blank spaces of electrical box osha All pull boxes, junction boxes, and fittings shall be provided with covers identified for the purpose. If metal covers are used, they shall be grounded. In completed installations, each outlet box . Flipkart.com: Buy TREO All Fresh Premier Glass Tiffin Set of 8, Microwave Safe, Dishwasher safe 6 Containers Lunch Box only for Rs. 2499 from Flipkart.com. Only Genuine Products. 30 Day Replacement Guarantee. Free Shipping. Cash On Delivery!

0 · OSHA underground box cover regulations

1 · OSHA switchboard working space requirements

2 · OSHA safety regulations for electrical equipment

3 · OSHA regulations for electrical panels

4 · OSHA regulations for electrical installations

5 · OSHA electrical enclosure regulations

6 · OSHA electrical breaker panels

7 · OSHA electrical breaker diagram

Ever wondered why post-weld heat treatment (PWHT) is essential for welded structures? This process is crucial in reducing residual stress, preventing cracking, and enhancing the durability of welded components. By heating and cooling the welds, PWHT improves mechanical properties and ensures long-term performance.

OSHA underground box cover regulations

Working space. The minimum clear working space in front of electric equipment such as switchboards, control panels, switches, circuit breakers, motor controllers, relays, and similar equipment shall not be less than specified in Table K-2 unless otherwise specified in this subpart.1-800-321-OSHA 1-800-321-6742 www.osha.gov. Federal Government .Permanent ladders or stairways shall be provided to give safe access to the working space around electric equipment installed on platforms, balconies, mezzanine floors, or in attic or roof .All pull boxes, junction boxes, and fittings shall be provided with covers identified for the purpose. If metal covers are used, they shall be grounded. In completed installations, each outlet box .

Insulators and proper grounding help to prevent electrical shocks. Typically, electricity is provided to your building or facility by way of underground or overhead power lines originating from a nearby electrical power plant. The .The following OSHA standards help ensure that electrical panels can be safely used and prevent serious injury. OSHA requires sufficient access and working spaces around all electrical equipment, or panels, serving 600 volts or less. 29 .OSHA and NEC guidelines require clear working space around electric equipment as follows: Minimum clear distances may be 0.7 m (2.5 ft.) for installations built before April 16, 1981. 2. Conditions A, B, and C are as follows:

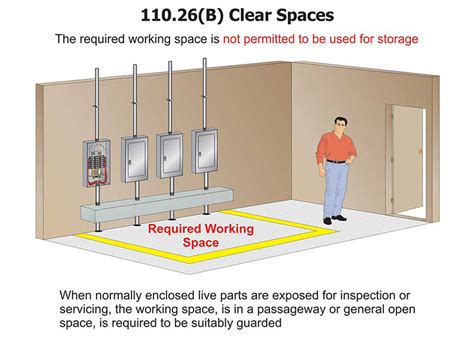

What are the official requirements for electrical panel clearance? Section 1910.303(g)(1) of OSHA mentions how much access and working space is required around electric panels, operating at .OSHA and the National Electrical Code (NEC) specify that electrical panels must have a minimum clearance of 36 inches in depth, 30 inches in width, and 78 inches in height. These dimensions . Question: What would OSHA consider to be a safe distance for setting extra stock or empty containers from any electrical equipment such as ladder cable trays? Reply: 29 CFR . To ensure that an electrical panel can be accessed at all times – during inspection, maintenance or emergency – OSHA has determined that the working space in front of the .

Working space. The minimum clear working space in front of electric equipment such as switchboards, control panels, switches, circuit breakers, motor controllers, relays, and similar equipment shall not be less than specified in Table K-2 unless otherwise specified in this subpart.Permanent ladders or stairways shall be provided to give safe access to the working space around electric equipment installed on platforms, balconies, mezzanine floors, or in attic or roof rooms or spaces.All pull boxes, junction boxes, and fittings shall be provided with covers identified for the purpose. If metal covers are used, they shall be grounded. In completed installations, each outlet box shall have a cover, faceplate, or fixture canopy.

