cnc machine g codes pdf GPocket Guide and Reference Charts for CNC Machinists – Made in the U.S.A. – FEATURES Orange Metal Oriole feeder. Holds 1 Jelly Dish + 2 Orange Halves Ready to hang and satisfaction is guaranteed. Dimensions are 7.25"D x 10.6"W x 10"H. Weight is 1.3 lbs MADE IN USA Add Oriole Nectar Here.

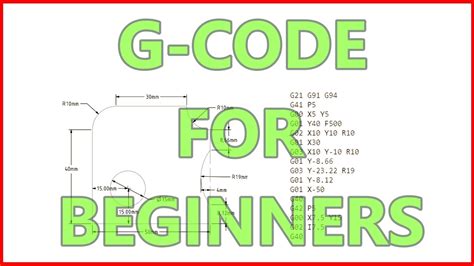

0 · how to understand g code

1 · g code explained with examples

2 · g code commands cheat sheet

3 · free downloadable g code files

4 · complete g code list

5 · cnc mill g code list

6 · cnc machine g code list

7 · cnc g code cheat sheet

Division of Workers’ Compensation 633 17 th Street, Suite 400 . Denver, CO 80202 : 303-318-8700. www .colorado.gov/cdle/dwc. 2020 . claims require payment to the Colorado Uninsured Employer fund. Lump Sums Maximums . Maximum amounts are determined by the date the first lump sum was requested.

how to understand g code

Here are the articles available for maximizing your g-code proficiency and providing you with a little CNC programmer training. Included in nearly every article are examples using our CNC . Here you can check out the list of Haas G Codes and Haas M Codes for CNC Lathes/Mills. Also, Haas and Fanuc G-Code & M-Code PDF files are provided for download. Get up to speed on CNC programming with CNCCookbook's PDF guide. Learn about machine codes, G-code, and more with our comprehensive tutorial.

GPocket Guide and Reference Charts for CNC Machinists – Made in the U.S.A. –

G Code is a special programming language that is interpreted by Computer Numerical Control (CNC) machines to create motion and other tasks. It is a language that can be quite complex .

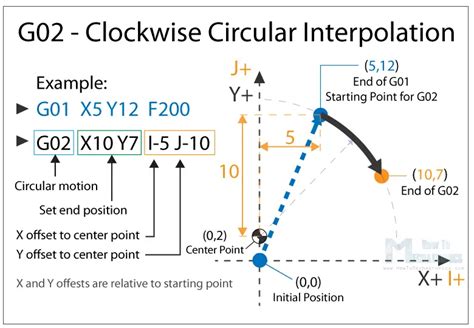

In CNC programming, there are 3 G-codes for selecting a plane during NC programming, which are used to define two axes: X, Y or Z. The plane selection is modal and is valid for everyone .G codes from group B are of "one shot" type (active only in the line in which they are specified). All other G codes are modal (active until another G code of the same group is specified).G53 - Machine coordinate system setting; Mill and Lathe . G54~G59 - Workpiece coordinate system settings #1 t0 #6; Mill and Lathe . G61 - Exact stop check; Mill and Lathe . G65 - .

CNC Programming Reference • G Code • M Code • Auxiliary Commands G Code Canned Cycles - Turning • G70 Finishing • G71 Roughing • G72 Facing • G73 Pattern Repeating • G74 Peck .

G Code is a special programming language that is interpreted by Computer Numerical Control (CNC) machines to create motion and other tasks. It is a language that can be quite complex at times andHere are the articles available for maximizing your g-code proficiency and providing you with a little CNC programmer training. Included in nearly every article are examples using our CNC Programming Software, G-Wizard Editor. Looking to learn CNC G-Code? Need a quick and easy G-Code Tutorial or G-Code Course? Want some easy G-Code Training?

