what is the best welding rod for sheet metal Once you’ve chosen your welding rod diameter, use the stick welding rod chart at the top of the page to find the amperage range for that specific electrode. The amperage that you . See more Order Waterloo Portable Tool Box, Steel, Black, MP-2012BK at Zoro.com. Great prices & free shipping on orders over $50 when you sign in or sign up for an account.

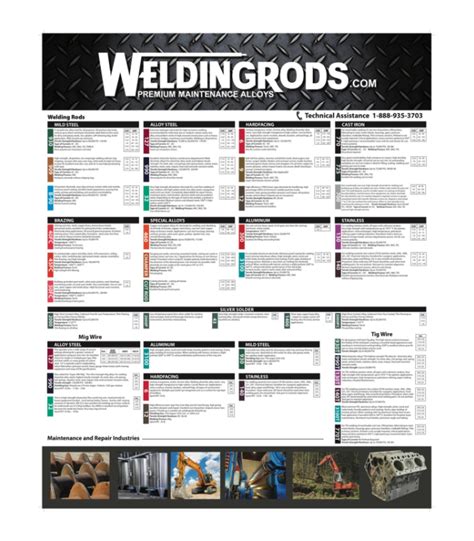

0 · welding rod uses chart

1 · welding rod types chart

2 · welding rod differences chart

3 · welding rod comparison chart

4 · most commonly used welding rods

5 · most common welding rod size

6 · best welding rod for overhead

7 · best all purpose welding rod

$35.99

The primary factor when choosing the size of a welding rod is the thickness of the base metal that’s going to be welded. The welding rod should be thinner than the base metal, but not thinner than half of the base metal. The thicker the base metal, the larger the welding rod diameter and the amperage. The . See moreThe most popular welding rods for hobbyists are 3/32” rods. 1/8” and 5/32” are also very common. Larger diameter welding rods are only . See more

Once you’ve chosen your welding rod diameter, use the stick welding rod chart at the top of the page to find the amperage range for that specific electrode. The amperage that you . See more

Setting the wrong amperage can cause weld defects and trouble starting the arc. If you’re not getting the results you want but aren’t sure if you’ve set the amperage too low or too high then look out for these indicators. Different manufacturers can have slightly different . See more Still, it’s possible to weld thin sheet metal using the MIG (GMAW), TIG (GTAW), and stick (SMAW) processes. But MIG and TIG provide the best results. This article will teach you how to weld thin gauge metal using each arc .Last Updated on: June 11, 2022. The calculator below pinpoints exactly which electrode you need for the metal you are welding. You will also get the required polarity, position, and other related .

Compare the differences between 6010, 6011, 6013, 7018 & 7024 welding rods and learn how to choose the right one for your job!

When welding sheet metal, learn why MIG, pulsed MIG, TIG and pulsed TIG are the ideal process choices for getting the best results.

E6013 is a High Titania Potassium rod designed for welding sheet metal. It can be run on AC, DCEP and DCEN. The rod has low penetration, dense slag, soft and stable arc, while it can be used in all positions, it needs clean base metal to . Stick welding of sheet metal shall be carried out using AWS A5.1/A5.1M E6013 (CWB/CSA W48-06 E4313) type electrode of diameter 5/64 inch or 2.0 mm. E6013 types electrode offer very good arc stability, easy-to .

Selecting the appropriate welding rod is crucial, as it influences the weld’s quality, ease of application, and final appearance. This article explores the characteristics and benefits ..196.86.69

welding rod uses chart

welding rod types chart

5.58.907.215.73

Which rods should I use to weld mild steel sheet metal? The sizes I'll mostly be welding will be about 1/8-1/4 and occasionally about 3/4 of an inch. using the SA200, I'm told it .

Of these methods, the best one for welding thin metals is MIG welding. This is the most common type of welding that people in manufacturing use for welding sheet metals, which are thin pieces of metal. You can also .The best rod to be used depends on a couple of factors like the thickness of the base metal being used. If you are using a new 1/8” material, then you should probably go for 3/32” 6013 rods. If you are using a new 1/8” material, then you .

Best Stick welding rods. The AWS classification recognizes more than 100 different Shielded metal arc welding rods that have different properties that fit different uses. However, as a beginner, hobbyist, or DIY lover, you are .

Stick welding of SMAW welding for Thin Sheet Metal Welding. Material as thin as 16 gauge, approximately 1/16 in. (2 mm) thick up to several feet thick, can be Stick welded. Stick welding is one of the options to perform . Which rods should I use to weld mild steel sheet metal? The sizes I'll mostly be welding will be about 1/8-1/4 and occasionally about 3/4 of an inch. using the SA200, I'm told it can handle it.. welds gotta finish up presentable lol I know each rod welds differently. Have a minute to read a bit more in depth? Hi there. I am trying to figure out what the best grade of sheet steel would be to repair my woodsove and the best rod to use in order to take the abuse of heating? thanks . General Welding Questions; Best rod and sheet steel for a wood stove; . I might look at having my metal supplier roll heavier sheet, say 3/16", or have a friend I know with a .