Insulators and proper grounding help to prevent electrical shocks. Typically, electricity is provided to your building or facility by way of underground or overhead power lines originating from a nearby electrical power plant. The power lines .The following OSHA standards help ensure that electrical panels can be safely used and prevent serious injury. OSHA requires sufficient access and working spaces around all electrical equipment, or panels, serving 600 volts or less. 29 CFR 1910.303 (g).

OSHA and NEC guidelines require clear working space around electric equipment as follows: Minimum clear distances may be 0.7 m (2.5 ft.) for installations built before April 16, 1981. 2. Conditions A, B, and C are as follows:

What are the official requirements for electrical panel clearance? Section 1910.303(g)(1) of OSHA mentions how much access and working space is required around electric panels, operating at 600 volts or less to allow ready and safe working. From the standard, it can be deduced that -

OSHA and the National Electrical Code (NEC) specify that electrical panels must have a minimum clearance of 36 inches in depth, 30 inches in width, and 78 inches in height. These dimensions ensure sufficient space for workers to safely and efficiently perform maintenance tasks.

Question: What would OSHA consider to be a safe distance for setting extra stock or empty containers from any electrical equipment such as ladder cable trays? Reply: 29 CFR 1910.303(g)(2)(ii) and 1910.303(h)(2)(ii) address the protection of electric equipment that may be exposed to physical damage. To ensure that an electrical panel can be accessed at all times – during inspection, maintenance or emergency – OSHA has determined that the working space in front of the equipment must be at least 30-inches wide (or the width of the equipment).Working space. The minimum clear working space in front of electric equipment such as switchboards, control panels, switches, circuit breakers, motor controllers, relays, and similar equipment shall not be less than specified in Table K-2 unless otherwise specified in this subpart.Permanent ladders or stairways shall be provided to give safe access to the working space around electric equipment installed on platforms, balconies, mezzanine floors, or in attic or roof rooms or spaces.

All pull boxes, junction boxes, and fittings shall be provided with covers identified for the purpose. If metal covers are used, they shall be grounded. In completed installations, each outlet box shall have a cover, faceplate, or fixture canopy.

OSHA switchboard working space requirements

Insulators and proper grounding help to prevent electrical shocks. Typically, electricity is provided to your building or facility by way of underground or overhead power lines originating from a nearby electrical power plant. The power lines .The following OSHA standards help ensure that electrical panels can be safely used and prevent serious injury. OSHA requires sufficient access and working spaces around all electrical equipment, or panels, serving 600 volts or less. 29 CFR 1910.303 (g).

OSHA and NEC guidelines require clear working space around electric equipment as follows: Minimum clear distances may be 0.7 m (2.5 ft.) for installations built before April 16, 1981. 2. Conditions A, B, and C are as follows:What are the official requirements for electrical panel clearance? Section 1910.303(g)(1) of OSHA mentions how much access and working space is required around electric panels, operating at 600 volts or less to allow ready and safe working. From the standard, it can be deduced that -OSHA and the National Electrical Code (NEC) specify that electrical panels must have a minimum clearance of 36 inches in depth, 30 inches in width, and 78 inches in height. These dimensions ensure sufficient space for workers to safely and efficiently perform maintenance tasks. Question: What would OSHA consider to be a safe distance for setting extra stock or empty containers from any electrical equipment such as ladder cable trays? Reply: 29 CFR 1910.303(g)(2)(ii) and 1910.303(h)(2)(ii) address the protection of electric equipment that may be exposed to physical damage.

metal fabrication wisconsin rapids

EMP Die Casting offers a good range of quality aluminium transmission housing. Suitable for manufacturing large-scale die castings with irregular shapes and more complex shapes. Find yourself the fitting transmission extension housing now.

blank spaces of electrical box osha|OSHA electrical breaker panels