what is sheet metal in solidworks Sheet metal is the metal formed into thin and flat pieces, which uses sheets of thickness less than 6 mm. It is one of the main and basic forms of metal working. You can cut . Allen Trench Safety has a wide selection of used trench boxes for sale at deeply discounted prices. All of our used trench boxes are in excellent condition and have passed a series of thorough inspections and meet all code requirements.

0 · solidworks sheet metal template

1 · solidworks sheet metal examples

2 · solidworks sheet metal download

3 · solidworks sheet metal cut list

4 · solidworks sheet metal basics

5 · sheet metal solidworks pdf

6 · sheet metal modeling in solidworks

7 · sheet metal in solidworks 2021

Flooring at ReStore is a great deal for you, the environment, and our local .

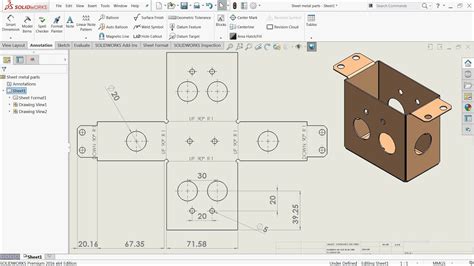

To start, open a new Part document in Solidworks. The Sheet Metal tab is only accessible in Part mode. You can not create Sheet Metal . See moreThere are multiple methods for making sheet metal parts in Solidworks using the Sheet Metal tab. In this article, we will look at using the Sketched Bend feature and also the Edge . See moreCongratulations. You have made a bracket using the sheet metal features in Solidworks. In future articles, we will look at the more advanced sheet metal features, and we will . See moreSheet Metal. Sheet metal parts are generally used as enclosures for components or to provide support to other components. You can design a sheet metal part on its own without any .

Sheet metal is the metal formed into thin and flat pieces, which uses sheets of thickness less than 6 mm. It is one of the main and basic forms of metal working. You can cut . SOLIDWORKS 3D allows you to quickly create sheet metal part designs using a simple design process, saving you time and development costs, thanks to specific sheet metal features. We can use these features to create .

SOLIDWORKS has specific sheet metal features that allow the creation of sheet metal bodies very quickly. However, in some circumstances, when the design demands certain types of . By the end of this tutorial, you'll be well-equipped to design your own sheet metal components confidently in SolidWorks. Music: Inspire by Wavecont https://protunes.net Video Link: •. For example, you could easily define the part’s material to be “AISI 304 Steel” but then select a Gauge Table for Aluminum in the Sheet Metal Properties. No longer! SOLIDWORKS 2019 introduces some new intelligence . In this lesson, you create the sheet metal part. This lesson demonstrates: 1.Creating a base flange 2.Adding a miter flange 3.Mirroring the part and creating.

Sheet metal parts are made with a constant thickness. They start out as one flat sheet and then are cut and bent to make the final product. When it comes to creating a sheet metal part in SOLIDWORKS you have two choices . The Solidworks Sheetmetal Design and Developments software is a powerful tool for designing and developing sheet metal products with ease and precision. Whether you are creating simple brackets or complex enclosures, .First Look: 3D SheetMetal Creator 2 minutes SOLIDWORKS Cloud Offer Sheet Metal Design for All. It is time to start building components, assemblies, enclosures, and more with purpose-built, associative parametric sheet metal . Learn solidworks basic tutorial for beginner how to add sheet metal tab and toolbar#solidworks#howto#mufasucad.

To start, open a new Part document in Solidworks. The Sheet Metal tab is only accessible in Part mode. You can not create Sheet Metal parts in Assembly mode (but you can assemble multiple sheet metal parts there after .

solidworks sheet metal template

solidworks sheet metal examples

76K subscribers in the SolidWorks community. ALL posts related to SOLIDWORKS are welcome. Share what you know. . You can try using sheet metal gauge tables or setting your sheet metal thickness equal to a variable you create and modifying the variable value to drive the dimension, but sheet metal gauge table are the way to go in my opinion. .SOLIDWORKS Tutorial - Sheet Metal Are you familiar with the vast capabilities of SOLIDWORKS sheet metal? Whether you are a novice or intermediate user, this webinar is for you. This module in SOLIDWORKS is designed to reflect the manufacturing procedures you would use on the production floor. This way the bridge between design and manufacture .

The individual sheet metal parts are inserted into the weldment part. However, if the weldment contains extrusions then those compoments are all created inside the weldment due to the ease of generating a cut list, creating paths using 3-D sketches, and .

Mirroring the Sheet Metal Bends. When you mirror a sheet metal part, many of the bends are mirrored as well. Creating an Edge Flange. Create an edge flange using the edit sketch profile and offset options. Mirroring a Sheet Metal Feature. You can mirror sheet metal bodies as well as selected sheet metal features.Open a sheet metal part. In the FeatureManager ® design tree, right-click Material and click Edit Material.; In the dialog box: Right-click Custom Materials and click New Category.; Right-click New Category and click New Material.; Set the custom material properties on .I just wish the SW devs would separate the sheet metal from 3D modeling . Solidworks is a little clunky at times, but it's a lot more powerful, especially in a large workplace setting where a lot of people are working collaboratively, or when you are doing data/table driven modeling or iterative design. For instance, you can set bend tables .

