality is crucial. High-quality standards often increase costs, while cost-cutting can .The Fabrication Station (or "Fabristation") is an interactive computer terminal and attached pneumatic tubing in the far corner of the garage backrooms. It allows The Driver to purchase item blueprints and car and garage upgrades in exchange for Anchor Energy and some incidental raw materials. Purchased blueprints and upgrades are deposited immediately next to the terminal .

Our 60,000-square-foot state-of-the-art manufacturing facility, quality equipment and experienced metal fabricators enable us to handle even the most complex sheet metal fabrication project. Whether you need a prototype or a large-scale production run, we have the ability and technology to deliver the results you need.

The LEAN Sheet Metal Storage Racks keep raw metal material easily accessible, protected and secure and with a manual cartridge system, will immediately free up floor space, increase efficiency, improve safety and help you create a leaner manufacturing facility. Get A Quote. They define the permissible limits of variation in a physical dimension which is a very crucial quality metric in sheet metal fabrication drawings. The International Organization for Standardization (ISO) provides globally recognized standards in sheet metal fabrication through ISO 2768-1:1989. It outlines general tolerances for various aspects . Sheet Metal Cutting Processes Sheet metal is a rolled metal object with a large surface area to volume ratio, usually 6 mm or less thick. It varies from plate metal, which is thicker. Sheet metal cutting is a vital operation in the fabrication industry, with many processes used to meet varied needs and material types.

Introduction. Sheet metal manufacturing is a fundamental part of modern industry, transforming raw metal into essential components for a wide range of products, from consumer electronics to heavy machinery. This . This article focuses on the importance of sustainable practices in sheet metal working, highlighting strategies to reduce waste generation, optimize energy consumption, promote recycling, and embrace green technologies. By .

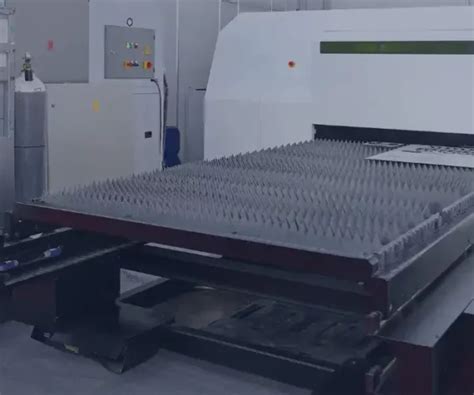

OBJECTIVE • To Increase the utilization of resource by availing the suitable scrap sheets for Punching operation. • To develop the Scrap tracking and management system to track the scrap sheets formed in the punching . Software automation in a high-mix sheet metal shop Manufacturing software, buttressed by AI, could change metal fabrication as we know it . Slim margins are usually the name of the game in the highly competitive metal fabrication industry, and there is enormous competitive pressure to eliminate waste. . nesting parts, tracking down raw .

Optimizing Sheet Metal Fabrication: Guide to Throughput

Consider a pallet of sheet metal skeletons fresh off a laser cutting machine. These skeletons must undergo a number of value-adding steps before a mill will buy them. They need to be segregated by type and cut down to a mill-acceptable size, such as a 3- by 3-foot section. Driven by reliable data, connected solutions for sheet-metal fabrication optimise materials, time, and labour Striving for greater efficiency has historically meant churning out parts at breakneck speed, crossing our fingers as we test prototypes destined for the scrap heap, and dealing with quality issues only after components are finished. While this approach paved the .Most metal fabricators have limited space, and therefore, service centers will store the material. Fabricators often do not have to carry the items until it is delivered to the shop. RealSteel™ can provide accurate and automated tracking of both material and data to ensure successful and cost-effective deliveries. From precision metal stamping and welding to custom sheet metal fabrication and metal assembly services, Prince Manufacturing possesses the expertise and resources to tackle even the most complex government and defense projects with precision and efficiency. Moreover, its adherence to strict quality control measures and regulatory compliance .

Implementing waste minimization techniques such as nesting and offcut optimization helps maximize material utilization in sheet metal fabrication. Nesting software arranges parts on metal sheets in a way that minimizes scrap, while offcut optimization identifies the best use for leftover materials, reducing waste. Estimating basics and quoting jobs in custom metal fabrication Job costing in today’s changing economy and competitive manufacturing landscape . Static spreadsheets used for estimating and tracking costs need to be replaced by dynamic data management, such as enterprise resource planning systems that incorporate historical, tribal knowledge . Precision sheet metal fabricators deal with an extraordinary number of jobs. The amount of data to manage can be immense. . The MES is tracking manual operations like welding and automated processes like laser cutting, as well as all the exceptions and problems, like machine breakdowns and excessive scrap.

When possible, unusable scrap and aging, unsold finished goods should be sold—even at a loss—to a third party. To minimize such losses, companies can be creative, for example, reworking inventory into alternative, more saleable forms and changing an item’s finishing or size to make it viable for another customer. Construction Manufacturing, specifically mechanical and sheet-metal fabrication, keeps buildings running and daily life enjoyable. The bottom line is that fabrication and fabrication shops are essential in modern construction practices. Learn ten ways that you – Our much appreciated and valued Fabricator, can improve your Fabrication Shop.

5 square electrical box 1 1 4 ko

50 pair telephone junction box price

The 7 most common types of enclosures are: 1. Open Drip Proof (ODP) Allows air to circulate through the windings for cooling, but prevent drops of liquid from falling into motor within a 15 degree angle from vertical. Typically used for indoor applications in relatively clean, dry locations. 2. Totally Enclosed Fan Cooled (TEFC)

tracking scrap in sheet metal fabrication|5 Ways to Reduce Scrap and Rework in Your