complex or tight tolerance precision cnc machining In complex CNC machining, a standard tolerance of +/- 0.0050” is sufficient for most parts. When tighter tolerances are necessary, Reata Engineering can reliably hold tight tolerances of +/- 0.0005” before costs . e:

[email protected] f: 508-588-5690 Matching historic storefronts in Boston gave Weiss Sheet Metal a chance to spotlight their unique fabrication capabilities. This renovation project presented a unique challenge to Weiss, and offered a terrific opportunity to show our capabilities. The client was looking for a radiused

0 · tight tolerances for cutting tools

1 · tight tolerance machining

2 · tight tolerance machine learning

3 · tight tolerance cnc machining

4 · cnc tight tolerances chart

5 · cnc tight tolerance limits

6 · cnc programming tolerances

7 · cnc machine tolerances

Suitable for in-ceiling use for supporting weights up to up to 6 lbs. Perhaps it should say "For support of 20 lb fixture or product when installed in a suitable substrate." There is no mention at all about how the material it's mounted to affects the load capacity. Suppose you had a 3/8" sheetrock ceiling? Or maybe ceiling tile?

Manufacturers can achieve repeatability in dimensions, shapes, and other critical factors by utilizing tight-tolerance CNC machining techniques. This precision is especially vital in the medical device industry where part accuracy is synonymous with patient safety and .

Performing a warmup routine for CNC machines is critical to maintaining close . Specifying tolerances shows the precision needed in CNC turning and milling when manufacturing a component. The smaller the range of acceptable measurements, the tighter the tolerance and the more precise the . In complex CNC machining, a standard tolerance of +/- 0.0050” is sufficient for most parts. When tighter tolerances are necessary, Reata Engineering can reliably hold tight tolerances of +/- 0.0005” before costs . Learn the advantages of precision CNC machining in the manufacture of small, complex parts requiring tight tolerances, smooth .

This article delves into innovative strategies like toolpath optimization, adaptive machining, and tool wear compensation, alongside the integration of AI and IoT, showcasing their pivotal roles .This blog post delves into the fascinating world of complex and tight tolerance precision CNC machining, exploring its importance, applications, and advancements in technology. 1. .

Complex CNC machining plays a pivotal role in fulfilling these demands by enabling the production of parts with tight tolerances, complex geometries, and high . Manufacturers can achieve repeatability in dimensions, shapes, and other critical factors by utilizing tight-tolerance CNC machining techniques. This precision is especially vital in the medical device industry where part accuracy is .

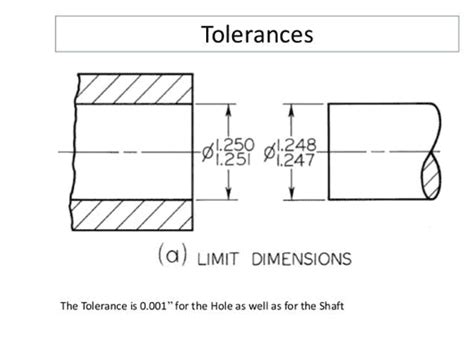

Specifying tolerances shows the precision needed in CNC turning and milling when manufacturing a component. The smaller the range of acceptable measurements, the tighter the tolerance and the more precise the part needs to be.

Performing a warmup routine for CNC machines is critical to maintaining close tolerances and ensuring the ultimate precision of the machining process. As CNC machines heat up during operation, the thermal expansion can cause minute but impactful dimensional changes in the machine components. In complex CNC machining, a standard tolerance of +/- 0.0050” is sufficient for most parts. When tighter tolerances are necessary, Reata Engineering can reliably hold tight tolerances of +/- 0.0005” before costs significantly increase. Learn the advantages of precision CNC machining in the manufacture of small, complex parts requiring tight tolerances, smooth finishes, and repeatability.

This article delves into innovative strategies like toolpath optimization, adaptive machining, and tool wear compensation, alongside the integration of AI and IoT, showcasing their pivotal roles in enhancing CNC machining capabilities for industries demanding high precision.This blog post delves into the fascinating world of complex and tight tolerance precision CNC machining, exploring its importance, applications, and advancements in technology. 1. Understanding Complex CNC Machining Complex CNC machining plays a pivotal role in fulfilling these demands by enabling the production of parts with tight tolerances, complex geometries, and high repeatability. The precision and adaptability offered by complex CNC machining make it indispensable in industries where safety, performance, and reliability are crucial. CNC precision machining stands as a pivotal innovation in modern manufacturing, offering unparalleled accuracy and efficiency in producing complex parts essential across various industries. This sophisticated process harnesses computer numerically controlled machinery (CNC) to adhere to tight tolerances, crucial for the functionality and .

Mastering tight tolerances in CNC machining is all about precision, skill, and attention to detail. By carefully selecting the right tolerances and employing effective strategies, you can enhance both the quality and reliability of your components. Manufacturers can achieve repeatability in dimensions, shapes, and other critical factors by utilizing tight-tolerance CNC machining techniques. This precision is especially vital in the medical device industry where part accuracy is . Specifying tolerances shows the precision needed in CNC turning and milling when manufacturing a component. The smaller the range of acceptable measurements, the tighter the tolerance and the more precise the part needs to be. Performing a warmup routine for CNC machines is critical to maintaining close tolerances and ensuring the ultimate precision of the machining process. As CNC machines heat up during operation, the thermal expansion can cause minute but impactful dimensional changes in the machine components.

In complex CNC machining, a standard tolerance of +/- 0.0050” is sufficient for most parts. When tighter tolerances are necessary, Reata Engineering can reliably hold tight tolerances of +/- 0.0005” before costs significantly increase. Learn the advantages of precision CNC machining in the manufacture of small, complex parts requiring tight tolerances, smooth finishes, and repeatability.

This article delves into innovative strategies like toolpath optimization, adaptive machining, and tool wear compensation, alongside the integration of AI and IoT, showcasing their pivotal roles in enhancing CNC machining capabilities for industries demanding high precision.This blog post delves into the fascinating world of complex and tight tolerance precision CNC machining, exploring its importance, applications, and advancements in technology. 1. Understanding Complex CNC Machining Complex CNC machining plays a pivotal role in fulfilling these demands by enabling the production of parts with tight tolerances, complex geometries, and high repeatability. The precision and adaptability offered by complex CNC machining make it indispensable in industries where safety, performance, and reliability are crucial. CNC precision machining stands as a pivotal innovation in modern manufacturing, offering unparalleled accuracy and efficiency in producing complex parts essential across various industries. This sophisticated process harnesses computer numerically controlled machinery (CNC) to adhere to tight tolerances, crucial for the functionality and .

tight tolerances for cutting tools

1968 gt shelby kr front sheet metal measurements diagram

Yes, it is possible to weld sheet metal with a stick welding machine, but it is the most challenging option due to the aggressive nature of the stick welding process. We would only recommend using a stick welder on sheet metal if you have a very tight budget (and you don’t have access to a TIG or MIG welder) or you are working outdoors (stick .

complex or tight tolerance precision cnc machining|tight tolerance cnc machining