diy cnc laser cutter parts Whether you're constructing a CNC machine, 3D printer, robotics project, or any other mechanical endeavor, the OpenBuilds Custom M5 Low Profile Screws are engineered to excel. The .

Metal Fabricator is a skilled professional who specializes in creating, repairing, and modifying metal components and structures. They work with various types of metals, such as aluminum, steel, and stainless steel for producing items like .

0 · homemade cnc laser cutter

1 · hobby cnc laser cutting machine

2 · cnc laser cutter near me

3 · cnc laser cutter for steel

4 · best value laser engraver cutter

5 · best laser cutting machine for hobbyist

6 · best cnc laser cutting machine

7 · affordable cnc laser cutter

Gas metal arc welding, also known as Metal-Inert Gas (MIG) welding, is a versatile semi-automatic welding technique particularly suited for the welding of thinner materials (<1/2 [13 mm] thick). Welding speeds for GMAW are typically slower for galvanized surfaces.

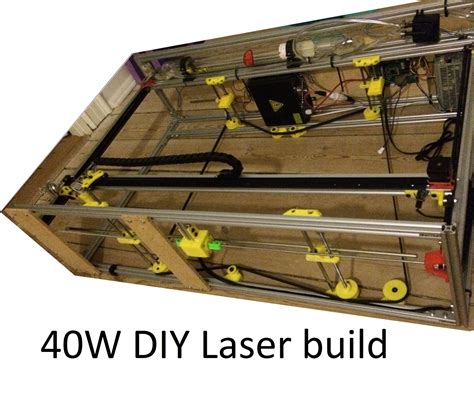

As usual, I've made a complete bill of materials with everything you need to build your own lasercutter. Most of the parts are ordered on aliexpress, some of them on ebay and the rest .The design progress and the built work nearly flawlessly, because the Machine .

This project turns a bad functioning Chinese K40III laser-cutter into a footprint to .Below you will find all of the laser components you will need to start lasing. In a general system for 2 axes you will need one (1) laser tube and laser tube power supply, two (2) mirror mounts, .A simple low-cost XY plane laser engraver/cutter inspired by the Much 4 laser build, with minimal parts and assembly time. Uses standard off the shelf components in almost 90% of the build .Whether you're constructing a CNC machine, 3D printer, robotics project, or any other mechanical endeavor, the OpenBuilds Custom M5 Low Profile Screws are engineered to excel. The .

homemade cnc laser cutter

As usual, I've made a complete bill of materials with everything you need to build your own lasercutter. Most of the parts are ordered on aliexpress, some of them on ebay and the rest you can find in your local DIY-company. The total price of these parts is about €1800.In this tutorial I will show you how I built the simplest CNC machine with minimum parts possible and without using a 3D printer.Below you will find all of the laser components you will need to start lasing. In a general system for 2 axes you will need one (1) laser tube and laser tube power supply, two (2) mirror mounts, three (3) mirrors, one laser nozzle also called laser head .

A simple low-cost XY plane laser engraver/cutter inspired by the Much 4 laser build, with minimal parts and assembly time. Uses standard off the shelf components in almost 90% of the build with the exception of the axes motor and wheel mounts which need to be 3D printed. This article provides a detailed guide on how to build your own laser cutter at home. What's On This Page? Step 1. Design of a Motion Control System. In this stage, you will require the following; RDC6442S-B laser motherboard. Two-phase 57 stepper motor. Leakage protection switch. Grounding resistance. TB6600 driver. A touchscreen. Power switch.Whether you're constructing a CNC machine, 3D printer, robotics project, or any other mechanical endeavor, the OpenBuilds Custom M5 Low Profile Screws are engineered to excel. The precisely cut. Quantity:The design progress and the built work nearly flawlessly, because the Machine is completely designed in Fusion360 and all required parts where milled on my custom CNC-Machine. I decided to make the design of the R-LASER 6020 Open-Source .

With the general DIY idea framework and plan, let's start the 8 steps for building a laser cutter. I will elaborate on the specific making process and the details involved. Step 1. Motion Control System Design. The first step is the motion control system. I use the RDC6442S-B (EC) laser motherboard. In this video I share my process of designing and building a co2 laser cutter using a combination of 'V' & 'T' slotted aluminium profile 3d printed parts. I wanted a larger cutting area than.This project turns a bad functioning Chinese K40III laser-cutter into a footprint to workspace ratio optimized DIY laser-cutter. I will try my best to cover what one could do differently to save money or optimize parts if you're building from scratch.

As usual, I've made a complete bill of materials with everything you need to build your own lasercutter. Most of the parts are ordered on aliexpress, some of them on ebay and the rest you can find in your local DIY-company. The total price of these parts is about €1800.In this tutorial I will show you how I built the simplest CNC machine with minimum parts possible and without using a 3D printer.

Below you will find all of the laser components you will need to start lasing. In a general system for 2 axes you will need one (1) laser tube and laser tube power supply, two (2) mirror mounts, three (3) mirrors, one laser nozzle also called laser head .

A simple low-cost XY plane laser engraver/cutter inspired by the Much 4 laser build, with minimal parts and assembly time. Uses standard off the shelf components in almost 90% of the build with the exception of the axes motor and wheel mounts which need to be 3D printed. This article provides a detailed guide on how to build your own laser cutter at home. What's On This Page? Step 1. Design of a Motion Control System. In this stage, you will require the following; RDC6442S-B laser motherboard. Two-phase 57 stepper motor. Leakage protection switch. Grounding resistance. TB6600 driver. A touchscreen. Power switch.Whether you're constructing a CNC machine, 3D printer, robotics project, or any other mechanical endeavor, the OpenBuilds Custom M5 Low Profile Screws are engineered to excel. The precisely cut. Quantity:

The design progress and the built work nearly flawlessly, because the Machine is completely designed in Fusion360 and all required parts where milled on my custom CNC-Machine. I decided to make the design of the R-LASER 6020 Open-Source . With the general DIY idea framework and plan, let's start the 8 steps for building a laser cutter. I will elaborate on the specific making process and the details involved. Step 1. Motion Control System Design. The first step is the motion control system. I use the RDC6442S-B (EC) laser motherboard. In this video I share my process of designing and building a co2 laser cutter using a combination of 'V' & 'T' slotted aluminium profile 3d printed parts. I wanted a larger cutting area than.

hobby cnc laser cutting machine

cnc laser cutter near me

cnc laser cutter for steel

metal channel fabrication birmingham

Welding sheet metal is one of the manufacturing industry’s basic processes for joining metals. The process usually requires heating the two pieces of sheet metal up to the melting point, then using a torch to weld them together.

diy cnc laser cutter parts|best cnc laser cutting machine