sheet metal processing and fabrication The precision sheet metal fabrication process involves producing precise sheet metal components for vehicles. The process begins with design, followed by cutting, forming, joining, finishing, quality control, and packing.

Since 5-axis milling machines are not that common yet, purchasing and maintaining one is a large investment — and the tooling solutions are equally expensive. Operating a 5-axis machine requires an exceptionally skilled CNC .

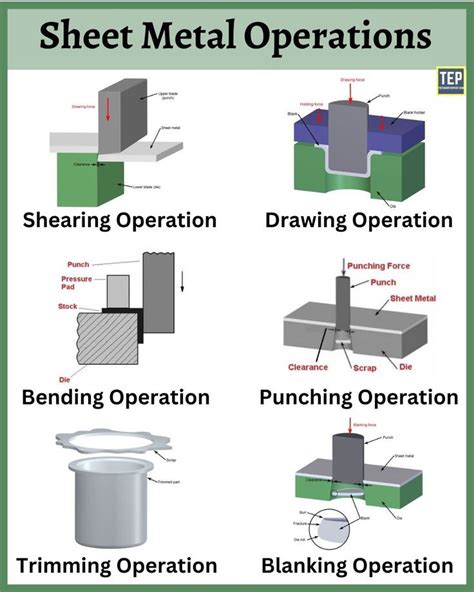

0 · various sheet metal processes

1 · types of sheet metal process

2 · types of sheet metal fabrication

3 · sheet metal process in manufacturing

4 · sheet metal fabrication techniques

5 · sheet metal diagram fabrication

6 · disadvantages of sheet metal

7 · basic sheet metal fabrication techniques

Get top deals, latest trends, and more. Contactless options including Same Day Delivery and Drive Up are available with Target. Shop today to find Bread Boxes at incredible prices.

The manufacturing & design guide. Learn how to effectively design sheet metal parts. This guide starts with the basics and moves toward design best practices and advice on material .

Also known as sheet metal fabrication, sheet metal forming uses metal sheets to make various products and components. The metal sheets are formed and cut into the necessary shape and size via many different .The sheet metal fabrication process is an intricate journey from raw metal to a finished product. It involves various steps, ensuring the final product meets specific standards and functions. In .Custom online sheet metal fabrication services, prototypes, and formed parts in aluminum, copper, brass, steel, and stainless steel. Instant online fabrication quotes, engineering .What is Sheet metal fabrication? A complete guide on processes, applications, pros, and cons. Discover essential tips and techniques in our comprehensive guide to sheet metal fabrication for both beginners and professionals.

The precision sheet metal fabrication process involves producing precise sheet metal components for vehicles. The process begins with design, followed by cutting, forming, joining, finishing, quality control, and packing. Sheet metal fabrication is the process of turning flat sheets of steel, aluminum, titanium or other metals into metal structures or products. This transformation is achieved through a series of techniques such as cutting, .

various sheet metal processes

Sheet metal manufacturing is the process of creating sheet metal parts by cutting, bending, and forming thin metal sheets into specific shapes and sizes. The process typically uses coating, cutting, bending, and assembly techniques.Sheet metal processing is a method that manipulates flat sheets of metal into desired shapes and structures. Understanding the sheet metal forming process gives us insights into the world of manufacturing, revealing the ingenious .We are a Latvian metalworking, sheet metal processing and fabrication company. We offer metal laser cutting, bending and folding and fabricated part aftertreatment services. Our end product is sheet metal parts: blank pieces .

Post-processing in sheet metal fabrication comprises operations carried out after fabrication that enhance the quality of the fabricated part. Post-processing operations may be aesthetic, improving the part’s appearance, or functional, . Discover the top 10 CAD/CAM software solutions for sheet metal and tube processing. Boost productivity, streamline workflows, and create advanced parts with industry-leading design and manufacturing tools. . Sheet .Experienced metal fabrication manufacturer since 2008. ISO 9001 certified. 8,200 m2 factory. Professional OEM/ODM/custom precise sheet metal processing servicesGet an overview to sheet metal fabrication from the different types of sheet metal fabrication, to design best practices, materials, finishings and fastenings. 20% off your first order. Save up to ,000/€1,000. Ends 30 Nov 2024. . but it can also create longer processing times. For example, a laser cutter cannot make tiny holes, so a .

Sheet metal deforming processes involve changing and processing sheet metal without cutting it. Bending is one of the most critical forming processes, and it can be done using a brake machine. A sheet metal company can use this tool to bend sheet metal into V, U, and channels up to 120 degrees. . The spinning sheet metal fabrication process .

The core machinery in a modern sheet metal fabrication facility encompasses a diverse range of sophisticated equipment designed to handle various aspects of metal processing. This typically includes: Material Preparation: Decoiler: For unwinding coiled sheet metal; Leveler: To flatten and remove coil set from sheet metal; Cutting Technologies:We are a complete one-stop sheet metal processing service with our own factory. Our services range from sheet metal design to expansion drawings, laser cutting, punching, bending, welding and powder coating. . In short, BLIKSEN can provide a one-stop service to solve sheet metal fabrication such as steel, aluminium, stainless steel, copper .The efficiency and high precision of sheet metal fabrication, coupled with Xometry’s variety of materials, range of sheet metal fabricators, and post-processing options means you can get parts for any application. Sheet metal applications include aerospace, defense, automotive, energy, industrial, medical, dental, and consumer products. .People often use the terms "sheet metal stamping" and "metal fabrication" interchangeably, but they refer to a range of manufacturing processes with significant differences. 800-486-5546. 800-486-5546. . — Secondary processing available; If you require parts manufactured in large numbers, you may benefit from sheet metal stamping over metal .

