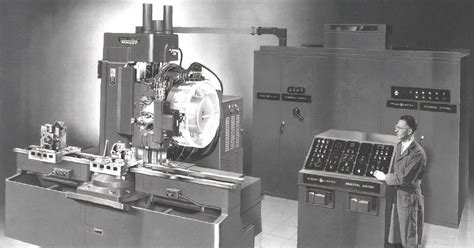

cnc computer numerical control machine CNC machining is the process of using a computer-driven machine tool to produce a part out of solid material in a different shape. The CNC depends on digital instructions usually made on Computer Aided Manufacturing (CAM) or . When conductors come into a junction box in one raceway and exit the box in another raceway (not a straight pull) of a different size, how much distance do you need between those raceways? You need six times the trade .

0 · who invented cnc machine

1 · what is a cnc mill

2 · numerically controlled machine tool

3 · computerized numerical control cnc

4 · computer numerically controlled machine tools

5 · computer numerical control today

6 · computer numerical control cnc programmer

7 · cnc machine full form

Using our advanced review methodology, we’ve evaluated the top metal and steel fabrication software based on value for money, integration options, and supported manufacturing environments. STRUMIS: Best for Structural Metal Fabricators; ProShop ERP: Best for Machine Shops; Fulcrum Pro: Best for Sheet Metal Fabrication

What is CNC: CNC stands for computer numerical control, which is a process of using computer software to control the movement and operation of machines that can cut, .Computer numerical control (CNC) is a manufacturing method that automates the control, movement and precision of machine tools through the use of preprogrammed computer software, which is embedded inside the tools. CNC . CNC stands for Computer Numerical Control and is used to automate machine tools in manufacturing processes. CNC machines are programmed with G-code, a set of computer instructions that control their .CNC machining is the process of using a computer-driven machine tool to produce a part out of solid material in a different shape. The CNC depends on digital instructions usually made on Computer Aided Manufacturing (CAM) or .

who invented cnc machine

what is a cnc mill

The CNC machine process is a highly automated technical program that combines computer numerical control with precision machine tooling. Learn what a CNC machine is and how . Computer numerical control (CNC) is a technology that uses computers to control machines in manufacturing processes. With CNC, computers accurately guide the movements of tools and machinery. The .computer numerical control (CNC), in manufacturing, the control of a device, particularly machine tools, by direct input of data from a computer program. It is a principal element of computer .

CNC machining, also known as Computer Numerical Control machining, uses computer software to control machines and tools, allowing for the production of complex and precise parts with high accuracy and speed. It has .

A CNC (Computer Numerical Control) machine is essentially a computer-controlled tool designed to produce highly precise and consistent parts. It operates like a sophisticated robot, capable of automatically performing cuts, .In machining, numerical control, also called computer numerical control (CNC), [1] is the automated control of tools by means of a computer. [2] It is used to operate tools such as drills , lathes , mills , grinders , routers and 3D printers . What is CNC: CNC stands for computer numerical control, which is a process of using computer software to control the movement and operation of machines that can cut, carve, or engrave materials. Types of CNC machines : There are different types of CNC machines, such as routers, mills, lathes, lasers, and plasma cutters.

cnc machine setup and operation

numerically controlled machine tool

cnc machine setup template

Computer numerical control (CNC) is a manufacturing method that automates the control, movement and precision of machine tools through the use of preprogrammed computer software, which is embedded inside the tools. CNC is commonly used in manufacturing for machining metal and plastic parts. CNC stands for Computer Numerical Control and is used to automate machine tools in manufacturing processes. CNC machines are programmed with G-code, a set of computer instructions that control their movements and operations. CNC automation improves productivity, efficiency, and accuracy in manufacturing.CNC machining is the process of using a computer-driven machine tool to produce a part out of solid material in a different shape. The CNC depends on digital instructions usually made on Computer Aided Manufacturing (CAM) or Computer Aided Design (CAD) software like .The CNC machine process is a highly automated technical program that combines computer numerical control with precision machine tooling. Learn what a CNC machine is and how automated CNC machining works to increase productivity, safety and efficiency at .

Computer numerical control (CNC) is a technology that uses computers to control machines in manufacturing processes. With CNC, computers accurately guide the movements of tools and machinery. The machine follows instructions like a person might follow a recipe.

computer numerical control (CNC), in manufacturing, the control of a device, particularly machine tools, by direct input of data from a computer program. It is a principal element of computer-integrated manufacturing. CNC is also essential to the operation of industrial robots. CNC machining, also known as Computer Numerical Control machining, uses computer software to control machines and tools, allowing for the production of complex and precise parts with high accuracy and speed. It has transformed the way manufacturers approach prototyping, production, and customization. A CNC (Computer Numerical Control) machine is essentially a computer-controlled tool designed to produce highly precise and consistent parts. It operates like a sophisticated robot, capable of automatically performing cuts, drilling holes, and molding materials to .

In machining, numerical control, also called computer numerical control (CNC), [1] is the automated control of tools by means of a computer. [2] It is used to operate tools such as drills , lathes , mills , grinders , routers and 3D printers . What is CNC: CNC stands for computer numerical control, which is a process of using computer software to control the movement and operation of machines that can cut, carve, or engrave materials. Types of CNC machines : There are different types of CNC machines, such as routers, mills, lathes, lasers, and plasma cutters.Computer numerical control (CNC) is a manufacturing method that automates the control, movement and precision of machine tools through the use of preprogrammed computer software, which is embedded inside the tools. CNC is commonly used in manufacturing for machining metal and plastic parts.

computerized numerical control cnc

CNC stands for Computer Numerical Control and is used to automate machine tools in manufacturing processes. CNC machines are programmed with G-code, a set of computer instructions that control their movements and operations. CNC automation improves productivity, efficiency, and accuracy in manufacturing.

CNC machining is the process of using a computer-driven machine tool to produce a part out of solid material in a different shape. The CNC depends on digital instructions usually made on Computer Aided Manufacturing (CAM) or Computer Aided Design (CAD) software like .

The CNC machine process is a highly automated technical program that combines computer numerical control with precision machine tooling. Learn what a CNC machine is and how automated CNC machining works to increase productivity, safety and efficiency at .

Computer numerical control (CNC) is a technology that uses computers to control machines in manufacturing processes. With CNC, computers accurately guide the movements of tools and machinery. The machine follows instructions like a person might follow a recipe.computer numerical control (CNC), in manufacturing, the control of a device, particularly machine tools, by direct input of data from a computer program. It is a principal element of computer-integrated manufacturing. CNC is also essential to the operation of industrial robots. CNC machining, also known as Computer Numerical Control machining, uses computer software to control machines and tools, allowing for the production of complex and precise parts with high accuracy and speed. It has transformed the way manufacturers approach prototyping, production, and customization.

cnc machine service engineer jobs in coimbatore

The NEC 2023 includes specific provisions for sizing junction boxes. These requirements ensure that boxes are large enough to accommodate conductors, splices, and other components without causing damage or excessive heat .

cnc computer numerical control machine|who invented cnc machine