hemming operation in sheet metal The hemming process can be carried out in one of the following two ways: 1. Die hemming process 2. Roller hemming process See more TayMac innovated “in-use.” The brand manufactures metallic and nonmetallic .

0 · types of sheet metal seams

1 · sheet metal hem design guide

2 · sheet metal hand hemming tool

3 · seaming process in sheet metal

4 · seam joint in sheet metal

5 · open hem sheet metal

6 · hemmed edge sheet metal

7 · hem300 vs hem305

The Masterplug 13A Weatherproof 4 Socket Extension Lead Box Kit is designed to .

Hemming in sheet metal operations refers to the bending of a sheet metaledge onto itself. It is very similar to edge stitching in clothes. Similar to how an edge stitch strengthens the . See moreThe hemming process can be carried out in one of the following two ways: 1. Die hemming process 2. Roller hemming process See more

A seam is used to connect two metal parts by interlocking the edges of the folded sheet metal parts. The resulting shape may even form a . See more Sheet metal hemming is a type of sheet metal fabrication in which the thin sheet is bent and folded onto itself. The bent can have a closed shape, completely touching the metal surface, or be open with a slight cavity in .

Hemming Procedure. The hemming tool or press brake bends the metal sheet’s edge at a 90º angle and folds the initially bent edge back onto the metal sheet to form a hem. After, clutch the hem to ensure a secure and firm . In sheet metal fabrication, the hemming process involves bending the same part’s sharp edges to form a reinforcement channel. This process is widely used across the automotive and electronics industries. It cuts thin sheet .Applying a hemming procedure on your sheet metal materials can help improve the aesthetics of the final product. Hemming edges are even more tidy compared to the un-hemmed edges. Better-looking edges will increase the overall value .Hemming and seaming are two similar metalworking processes in which a sheet metal edge is rolled over onto itself. Hemming is the process in which the edge is rolled flush to itself, while a .

Hemming is a forming operation in which the edges of the sheet are folded or folded over another part in order to achieve a tight fit. Normally hemming operations are used to connect parts .

Sheet metal hemming is a unique technique that involves folding the edge of sheet metal back on itself to create a double thickness. This process adds durability and strength to the part but eliminates sharp edges. It ensures .

Hemming also allows to join multiple metal sheets which is important for different industrial operations like electronics and construction. What Is the Purpose of Sheet Metal Hems? The main aim of sheet metal hems is to . There are four primary hemming bending solutions designed to accommodate various bending conditions and material requirements in sheet metal fabrication: (1) Flat bottom hemming die: This traditional solution . Welcome to Kreatorzone! On this sheet metal design series you will find the recommended Common sheet metal design guidelines in Hem Feature Guidelines or Hem.hemming process A closed hem A seam. Hemming and seaming are two similar metalworking processes in which a sheet metal edge is rolled over onto itself. Hemming is the process in which the edge is rolled flush to itself, while a seam joins the edges of two materials. [1]Hems are commonly used to reinforce an edge, hide burrs and rough edges, and improve appearance.

Master sheet metal hemming with our comprehensive guide. Explore processes, applications, and best practices for professional-looking metal edges. Improve your fabrication skills today! . Choosing the right materials is . Q2. What is the preferable length of a hem on sheet metal? For open hems, The preferred hem length should be between 0 and 2mm. 16 to 0. It ranges from 5 inches and may vary depending on the sheet metal thickness. Closed hems generally have suggested heights ranging between 0. 24 and 0. 75 inches. Q3. Is it expensive to hem sheet metal parts? Sheet metal is a thin piece of metal between 0.006 and 0.25 inches thick. Sheet metal can be cut, bent, and stretched into various shapes through forming and cutting operations. Common forming operations include bending, deep drawing, and roll forming. Common cutting operations include shearing, blanking, punching, notching, and slitting.It also discusses the steps involved in contour (stretch or shrink) flanging, hole flanging, and hemming and describes the design and operation of press brakes and other bending machines. Topics Bending machines , Bending

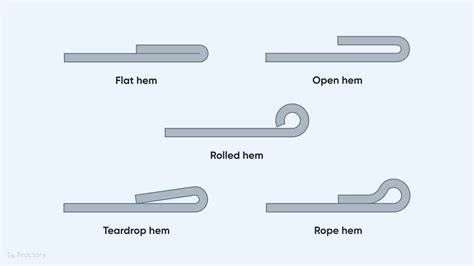

(b) The sheet metal should be notched before starting a curl or hem operation. (c) A wiping operation should generally precede curl or hem operations. (d) Three total operations per curl or hem feature should be required. Hems will be flattened following creation. Following these key points ensures that curls and hems are satisfactorily formed. At Approved Sheet Metal, we rely on our advanced press brake for all custom sheet metal hemming. Here’s a look at the four most common types of sheet metal hems that we use: Table of Contents. 1; 2 When to apply the 4 Common Types of Sheet Metal Hems to your Design. 2.0.1 1. Closed hem. 2.0.2 2. Teardrop hem. 2.0.3 3. Open hem.This process uses rollers to complete the hemming operation. The metal sheet is gradually fed into the rollers, which bend it into the required shape. This method can achieve continuous hemming and is perfect for complex-shaped hemming. However, compared to die hemming, roller hemming can better control the quality and precision of the hemming. .