Here you can check out the list of Haas G Codes and Haas M Codes for CNC Lathes/Mills. Also, Haas and Fanuc G-Code & M-Code PDF files are provided for download. Get up to speed on CNC programming with CNCCookbook's PDF guide. Learn about machine codes, G-code, and more with our comprehensive tutorial.GPocket Guide and Reference Charts for CNC Machinists – Made in the U.S.A. –G Code is a special programming language that is interpreted by Computer Numerical Control (CNC) machines to create motion and other tasks. It is a language that can be quite complex at times and can vary from machine to machine. The basics, however, are much simpler than it first appears and for the most part follows an industry adopted standard.

In CNC programming, there are 3 G-codes for selecting a plane during NC programming, which are used to define two axes: X, Y or Z. The plane selection is modal and is valid for everyone until you enter a different circular plane command. The 3 Plane selection G-Codes are: G17 for XY Plane G18 for XZ Plane G19 for YZ PlaneG codes from group B are of "one shot" type (active only in the line in which they are specified). All other G codes are modal (active until another G code of the same group is specified).

g code explained with examples

G53 - Machine coordinate system setting; Mill and Lathe . G54~G59 - Workpiece coordinate system settings #1 t0 #6; Mill and Lathe . G61 - Exact stop check; Mill and Lathe . G65 - Custom macro call; Mill and Lathe . G70 - Finish cycle; Lathe . G71 - Rough turning cycle; Lathe . G72 - Rough facing cycle; Lathe . G73 - Irregular rough turning .CNC Programming Reference • G Code • M Code • Auxiliary Commands G Code Canned Cycles - Turning • G70 Finishing • G71 Roughing • G72 Facing • G73 Pattern Repeating • G74 Peck Drilling • G75 Peck Grooving • G76 Screw Cutting Single Line • G76 Screw Cutting Double Line • G83 Z-axis Peck Drilling • G84 Z-axis TappingG Code is a special programming language that is interpreted by Computer Numerical Control (CNC) machines to create motion and other tasks. It is a language that can be quite complex at times andHere are the articles available for maximizing your g-code proficiency and providing you with a little CNC programmer training. Included in nearly every article are examples using our CNC Programming Software, G-Wizard Editor. Looking to learn CNC G-Code? Need a quick and easy G-Code Tutorial or G-Code Course? Want some easy G-Code Training?

Here you can check out the list of Haas G Codes and Haas M Codes for CNC Lathes/Mills. Also, Haas and Fanuc G-Code & M-Code PDF files are provided for download.

Get up to speed on CNC programming with CNCCookbook's PDF guide. Learn about machine codes, G-code, and more with our comprehensive tutorial.GPocket Guide and Reference Charts for CNC Machinists – Made in the U.S.A. –G Code is a special programming language that is interpreted by Computer Numerical Control (CNC) machines to create motion and other tasks. It is a language that can be quite complex at times and can vary from machine to machine. The basics, however, are much simpler than it first appears and for the most part follows an industry adopted standard.In CNC programming, there are 3 G-codes for selecting a plane during NC programming, which are used to define two axes: X, Y or Z. The plane selection is modal and is valid for everyone until you enter a different circular plane command. The 3 Plane selection G-Codes are: G17 for XY Plane G18 for XZ Plane G19 for YZ Plane

G codes from group B are of "one shot" type (active only in the line in which they are specified). All other G codes are modal (active until another G code of the same group is specified).G53 - Machine coordinate system setting; Mill and Lathe . G54~G59 - Workpiece coordinate system settings #1 t0 #6; Mill and Lathe . G61 - Exact stop check; Mill and Lathe . G65 - Custom macro call; Mill and Lathe . G70 - Finish cycle; Lathe . G71 - Rough turning cycle; Lathe . G72 - Rough facing cycle; Lathe . G73 - Irregular rough turning .

Office Depot WorkPro® 36"W x 18-5/8"D Lateral 2-Drawer File Cabinet, Black File Cabinets Steel frame offers lasting quality.

cnc machine g codes pdf|cnc machine g code list