sheet metal box drawing Learn the basics of sheet metal layout including different seams, techniques and tricks. This video also includes the patterns and layout methods for creati. Discover a wide range of used Spot Welders from Clark Machinery Sales. Choose from brands like SCIAKY and more. Explore our extensive inventory and invest in the perfect equipment for your business.

0 · simple sheet metal drawings

1 · sheet metal layout drawings

2 · sheet metal box layout

3 · sheet metal box design template

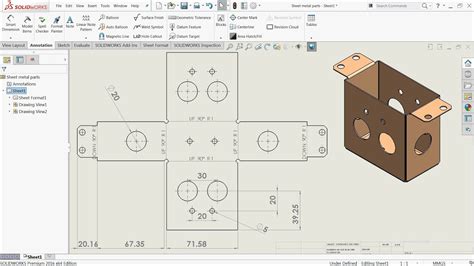

4 · sheet metal 3d sketch solidworks

5 · free sheet metal templates

6 · free sheet metal layout software

7 · flat pattern sheet metal drawing

$167.99

In this Instructable I'm going to walk you through how to make one of these simple sheet metal boxes! If you are just beginning to work with sheet metal I recommend also checking out my .

Sheet metal box drawing onshape. William Derry. 672 subscribers. 1.6K views 1 year ago. Sheet Metal Box + Drawing. Sheet metal is metal formed by an industrial process into thin, flat pieces. Sheet metal is one of the fundamental forms used in metalworking and it . Design and customize a sheet metal box in minutes using eMachineShop’s metal box design wizard. 100k+ CAD Users. 25+ Part Templates and Shapes.

Learn the basics of sheet metal layout including different seams, techniques and tricks. This video also includes the patterns and layout methods for creati.

SOLIDWORKS has specific sheet metal features that allow the creation of sheet metal bodies very quickly. However, in some circumstances, when the design demands certain types of . How to Create Sheet Metal Drawings - Flat Patterns, Cut Lists, Multi-Body Views. In this SOLIDWORKS tutorial, Roland demonstrates how to create detailed drawings and DXFs of different configurations using multi body . Discover the top 5 free CAD software for sheet metal design, including FreeCAD, Onshape, and Fusion 360. Unleash your creativity with these powerful, easy-to-use programs that streamline your sheet metal projects.

A fully dimensioned sheet metal drawing includes dimensions for all bends, holes, countersinks, flanges, and other formed features (such as hems and curls, ribs, dimples, etc.). It is a best practice to dimension to virtual intersection points . Sheet metal is the metal formed into thin and flat pieces, which uses sheets of thickness less than 6 mm. It is one of the main and basic forms of metal working. You can cut or bend into various shapes using sheet metal.

Learn to draw a simple sheet metal profile for designing your own box in OnShape. You will be able to export a DXF of your design to send to your laser cutte.

Figure 5-1: Sheet Metal Box 5.1 REQUIRED VIEWS Formed sheet metal parts must be fully defined as a finished good in the completed (folded) state per section; however, sheet metal parts also require specific data to be shown on the drawing to ensure proper manufacturing and inspection.Deep drawing is fundamentally a metal sheet-forming technique that turns a flat metal sheet into a three-dimensional product. Imagine it as a more specialized version of metal stamping. To execute this technique, position a shaped metal . Using the SOLIDWORKS Sheet Metal Bounding box you can automate the creation of flat pattern data in your related drawing. With over 35 years of experience, the TriMech Group offers a comprehensive range of design, engineering, staffing and manufacturing solutions backed by experience and expertise that is unrivalled in the industry. quickly draw a parametric sheet metal box in solidworks with drawing also

Oct 25, 2024 - Explore Mahtabalam Khan's board "SolidWorks Sheet metal" on Pinterest. See more ideas about solidworks, sheet metal, sheet.

simple sheet metal drawings

5 • Blend Create a sheet metal wall by blending several sections sketched in parallel planes as shown in Figure SM.10. Figure SM.10 Base Feature, Blended Wall • Flat Sketch the boundaries of the wall (Fig. SM.11). Figure SM.11 Feature, Flat Wall • Offset Create a wall that is offset from a surface (Fig. SM.12). Figure SM.12 Base Feature, Offset Wall .

i worked at a large company with a world-class sheet metal manufacturing plant attached. we were required to provide a flat pattern view with each sheet metal drawing, but dimensions were not required. the purpose here was to "prove" that the part in the drawing could be made from a single non-overlapping sheet of metal. basically it was a .Solidworks Sheet Metal Drawings. Kincir Air. Mechanical Sketch. Sheet Metal Drawing. Sheet Metal Design . Base flange, Edge Flange, flatten the parts, how to save as 2D drawing for autocad use, and Appearance in Solidworks sheet metal.#3Dmodellingin. Mahtabalam Khan. Bending. Metal Forming. Cad Design. Machine Tools. . Sketch Power box . I try very hard NOT to try any corner welds on material less than 2-3 mm thick without a lap joint or a tab folded at the corner. 0.9 mm to 0.9 mm at a "free folded corner with no backing metal is very tricky to avoid burn-through and re-re-re-rework.

