bent sheet metal products In this comprehensive guide, we delve into the intricate processes of Sheet Metal Bending, the vital role of Press Brakes, and the transformative impact they have in industries ranging from automotive to aerospace.

The Truck-Lite 50600 junction box features a larger internal area and 50% more harness ports. This makes it easier to expand and work on the electrical connections.Super 50, 8-Port, 8 Terminal, Grey/Black Plastic, Surface Mount, Junction Box, Kit

0 · types of bending sheet metal

1 · sheet metal cutting and bending

2 · sheet metal bending near me

3 · sheet metal bending dies

4 · maximum thickness sheet metal bending

5 · hand bending sheet metal

6 · bending tool for sheet metal

7 · bending galvanized sheet metal

Quality Sheet Metal Fabrications. 1048 South Cherry Avenue, Tucson, Arizona 85719, United States (520) 745-5728

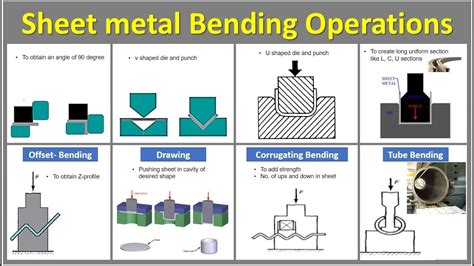

This guide explores sheet metal bending processes, materials suitable for bending, factors to consider and design tips for bending sheet metal parts.Let us look at the most common sheet metal bending methods: V-bending. This is the most fashionable way to bend sheet metal. We use an instrument called the punch and v-die to . Have you ever wondered how to design sheet metal parts for optimal bending? In this blog post, we’ll explore the key principles and best practices for achieving high-quality . Sheet metal bending refers to the fundamental process in metalworking that involves taking flat metal sheets and shaping them into three-dimensional items by applying force. Sheet metal bending is common .

This article will explore the importance of sheet metal bending, its importance in sheet metal fabrication processes, and how to bend sheet metal. It also includes some useful bending tips which can guide on bending steel plates.In this comprehensive guide, we delve into the intricate processes of Sheet Metal Bending, the vital role of Press Brakes, and the transformative impact they have in industries ranging from automotive to aerospace.

Sheet metal bending types and techniques, including press brake and metal bending processes. Learn about the different methods and applications in bending sheet metal fabrication for various manufacturing needs. How do you achieve precise bends in sheet metal? Understanding the molds and techniques behind this process is crucial. This article delves into various bending methods, from free bending to corrective bending, highlighting . From concept to finished product, sheet metal bending requires a deliberate, thought-out design and intentional manufacturing. There are a few major steps to successful bending: 1: Initial Design. 2: Preparing Your File. 3: .

This guide explores sheet metal bending processes, materials suitable for bending, factors to consider and design tips for bending sheet metal parts. From basic concepts to advanced techniques, this guide covers everything you need to know about sheet metal bending. Learn about the different bending methods, tools, and tips to achieve accurate and high-quality results.

Let us look at the most common sheet metal bending methods: V-bending. This is the most fashionable way to bend sheet metal. We use an instrument called the punch and v-die to bend the sheet metal at the angle we need. During the process, the bending punch pushes down on the sheet metal that is sitting on the V-die. Have you ever wondered how to design sheet metal parts for optimal bending? In this blog post, we’ll explore the key principles and best practices for achieving high-quality bends while avoiding common pitfalls. Sheet metal bending refers to the fundamental process in metalworking that involves taking flat metal sheets and shaping them into three-dimensional items by applying force. Sheet metal bending is common throughout various industries, including manufacturing, construction, automotive, and aerospace. Learn more about the process below.

This article will explore the importance of sheet metal bending, its importance in sheet metal fabrication processes, and how to bend sheet metal. It also includes some useful bending tips which can guide on bending steel plates.In this comprehensive guide, we delve into the intricate processes of Sheet Metal Bending, the vital role of Press Brakes, and the transformative impact they have in industries ranging from automotive to aerospace.Sheet metal bending types and techniques, including press brake and metal bending processes. Learn about the different methods and applications in bending sheet metal fabrication for various manufacturing needs.

How do you achieve precise bends in sheet metal? Understanding the molds and techniques behind this process is crucial. This article delves into various bending methods, from free bending to corrective bending, highlighting their applications and advantages. From concept to finished product, sheet metal bending requires a deliberate, thought-out design and intentional manufacturing. There are a few major steps to successful bending: 1: Initial Design. 2: Preparing Your File. 3: The Bending Process. 4: Finishing Processes.This guide explores sheet metal bending processes, materials suitable for bending, factors to consider and design tips for bending sheet metal parts. From basic concepts to advanced techniques, this guide covers everything you need to know about sheet metal bending. Learn about the different bending methods, tools, and tips to achieve accurate and high-quality results.

Let us look at the most common sheet metal bending methods: V-bending. This is the most fashionable way to bend sheet metal. We use an instrument called the punch and v-die to bend the sheet metal at the angle we need. During the process, the bending punch pushes down on the sheet metal that is sitting on the V-die.

Have you ever wondered how to design sheet metal parts for optimal bending? In this blog post, we’ll explore the key principles and best practices for achieving high-quality bends while avoiding common pitfalls. Sheet metal bending refers to the fundamental process in metalworking that involves taking flat metal sheets and shaping them into three-dimensional items by applying force. Sheet metal bending is common throughout various industries, including manufacturing, construction, automotive, and aerospace. Learn more about the process below.

This article will explore the importance of sheet metal bending, its importance in sheet metal fabrication processes, and how to bend sheet metal. It also includes some useful bending tips which can guide on bending steel plates.In this comprehensive guide, we delve into the intricate processes of Sheet Metal Bending, the vital role of Press Brakes, and the transformative impact they have in industries ranging from automotive to aerospace.Sheet metal bending types and techniques, including press brake and metal bending processes. Learn about the different methods and applications in bending sheet metal fabrication for various manufacturing needs.

types of bending sheet metal

How do you achieve precise bends in sheet metal? Understanding the molds and techniques behind this process is crucial. This article delves into various bending methods, from free bending to corrective bending, highlighting their applications and advantages.

cnc lathe machine price in tamilnadu

cnc lathe machine job work in bangalore

Two State Roofing, Inc. Has over 30 years experience in the installation and repair of shingle and metal roofs, and is dedicated to providing the highest quality roofing services. top of page 208-523-8406

bent sheet metal products|hand bending sheet metal