We will need 7 sheets of material and produce 15 parts per sheet, except the last sheet with only 10 parts. Scrap estimation is 39.41%. If we make any changes to our component, sheet size, quantity, or offsets, we can quickly update our estimate. In this case, I’ve increased the width of the part and increased both the part and sheet offsets . SOLIDWORKS 3D allows you to quickly create sheet metal part designs using a simple design process, saving you time and development costs, thanks to specific sheet metal features. We can use these features to create sheet metal designs with several different methods.This is the case most of the time whether you're building sheet metal or other types of parts. Avoid multi-body parts unless you have a specific reason that requires multi-bodys. Reply reply

I don't think you're making that in SolidWorks, to be honest. The flat part, sure. But if you tried to get SolidWorks to turn it into the finished product, it's gonna fart and shit itself before it's 10% of the way there. This seems like the kinda thing you design as a flat, and prove concept using your hands on a prototype.Help with edges flatten sheet metal . CAD Hi folks, I have an issue on the production stage. There is some issues, I was discussing 1mm metal thikness, but for some reasons was used 1,5mm. However after the flatten feature has been applied obviously it should looks differently I think it should be a shape of square. . SolidWorks TOOLCHEKER .Creating sheet metal features is not appropriate in that mode so they are grayed out. Clicking the button in the top right of the viewport will bring you back out of this to the folded state of the model. If you are trying to flatten the model to .

Learn how to convert a regular solid into a sheet metal part using the rip feature in SOLIDWORKS. Explore our library of SOLIDWORKS tutorials today: https://.Sheet Metal - Outer Cutting Length. JS By John Stoltzfus 08/17/11. Good morning, I understand that in 2011 SW you can get the inner & outer cutting lenghts for parts. . ©2002-2024 Dassault Systemes SolidWorks Corporation .When you add a weldment cut list in the drawing, right click on the top of one of the columns and insert new column, the design tree area will ask you what you want that column will auto populate with, select the component properties bubble and then you’ll have access to a drop down menu, sheetmetal thickness, bounding box height/ width, and many many more. create a table as . Hello, I before I export to dxf or step I want to know if the part is sheet-metal. (If sheet metal then export to dxf and step else only export step) I found this code that gives met statistics and the names and type of the features but sheet-metal = type 22 and Cut-Extrude = type 22 an M4 Tapped Hole = type 22 flat pattern = type 22 and the .

The depth of a tab feature is automatically set to the thickness of the sheet metal part. The direction of the depth automatically coincides with the sheet metal part to prevent a disjoint body. . SOLIDWORKS welcomes your feedback concerning the presentation, accuracy, and thoroughness of the documentation. Use the form below to send your .

Click Insert Bends (Sheet Metal toolbar) or Insert > Sheet Metal > Bends.; In the PropertyManager, under Bend Parameters:. Click a face or edge on the model for Fixed Face or Edge.The fixed face remains in place when the part is flattened. Set a value for Bend Radius.; Under Bend Allowance, select from: Bend Table, K-Factor, Bend Allowance, Bend Deduction, .Honest question. why bother with parametric sheet metal features? I do a lot of sheet metal design and honestly find the tool to be extremely limiting. I’d rather just create a global thickness variable and model the geo natively as nature intended rather than spend my time finding creative ways to work around the limitations of the sheet .When I do simulation with sheet metal part, It converts the sheet metal into a tiny layer of mesh. With any other parts, which are not created as sheet metal, thickness is also there after turning the part into mesh.76K subscribers in the SolidWorks community. ALL posts related to SOLIDWORKS are welcome. Share what you know. . I know this is inanely simple, but I cannot get the sheet metal tab to dock at the top with the rest of the toolbars. Dragging to the selection yields no .

Right click on a body and Export to DXF/DWG (or save as and change the file type to DXF or DWG). Save the initial file, but then in the DXF/DWG Output dialog change the export type to Sheet Metal and select all of the sheet metal bodies. Choose which entities you want to export and select "Separate Files" at the bottom. SOLIDWORKS: Category: Assemblies: Similar questions. How to design this product with sheet metal with solid works . 1 answer 334 views 0 followers hello I want to create edge flange in Sheet Metal in solid works with Flange Length/Up to the edge and merge but i do not know how I can do that please give some instructure .thank you. 1 answer .

As a Sheet metal part, this, should be 3 features: a "thin" base flange drawn from the side the notch cut fillet (you have 6 flattening features not 7, but that's just pedantic) You show a screen-capped series of feature trees at the bottom, Are you unsuppressing pieces gradually? . What are the steps to create this cage on SolidWorks? (It is .

solidworks sheet metal download

jobox steel underbody truck tool boxes

Part Duplication Guidelines And Procedure Getting Started - 2 Safety and Usage Guidelines When running an automated machine tool, safety is of the utmost importance. For proper and safe use of the CNC program and your CNC machine, the following safety guidelines must be followed: 1. Never let the machine tool run unattended. 2.

what is sheet metal in solidworks|solidworks sheet metal template