After folding or hemming a metal sheet, a flattening die or press applies extra pressure to the bend. . Complementing hemming operations. Making edges to enclosures, door panels and automotive parts even. Flattening seams usually created by the joining of a metal sheet pairing. 6. Joggling/Joggle Bending To guarantee a good sheet hemming operation, make sure the metal sheet is horizontal and devoid of contaminants that might impede the process. Then, position the hemming tool to get the desired hem width and angle. Insert the sheet metal into the hemming tool, assembling the edge that requires hemming. 3. Hemming Method Answer: Let’s begin by looking at the hem. While those in the sheet metal trade form dozens of different kinds of hems and seams, most are simply outdated, and only three are in general use. . The “onion” of press brake operation has, at its core, knowledge that is based on basic common sense. Each successive layer of esoteric knowledge .

1. Introduction. Hemming is a kind of sheet metal joining operation that consists of bending outer metal edges onto inner metal. The operation is extensively used in automotive industry due to improved visual quality among the joining operations such as welding, riveting and adhesive bonding.Applications and use cases of sheet metal hem. Sheet metal hemming is used in many industries and plays a pivotal role that is often not seen but vital. Shengen’s expertise allows us to be able to handle the many applications of this technique. Automotive Industry: Its Role and Importance. Sheet metal hemming in the automotive industry is .

types of sheet metal seams

sheet metal hem design guide

Hemming and seaming are two similar metalworking processes in which a sheet metal edge is rolled over onto itself. Hemming is the process in which the edge is rolled flush to itself, while a seam joins the edges of two materials. 1. .

12.Hemming: It is an operation in which the edge of the sheet is folded over itself. This process increases stiffness of the part and eliminate sharp edges. RIT - M.Lakshmanan, AP (S.G)/MECH 70 . (Values from 0.22 to 0.24) .In sheet metal hemming means to fold the metal back on itself. When working with a Brake Press hems are always created in a two step process: Create a bend with Acute Angle Tooling in the metal, 30° is preferable but 45° will work .

sheet metal hand hemming tool

Hemming is a sheet metal forming process in which sheets are joined by bending it usually to 180°. Automotive body panels and automotive parts such as deck-lids, trunk-lids, doors, hoods and tailgates are formed by hemming process. . Improvement of hem quality by optimizing flanging and pre-hemming operations using computer aided die design .

seaming process in sheet metal

Hemming (or flattening) is a great way to finish sharp edges and to strengthen parts after bending sheet metal. +31 573 289 850 Find your local dealer EN NL DE . Alas, a hemming operation will always damage the foil and will leave marking on the product. Classical hemming, roller hemming, robot assisted roller hemming, laser assisted roller hemming and hemming with electromagnetic forming processes are the experimental different approaches utilized for performing sheet metal hemming operations. In FEM simulation of hemming process, three dimensional solid elements, shell elements and their . Columnist Gerald Davis continues a discussion of 3-D CAD and precision sheet metal manufacturing in Part IV of a four-part series. In this installment he focuses on the merits and demerits of hems, jogs, and forming tools. . The initial acute bend in a hemming operation is often completed rather slowly as the workpiece flops and whips during . Secondly, ensure that the tool is properly secured and stable before operating it. Loose or unstable clamping mechanisms can lead to accidents or injuries. It is also important to follow the manufacturer’s instructions and guidelines for safe operation. Common sheet metal design guidelines in Hem Feature Guidelines or Hemming sheet metal process

Abstract. Hemming is a material processing technology widely used in major sectors such as automotive and aerospace industries. As a mechanical joining process, hemming is applied to sheet metal components to build structural assemblies. In conventional hemming methods, dies and presses are used by designing product-specific tooling. In recent years, .

seam joint in sheet metal

Hemming Operation: Perform the final hemming operation by bending the metal to a 180-degree angle. This can be done in one or two stages, depending on the material thickness and the type of hem .Curling sheet metal is the process of adding a hollow, circular roll to the edge of the sheet. The curled edge provides strength to the edge and makes it safe for handling. Curling is different than a tear drop hem because in a curl the edge finishes inside itself, where a . How Does a Metal Hemming Machine Work? The operation of a metal hemming machine involves several key components and steps: Feeding Mechanism: Metal sheets are loaded into the machine using a feeding mechanism. The sheets are typically fed in a sequential manner to ensure precision in the hemming process.

Roll hemming operation can also be divided into several pre-hemming and final hemming process steps. Roll hemming is very flexible to use and tool costs are significantly lower as compared to those of conventional die hemming. . With hemming, the edge of sheet metal is folded so that it becomes flush with the area onto which it’s rolled .

SatelliteSale Weatherproof Junction Box Heavy Duty Enclosure 9x9x4 Inches UV-Rated Thermoplastic Alloy Made in USA

hemming operation in sheet metal|hemmed edge sheet metal