Sheet metal fabrication Precision CNC sheet cutting, bending, stamping, punching, nibbling for series Complex metal parts fabrication Metal parts fabrication of sheet metal, tube, pipe, etc for small to large series Machining Drilling, tapping on sheet metal fabricated parts, welding or other fabrication of tube, pipe, etc.ESTABLISHED 2020 With a combined 30 years in the structural steel and sheet metal processing industry ABOUT US what we do. M.P.H. Metals Processing, Inc. was formed in 2020 with a core focus in providing the best available steel processing services for our customers. . Our comprehensive sheet metal and structural steel fabrication .

When you need reliable aircraft sheet metal fabrication services, count on Capps Manufacturing.We have the experience, capabilities and equipment to fabricate quality aircraft sheet metal parts and assemblies at our facility in Wichita, KS. In fact, we can manufacture most component parts and tooling for any assembly in-house. We serve general aviation, military .Avon Lake Sheet Metal has over 60 years of experience as a leader in Cleveland area sheet metal & structural steel fabrication services, construction & design. Skip to content. Call Us Today 440-933-3505. Search. Search. Search. Search. Close this search box. Menu. . • Food Processing • General Manufacturing • RetailSince 1974, K.K.Metal specialize in precision sheet metal fabrication & provide one stop metal fabrication solution for various international industries. google-site-verification=kOMpLcUsN6l8wSNb1_5ttUE0OrojkifeWb6jfazeMRk .Our team of skilled professionals, with years of experience in sheet metal fabrication, is dedicated to delivering top-quality results for your projects. 2. Advanced Technology. We employ cutting-edge equipment and techniques, .

CNC Sheet Metal Processing: Equipped with state-of-the-art CNC technology, Horizon's sheet metal processing capabilities redefine precision. Our 4000 Watt Laser ensures swift and accurate cutting, while CNC operations elevate the .

Laser cutting is a metal fabrication process that uses a thin, computer-controlled laser to cut through metal—such as stainless steel, aluminum, and more. The material melts, burns, vaporizes, or is blown away by a jet of gas, leaving an edge with a high-quality surface finish. Laser cutting is an efficient sheet metal processing technique. Sheet metal fabrication is a process that involves the creation of objects from thin sheets of metal. It can involve everything from simple shapes to more complex designs. . Sheet metal processing commonly used materials are cold rolled sheet (SPCC), hot rolled sheet (SHCC), galvanized sheet (SECC, SGCC), copper (CU), brass, red copper .

Modern CNC machinery used for sheet metal processing grant top quality and efficiency of work in cases of complex workpieces. We have the potential of delivering full product fabrication by using CNC laser cutting, CNC puncing presses and press brakes and ofcourse the final processing of steel metal sheet workpieces, including all indurstiral surface treatments. surface .Nhat Nam Sheet Metal Fabrication Co.,LTD in Vietnam was established in 2016, specializing in cutting, bending, stamping, welding, powder coating for sheet metal. . and dies. If assembly or post -processing is required, our sheet metal manufacturers will weld, add inserts, or finish the part. The efficiency and high precision of sheet metal .

CUTTING EDGE Materials Processing Corporation offers large format, high-precision sheet metal fabrication for the construction and industrial sectors of the Philippines.. Cutting Edge’s superior products are unparalleled in quality and innovation. They are created using an origami-like technique where a 2D thin sheet of metal is cut and formed into its desired shape and function .

Sheet metal fabrication is a crucial process in various industries, including automotive, aerospace, construction, and electronics. The ability to accurately estimate the cost and time required for sheet metal fabrication projects is essential for maintaining profitability .

Our sheet metal fabrication process Made in Hungary Technological excellence and expertise Variety of custom solutions Flexible high and low quantity production Contract manufacturing made to fit your supply chain Competitive prices with high quality Get a quote Precision sheet metal parts made with experience Our sheet metal processing .Learn more about stainless steel sheet metal fabrication services and get started on a custom quote today. . They are also easy to clean, making them well suited for food processing applications. Stainless steel is widely used as a material for sheet metal parts. It has excellent corrosion resistance, good mechanical properties, and top-notch .Since the processing of sheet metal parts is completed according to the corresponding mold, the bending radius is also equivalent to the size of the mold. Therefore, under the premise of no special requirements, the bending radius can be calculated by adopting the size equivalent to the mold, and the actual bending radius should not be paid too .Your Best Sheet Metal Fabrication Bring Your Design Into Reality Beska will provide you with a quote within 4 hours. With 17 years of experience, we are committed to providing the most appropriate and efficient service, which makes us a trusted .

types of sheet metal process

The first step to creating perfect packaging is to measure the three dimensions inside your box, not outside — more on why you need to do this later — by using a ruler or tape measure and rounding each result to the nearest whole inch.

sheet metal processing and fabrication|sheet metal fabrication techniques