In order to do this, you simply double click on a column in the BOM and next choose to show the custom property called Bounding Box Area. The finished drawing should look something like the drawing shown below. See Figure 6 and 7 below. Fig. 6 Flat Pattern description and bounding box area Info . Fig. 7 Final drawing with BOM

Sep 10, 2024 - Explore Dejan Vračarević's board "METAL BOX" on Pinterest. See more ideas about metal box, sheet metal, metal. Sheet Metal Drawing Common stretch forms and design considerations. The sheet metal stretch is shown in Figure 1-50. . This size is used in a large number of insert box. It is important to note that this type of connection requires that the bottom nut is anchor rivet nuts.Sheet Metal Deep Drawing Complete Process. So, here is the step-by-step of the Deep Drawing process; . Just like the previous one, it converts metal sheets into taller square boxes. Deep Drawing Forming Method for High Rectangular Boxes: Just like above., it is a formation of square boxes with rectangular geometry. It is widely used to make . Design of Sheet metal Box Assembly using NX-Cad Objective The main objective of this project is to design a sheet metal Box assembly by understanding different operations in Siemens NX-cad. Then Drawing sheet is to be created for the designed sheet metal Box. Introduction Sheet metal is metal formed by an.

Deep drawing is a manufacturing process that is used extensively in the forming of sheet metal into cup or box like structures. Pots and pans for cooking, containers, sinks, automobile parts, such as panels and gas tanks, are among . 2D drawings serve as the bedrock for manufacturing industries, acting as the blueprint for every process, including sheet metal fabrication.These technical drawings encapsulate the design intent, detailing every aspect, from . Junction Box Enclosure Menu Toggle. Street Light Junction Box; NEMA 4 Junction Box; NEMA 3R Junction Box; Applicaton Menu Toggle. Control Station Enclosures; . Sheet metal deep drawing services is an effective and efficient sheet metal forming operation. In this guide, you will find all information about deep drawing – from step-by-step .

Using the square and pen, mark out the lines, edges, notches, and hole placement on the three sheets of metal. Cut and notch all pieces using the tin snips. Drill all 18 holes in body at 1/8", and the two 3/8" holes in the side pieces (for the handle). . Scale your tool box up or down to make another sized carryall. Design a tool shelf that . Steel NEMA 1 Sheet Metal Box . Bud Industries offers the electronics industry a wide range of NEMA box selections formed from sheet metal and meet the exacting NEMA standards including NEMA 4, 4x, IP65 enclosures, IP67 enclosures and IP66 enclosures. Water-tight, environmentally secure and sturdy, these NEMA-rated enclosures are ideal for a . Toolbox Sheet Metal Tutorial 3/4 – How to Create Sheet Metal Drawings – Flat Patterns, Cut Lists, Multi-Body ViewsWhat is Deep Drawing? Deep drawing reshapes flat metal sheets into hollow, three-dimensional forms. This process stretches the material over a die, creating complex shapes without seams or joints. Steps Involved in Deep Drawing Stainless Steel. The deep drawing process follows a series of carefully controlled steps:

Designing a sheet metal box involves several steps to ensure it meets functional and aesthetic requirements. Here’s a general guide to get you started: 1. Define Requirements Dimensions: Length, width, and height. Material: Type of sheet metal (e.g., aluminum, stainless steel, galvanized steel). Thickness: Gauge of the sheet metal. Functionality: Purpose of the .The result is a seamless, robust, and high-quality deep drawn metal product, whether it’s a deep drawn box, an intricate automotive component, or a custom-designed metal part. . It’s a common step in deep drawing sheet metal or deep drawn steel, especially when creating products like beverage cans or shells. 10. Marking Process. we will learn Base flange, Edge Flange, Corner, hemming, Vent,unfold, fold, extruded cut, mirror, Simple Hole, flatten the parts, how to save as 2D drawing f. This video demonstrates how to properly dimension a sheet metal layout technical drawing. It reviews general dimension standards as well as requirements for.

How to Create Your Own Custom 3D Printed IPhone Case: Please check out my Shapeways shop where you can buy iPhone cases such as this one and others such as the TriStand - iPhone case with 3 in 1 built in flip out Kickstands for 3d printing by Shapeways (3d printing service).

sheet metal layout drawings

$845.00

sheet metal box drawing|free sheet metal templates