what is sheet metal used for Hand-hammered metal sheets have been used since ancient times for architectural purposes. Water-powered rolling mills replaced the manual process in the late 17th century. The . See more $38.00

0 · which thickness called sheet metal

1 · what is sheet metalworking

2 · sheet metal examples

3 · most common sheet metal material

4 · metal sheet thickness in mm

5 · material used in sheet metal

6 · disadvantages of sheet metal

7 · characteristics of sheet metal

$100.00

Sheet metal is metal formed into thin, flat pieces, usually by an industrial process. Thicknesses can vary significantly; extremely thin sheets are considered foil or leaf, and pieces thicker than 6 mm (0.25 in) are considered plate, such as plate steel, a class of structural steel. Sheet metal is available in flat pieces or . See more

cnc machine cours

Hand-hammered metal sheets have been used since ancient times for architectural purposes. Water-powered rolling mills replaced the manual process in the late 17th century. The . See moreBendingThe equation for estimating the maximum bending force is,$${\displaystyle F_{\text{max}}=k{\frac {TLt^{2}}{W}}}$$,where k is a factor taking into account several parameters . See moreFasteners that are commonly used on sheet metal include: clecos, rivets, and sheet metal screws. See more

which thickness called sheet metal

• "Manufacturers Standard Gauge History". Steel Market Update. Archived from the original on 2013-09-28. Retrieved 2013-06-19.• "Sheet Steel Gauges and Thicknesses" (PDF). Sheet Steel Facts. Sachiya Steel International. . See moreStainless steelGrade 304 is the most common of the three grades. It offers good corrosion resistance while . See more

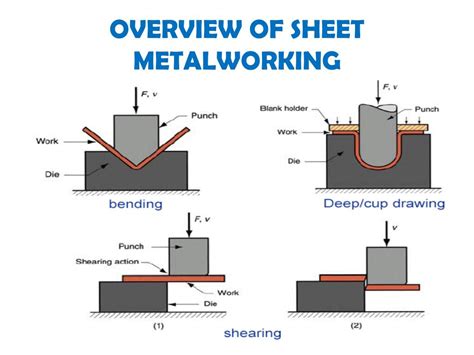

The use of sheet metal, through a comprehensive cold working process, including bending, shearing, punching, laser cutting, water jet cutting, riveting, splicing, etc. to make the final product we want (such as computer chassis, washing machine shells, . See more• Circle grid analysis• Corrugated galvanised iron, also known as Corrugated Sheet Metal• Diamond plate• Forming limit diagram See moreSheet metal is metal formed into thin, flat pieces, usually by an industrial process. Thicknesses can vary significantly; extremely thin sheets are considered foil or leaf, and pieces thicker than .What is Sheet Metal? Sheet metal is metal formed by an industrial process into thin, flat pieces. Sheet metal is one of the fundamental forms used in metalworking, and it can be cut and bent into a variety of shapes. Countless .

what is sheet metalworking

sheet metal examples

Sheet metal is used for both structural and aesthetic purposes, and nearly every skilled tradesperson has worked with various types of sheet metals in some way. Here are .

Table of Contents hide. I What Is Sheet Metal? II Common Materials. III Standard Sizes. IV Hot-Rolled vs Cold-Rolled Sheet Metal. V Forming Processes for Sheet Metal. What Is Sheet Metal? Sheet metal is one .

Stainless Steel. Known for its exceptional resistance to rust and corrosion, stainless steel is often used in applications exposed to moisture or harsh chemicals. It’s a popular .

Blog. What is Sheet Metal and What is It Used For? Sheet metal is a vital component in numerous industries, playing a crucial role in the manufacturing and construction sectors. It's versatility and unique properties make it an . Sheet metal is generally composed of thin and flat sheets of metallic material. Its versatility makes it very useful for a broad range of applications and manufacturing processes. Steel: As one of the most common sheet metals, steel is valued for its strength and durability. Manufacturers in construction, automotive, and appliance sectors widely use it for its tensile strength and relatively low cost. .Sheet metal doors in a stone doorframe is the only situation where sheet metal ever makes sense. Well, that and emergency repairs where you happen to not have any stone and need to upgrade twigs or wood. Reply reply .

