24x14 sheet metal radius 90 Minimum Bend Radii: The minimum bend radius data shown in these charts is measured to the inside of the bend. The bend radii listed are standard minimum if manufacturing for aircraft and . The EBJ Series is a submersible conduit-mounted junction box for underwater electrical connections. Ideally used for lights with 16/3 cable. Looking for help with your project?

0 · standard sheet metal bend radius

1 · stainless steel bend radius

2 · sheet metal flange radius

3 · protocase sheet metal bend radius

4 · aluminum bend radius table

5 · aluminum bend radius chart

High-quality column covers from United Best Sheet Metal are perfect for adding a unique look to your building projects. We offer our column covers in a wide range of options and colors, so you can customize them to match your needs.

standard sheet metal bend radius

large cnc turning services suppliers

stainless steel bend radius

Use Xometry reference tables for sheet and aluminium to find out which bend radius is the most suitable for your sheet metal projectsMinimum Bend Radii: The minimum bend radius data shown in these charts is measured to the inside of the bend. The bend radii listed are standard minimum if manufacturing for aircraft and .Use SendCutSend’s bending calculator to input your desired material and the units of measurement for your design to get the calculated bend allowance and bend deduction for .

The sheet metal bending radius is a critical value in sheet metal drawing that can be difficult to determine during the actual processing. This radius is dependent on the material .90-degree cold forming of sheet The radii listed are the minimum recommended for bending sheets and plates without fracturing in a standard press brake with air bend dies. Your best bet when designing formed parts is to use the industry standard bend radius of 0.030”. This measurement ensures consistent, high-quality parts with solid structural .

Navigate your projects seamlessly with our comprehensive 90° Bend Radius Chart. Accurate, reliable, and easy to understand - a must-have tool for professionals! Use Xometry reference tables for sheet and aluminium to find out which bend radius is the most suitable for your sheet metal projects

large electrical exterior enclosures aluminum

It is most economical to use a single bend radius throughout the design, but if necessary, you can utilize multiple radii. Use this document to choose values that are both manufacturable and meet your needs.Minimum Bend Radii: The minimum bend radius data shown in these charts is measured to the inside of the bend. The bend radii listed are standard minimum if manufacturing for aircraft and aerospace applications.Use SendCutSend’s bending calculator to input your desired material and the units of measurement for your design to get the calculated bend allowance and bend deduction for your part before sending it to our lasers. The calculator also allows you to input flanges. Select material type, thickness, and desired units. Enter your base length. The sheet metal bending radius is a critical value in sheet metal drawing that can be difficult to determine during the actual processing. This radius is dependent on the material thickness, the pressure of the press brake machine, and the width of .

90-degree cold forming of sheet The radii listed are the minimum recommended for bending sheets and plates without fracturing in a standard press brake with air bend dies. Your best bet when designing formed parts is to use the industry standard bend radius of 0.030”. This measurement ensures consistent, high-quality parts with solid structural integrity. We use 0.030" for all material thicknesses up to 0.125" (⅛") and increase the bend radius for thicker materials. Navigate your projects seamlessly with our comprehensive 90° Bend Radius Chart. Accurate, reliable, and easy to understand - a must-have tool for professionals!

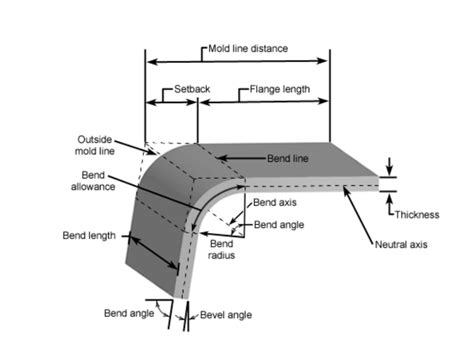

K-factor, bend allowance/deduction, and outside setbacks all affect sheet metal design. Learn about them to avoid issues during your design process.

Sheet metal bend radius is an essential factor to consider during metal forming processes like air bending or metal bending with a press brake. The bend radius refers to the curvature of a bend and is determined by the material type, thickness, and bend angle.

Use Xometry reference tables for sheet and aluminium to find out which bend radius is the most suitable for your sheet metal projects

It is most economical to use a single bend radius throughout the design, but if necessary, you can utilize multiple radii. Use this document to choose values that are both manufacturable and meet your needs.

Minimum Bend Radii: The minimum bend radius data shown in these charts is measured to the inside of the bend. The bend radii listed are standard minimum if manufacturing for aircraft and aerospace applications.Use SendCutSend’s bending calculator to input your desired material and the units of measurement for your design to get the calculated bend allowance and bend deduction for your part before sending it to our lasers. The calculator also allows you to input flanges. Select material type, thickness, and desired units. Enter your base length. The sheet metal bending radius is a critical value in sheet metal drawing that can be difficult to determine during the actual processing. This radius is dependent on the material thickness, the pressure of the press brake machine, and the width of .90-degree cold forming of sheet The radii listed are the minimum recommended for bending sheets and plates without fracturing in a standard press brake with air bend dies.

Your best bet when designing formed parts is to use the industry standard bend radius of 0.030”. This measurement ensures consistent, high-quality parts with solid structural integrity. We use 0.030" for all material thicknesses up to 0.125" (⅛") and increase the bend radius for thicker materials.

Navigate your projects seamlessly with our comprehensive 90° Bend Radius Chart. Accurate, reliable, and easy to understand - a must-have tool for professionals!K-factor, bend allowance/deduction, and outside setbacks all affect sheet metal design. Learn about them to avoid issues during your design process.

Measures 20-5/8 by 13-3/4" high by 9" deep. No Key. Box has been repainted. Vintage condition. Normal dents and dings. Paint loss. Felt is rough. Drawers work as they .

24x14 sheet metal radius 90|sheet metal flange radius