The process for using MIG welding is relatively simple: the welder applies an electric arc between a consumable electrode wire and the thin sheet metal, creating a strong bond between the two pieces. Tungsten electrodes. Tungsten electrodes are often used with MIG welding for improved weld strength and esthetic appeal. They provide greater penetration into the metals being . Welding rods, also called welding electrodes, are mineral-coated or metal-coated metal rods. They are used in shielded metal arc welding, also known as stick welding. The welding rods are designed to conduct electric current to the arc while providing filler metal to create a bond on the piece you’re working on.

sheet metal strips for sale

So, what is the best all-around welding rod? The best all-around welding rod would be the 6011, especially for the DIY’er and hobbyist. With 3/32 and 1/8 size rods on hand, the 6011 will get the majority of your jobs done. It is a fast-fill freeze rod, runs on both AC/DC, and handles dirty contaminated jobs better than other electrodes.

sheet metal stamping fabrication from china

The advantage of the small diameter is that the 1/16″ will create an arc at much lower Amps and therefore also have less heat input, which creates warping in the metal sheet. Setting up the Stick Welder for Sheet Metal. Welding sheet metal DC electrode negative (DCEN) is the best setting due to the higher deposition rate. Top 9 Best Welding Rods in 2024 Reviews and Buyer’s Guide: You can find a huge variety of welding blades in the market, but which one to buy is the real question. Worry not as here are the 10 best welding rods that you can buy. All welding rods mentioned here are equally good, the difference only lies in price and some feature differences.

At Approved Sheet Metal, we find that welding sheet metal is one of the most misunderstood processes in precision sheet metal fabrication. In an effort to demystify welding and help our customers choose the optimal welding method for a part, we do our best to clearly outline the benefits and limitations of different custom welding techniques. Sheet metal is metal that is processed into thin and flat sheets Trusted Source Sheet metal - Wikipedia In most of the world, sheet metal thickness is consistently specified in millimeters. en.wikipedia.org , which is where it gets its name. For sheet metal welding, you need to have much more skill and precision as compared to other forms of .

To weld sheet metal with solid wires, use electrode positive (EP, or reverse polarity). Don’t attempt to weld thin materials like sheet metal with flux-cored wires, which put more heat into the base metal. TIG welding sheet metal. Forget the larger 1/8-inch tungsten electrode and use a smaller one. Lastly, if you are in fact, welding and not brazing, you can expect the sheet metal to warp as a natural reaction to applying heat to the steel. Again you will need to use the hammer weld technique to keep the warping to a minimum. Sheet metal welding is a difficult and time consuming process because of the warpage problem.Step four: weld the metal. When welding the metal the best thing to do is strike it like a match. To avoid burn through, strike the arch and chip it away before striking it again. . Ans: One of the best electrodes to use for sheet metal is .It works in all positions and offers a medium penetrating capability. Ideal for welding sheet metal and applications that are low current. The E6013 Electrode. . Best E6011 Welding Rod for Vertical Welding. 2. Hobart 6011 Stick .

MIG is one of the best ways to weld 20-gauge sheet metal. MIG welding is one of the simplest to use for welding. It is an arc welding process that where you feed a solid wire electrode through a welding gun. . This should be matched to the . Some say it is a sheet metal rod.fine, so it is. But I have made high quality, fast welds with it for serious repair. It is all in joint prep and technique. Hobart's AC7018 rod is the best AC 7018 rod I have found. It is stamped AC7018 on the rod. A 7014 welds fine on AC. Serious speed with this rod. Makes beautiful shiny "dimes".

6011 Vs 6013 Which ROD and Polarity is BEST for WELDING SHEET METAL? Have you ever wondered what the difference is between 6011 and 6013 electrodes and what.

It will ,however you will see a sort of "muddy" puddle with the gas torch because the extra de-oxidizers added for TIG welding will float on the surface of the puddle. The proper rod to use is an R45 designation, a mild steel fusion gas welding rod that will give a nice clean puddle with a neutral flame and a good strong weld. Select your welding rod based on the size of the metal. You can use a welding rod of any size as long as it works with your welder. Keep in mind that a bigger rod is going to weld a larger area than a smaller rod. There are no unique, or galvanized steel-specific tools or materials that you need. Use a 6013, 7018, 6011, or 6010 welding rod.

Use the right equipment: MIG welding requires a power source, a wire feeder, a gun, and a gas cylinder. It is important to use equipment that is designed for MIG welding and that is in good working condition. Choose the right type of material: MIG welding is suitable for a wide range of sheet metal thicknesses and materials, including mild steel, aluminum, and stainless . What is the best way to weld thin metal? MIG welding is a great solution for welding thin metal. However, TIG welding is probably the best solution but it can be the hardest to learn use. With the proper setting, a MIG welder can work great for welding thin metal together. In this guide, we will be discussing the best way to work with thin .

Sheet metal welding can be easy if you apply the necessary technique. A welder does not have to have problems with adjusting the welding machine if they apply the necessary methods. . Best Stick Welding Rods; How much do TIG welders make In 2024? Best 220V Welders – MIG/TIG/Stick & Multi-Process – reviews & Buyer’s Guide 2024 . A 6010 and a 6011 are virtually the same rod, except the 6010 is designed for DC welding. 6013 is generally considered as a sheet metal rod. It has a very heavy flux coat that often lets it be used as a "drag rod" -- you just set the rod on the steel at the right angle and drag it along - there is no need to try to hold an arc length. In general, copper-coated or brass welding rods are ideal for welding thin sheet metal. . The best welding rod for TIG welding thin metal is a pure tungsten rod or a zirconium tungsten rod. MIG welding, on the other hand, is faster and easier to use but may not be as precise as TIG welding. For MIG welding, a copper-coated steel wire is ideal .

Sheet metal welding is a vital aspect of sheet metal fabrication. . You must have the proper knowledge and skills to get the best possible results in a welding job. Sheet metal welding is a great way to save time on your projects. . Arc welding is a type of welding process that uses an electric current to melt metal wire or rod and fuse it .

welding rod differences chart

Shop waterproof electrical boxes, covers, and accessories from a variety of brands like Arlington and more . Order online today with fast shipping and easy returns.

what is the best welding rod for sheet metal|most commonly used welding rods