Uses of Copper Sheet Metal. Copper sheet metal for sale is made from mined copper ore that goes through cleaning, crushing, milling, several chemical processes, purifying, and melting. Copper sheet metal for sale is . While pure aluminum lacks the strength for structural applications, its alloys are extensively used in sheet metal processing due to their enhanced mechanical properties. Aluminum alloy plates are categorized into eight series .

Sheet Metal is arguably one of best component deals at outpost. If we give 100 metal the value of 7 scrap and 1 HQM the value of 6 scrap. The total recycled value of would be 21. Quite close to the outpost cost of 30.Sheet metal is a vital component in numerous industries, playing a crucial role in the manufacturing and construction sectors.It's versatility and unique properties make it an indispensable material for a wide range of applications. Understanding sheet metal and its uses can provide valuable insights into the manufacturing processes and products that we .

Welding sheet metal is a very critical process within the modern concept of manufacturing. The construction of metal structures, pipelines, and tanks is among the most common applications for sheet metal welding. Though the process is rather straightforward, it can be complex to achieve quality and efficiently weld thin sheet metals. Understanding the key . In the HVAC industry, sheet metal is the most common material used for ductwork and HVAC systems, beating out other materials like polyurethane and fiberglass. What is Sheet Metal? Sheet metal is an all-encompassing term for a thin sheet of a metallic material that, through fabrication, will become a product or structure. Sheet metal can be . Sheet metal screws are widely used in various applications, ranging from automotive, construction, and HVAC industries. They are commonly used to fasten roof panels, gutters, air conditioning ducts, electrical boxes, and other materials. The most critical aspect when choosing a sheet metal screw is ensuring it is tailored for the specific .

Sheet metal is also very weather resistant as a result of the chemical solution it’s treated with post-fabrication. This chemical solution helps prevent corrosion and even helps with UV resistance. This also means sheet metal is extremely durable. In fact, many homeowners choose metal roofing as a direct result of its durability.

most common sheet metal material

The most common type of metal used for ductwork is galvanized iron. Galvanized iron is commonly used as the construction material for rigid rectangular and spiral ducts. . Sheet Metal Thickness; 0 – 300 mm: 0.6 mm (24 AWG) 350 – 600 mm: 0.8 mm (22 AWG) 650 – 750 mm: 0.8 mm (22 AWG) 800 – 1000 mm: 1.0 mm (20 AWG) 1050 – 1500 mm: 1.0 . What is the sheet metal used for. Sheet metal fabrication part has the advantages of a lightweight, high strength, electrical conductivity (can be used for electromagnetic shielding), low cost, and good mass production performance. It has been widely used in electrical appliances, communications, the automotive industry, medical equipment, and . Shearing is used to cut sheet metal along a straight line, which is helpful when either cutting the material into smaller pieces or trimming its edges. A shearing machine has two blades that slide past each other, like giant scissors, to cut the metal. A sheet has to be placed on the machine, clamped into place, and then its upper blade is .Sheet metal is used because it is sturdy and can withstand the forces of an accident. Sheet metal is not just limited to cars though. It is also used for tanks, airplanes, and other types of vehicles. What makes sheet metal a good choice for making these types of vehicles is .

Known as sheet metal screws, they are used by construction and manufacturing companies to fasten sheet metal. Overview of Sheet Metal Screws. A sheet metal screw is a special type of fastener that’s designed for use with sheet metal. Sheet metal screws are characterized by the presence of exterior threading covering their entire shank.

4. Minimum thickness of metal duct material shall be as listed in Table M1601.1.1(2). Galvanized steel shall conform to ASTM A 653. Metallic ducts shall be fabricated in accordance with SMACNA Duct Construction Standards Metal and Flexible. International Residential Code TABLE M1601.1.1(2) GAGES OF METAL DUCTS AND PLENUMS USED .The Sheet of Metal is an item in The Escapists and The Escapists 2. Can be purchased from fellow inmates, found in desks or stolen from the Metal Shop. The Sheet of Metal is a crafting component. It is also a weak weapon in The Escapists 2. Additionally, it can be placed in the press in the Metal Shop [TE1] / Blacksmith [TE2] job in order to create a License Plate [TE1] / .Sheet metal is used to construct numerous objects with varying thicknesses from extremely thin sheets, also known as foil or leaf, to thicker sheets > 6 mm, also known as plate. Metal sheet thickness is referred to as gauge and ranges from .

What Equipment Is Used in Sheet Metal Forming? Sheet metal forming utilizes a variety of equipment based on the design of the part and the specific process. The common equipment includes punches and dies, which are frequently employed for shearing and cutting to create specific-shaped holes. Bending machines are essential for bending operations . Bending Bending is the most common process, where sheet metal is deformed along a straight axis to create angular or curved profiles. This can be done using machines like press brakes, which apply a precise amount of pressure to bend the metal without breaking it. Air bending, coining, and bottoming are popular bending methods used to achieve different . What is sheet metal? Sheet metal can often be used as a term to vaguely describe a category of metals that can be difficult to actually define. Generally, the criteria for being considered sheet metal is between 0.018” and 0.250” thick. However, inches or centimeters are not the primary measurement of a metal sheet’s thickness.Sheet metal is very good in the early stages of a server right after a wipe. On vanilla servers that is. Your base will be much more secure than a stone one from tool raiding although sheet metal is a temporary solution since players will eventually get explosives. Personally I think sheet metal and stone should be interchangeable, the same tier.

Fabricated sheet metal is commonly used in the ductwork of HVAC systems. Traditional ductwork is installed in commercial and industrial buildings for the heating and cooling systems. Sometimes, however, the regular metal ductwork must be routed in odd ways, due to various obstacles in the path. Longer piping would be added to get the metal .Sheet Metal is a crafting component that currently is used to create the Heavy Plate Armour shown in in Devblog 149.. Recycling []. When placed in a Recycler, sheet metal will yield: . 3 High Quality Metal; 100 Metal Fragments Be aware that this metal will not likely be ordinary mild steel. Comment. Post Cancel. dcsound. Senior Member. Join Date: Jun 2004; Posts: 103; Share Tweet #4. 03-30-2005, 05:58 PM. The vehicle I'm planning to work on is a 1997 Jeep Grand Cherokee. I'm trying to do the work myself or myself with a few friends as a learning experience and to try .

Common Materials Used in Sheet Metal Fabrication. Various metals and alloys are employed in sheet metal fabrication, each possessing unique properties suited for specific applications. The most commonly used materials include: Steel: Steel is a popular choice due to its strength, durability, and cost-effectiveness. Carbon steel, stainless steel .This metal sheet is also often used in the building and construction industry for items that include sidings, drains, and much more. Aluminum metal sheet is also ideal for the purpose of manufacturing metal nameplates and other similar items. Aluminum sheets are used often for making motor vehicle number plates due to the fact they are .

Cold rolling is commonly used for producing sheet metal products with precise tolerances and smooth surfaces. Warm rolling is similar to cold rolling, but it is done at elevated temperatures that are just below the recrystallization temperature of the metal. This process helps to further reduce the thickness of the sheet and improve its ductility.

metal sheet thickness in mm

A sluice box should be set with a 4-8 degree angle. Another rule of thumb is that the sluice should be angled to drop roughly 2 inches per foot of length. The exact angle depends on the size and weight of the material, the riffle design, and the speed of the current.

what is sheet metal used for|material used in sheet metal