16 gauge sheet metal thickness tolerance For cold rolled gauges 4 – 10, tolerances shown are for widths over 48” through 72”. Tolerances for HR and P&O gauges 4 – 18 are for widths over 40” through 48”; all other gauges, over 15” .

$226.99

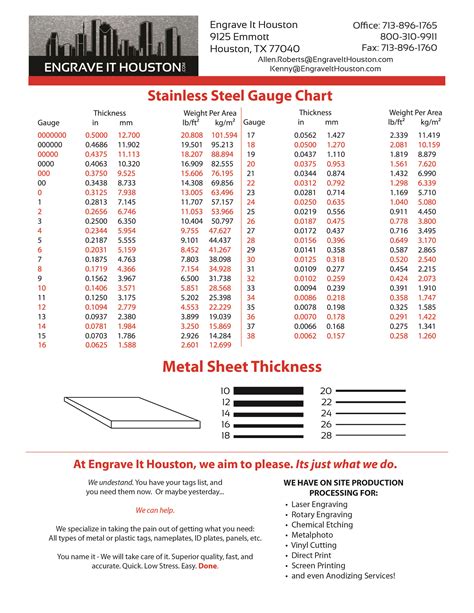

0 · stainless steel gauge chart

1 · sheet metal gauge chart mm

2 · how thick is 16ga steel

3 · gauge to millimeter chart

4 · galvanized steel gauge thickness chart

5 · galvanized sheet metal thickness chart

6 · conversion chart gauge to inches

7 · 16 gauge vs 20 thickness

CRAFTSMAN TRADESTACK Tool Box, Waterproof Indoor/Outdoor, Stackable Tool Storage, Lockable, 21 Inch (CMST21430)

Sheet Metal Guage Tolerances. During the rolling process the rollers bow slightly, which results in the sheets being thinner on the edges. The tolerances in the table and attachments reflect current manufacturing practices and commercial standards and are not representative of the .The following charts give typical ASTM and ANSI steel sheet mechanical tolerance .

Tolerances: Sheet metal tolerances should not be tighter than necessary to make . The following charts give typical ASTM and ANSI steel sheet mechanical tolerance . For example, a 16-gauge cold-rolled steel sheet may have a stated thickness of 0.057", but the actual thickness can be around 0.056". These .

For cold rolled gauges 4 – 10, tolerances shown are for widths over 48” through 72”. Tolerances for HR and P&O gauges 4 – 18 are for widths over 40” through 48”; all other gauges, over 15” .Hot rolled P&O gages 4 through 18 - tolerances shown for widths over 40" to 48" inclusive. All other gages over 15" to 72" inclusive.Weight equivalents based on density of .2904 lb. per cubic inch. Gauges 10, 11, 12 - tolerances shown are for widths over 40" to 60" inclusive. All other gauges -- tolerances shown are for .

We work with nominal thicknesses, so it's important to know the thickness tolerance on the material you chose, in order to know if the final product will be suitable for your application. It's also important when working with sheet metal .Sheet metal thickness tolerances for Austenitic, Ferritic and Martensitic Stainless steels. You can use this sheet metal data table for all the common commercial grades of stainless steel such . Tolerances: Sheet metal tolerances should not be tighter than necessary to make the part functional. Tight tolerances raise the cost of manufacturing significantly. Practical .

AISI Thickness Tolerance Ranges Galvanized Steel Sheets Thinkness. inches lbs. per sq.ft. Thinkness. . 16 .0635 .0695 .0575 2.65625 27 .0202 .0232 . Weight equivalents based on .

stainless steel gauge chart

Sheet Metal Guage Tolerances. During the rolling process the rollers bow slightly, which results in the sheets being thinner on the edges. The tolerances in the table and attachments reflect current manufacturing practices and commercial standards and are not representative of the Manufacturer's Standard Gauge, which has no inherent tolerances.The following charts give typical ASTM and ANSI steel sheet mechanical tolerance ranges. Carbon Steel Sheets. Galvanized Steel Sheets. For example, a 16-gauge cold-rolled steel sheet may have a stated thickness of 0.057", but the actual thickness can be around 0.056". These variations can impact tolerances, as a portion of the allowable tolerance is consumed just .For cold rolled gauges 4 – 10, tolerances shown are for widths over 48” through 72”. Tolerances for HR and P&O gauges 4 – 18 are for widths over 40” through 48”; all other gauges, over 15” through 72”.

Hot rolled P&O gages 4 through 18 - tolerances shown for widths over 40" to 48" inclusive. All other gages over 15" to 72" inclusive.Weight equivalents based on density of .2904 lb. per cubic inch. Gauges 10, 11, 12 - tolerances shown are for widths over 40" to 60" inclusive. All other gauges -- tolerances shown are for width over 32" to 60" inclusive.

We work with nominal thicknesses, so it's important to know the thickness tolerance on the material you chose, in order to know if the final product will be suitable for your application. It's also important when working with sheet metal that you factor in finish tolerances.

Sheet metal thickness tolerances for Austenitic, Ferritic and Martensitic Stainless steels. You can use this sheet metal data table for all the common commercial grades of stainless steel such as 304, 316 and 430. These are the most common grades asked for by our customers when wanting sheet metal fabrications.Tolerances: Sheet metal tolerances should not be tighter than necessary to make the part functional. Tight tolerances raise the cost of manufacturing significantly. Practical tolerances vary according to the design requirements. Tolerances of +/- .010 should be considered minimum. Linear tolerances should be held as loose as possible.AISI Thickness Tolerance Ranges Galvanized Steel Sheets Thinkness. inches lbs. per sq.ft. Thinkness. . 16 .0635 .0695 .0575 2.65625 27 .0202 .0232 . Weight equivalents based on density of .2904 lb. per cubic inch Gages 10, 11, 12 – tolerances shown are for widths over 40” to 60” inclusive All other gages – tolerances shown are for .Sheet Metal Guage Tolerances. During the rolling process the rollers bow slightly, which results in the sheets being thinner on the edges. The tolerances in the table and attachments reflect current manufacturing practices and commercial standards and are not representative of the Manufacturer's Standard Gauge, which has no inherent tolerances.

The following charts give typical ASTM and ANSI steel sheet mechanical tolerance ranges. Carbon Steel Sheets. Galvanized Steel Sheets. For example, a 16-gauge cold-rolled steel sheet may have a stated thickness of 0.057", but the actual thickness can be around 0.056". These variations can impact tolerances, as a portion of the allowable tolerance is consumed just .For cold rolled gauges 4 – 10, tolerances shown are for widths over 48” through 72”. Tolerances for HR and P&O gauges 4 – 18 are for widths over 40” through 48”; all other gauges, over 15” through 72”.Hot rolled P&O gages 4 through 18 - tolerances shown for widths over 40" to 48" inclusive. All other gages over 15" to 72" inclusive.

Weight equivalents based on density of .2904 lb. per cubic inch. Gauges 10, 11, 12 - tolerances shown are for widths over 40" to 60" inclusive. All other gauges -- tolerances shown are for width over 32" to 60" inclusive.We work with nominal thicknesses, so it's important to know the thickness tolerance on the material you chose, in order to know if the final product will be suitable for your application. It's also important when working with sheet metal that you factor in finish tolerances.

Sheet metal thickness tolerances for Austenitic, Ferritic and Martensitic Stainless steels. You can use this sheet metal data table for all the common commercial grades of stainless steel such as 304, 316 and 430. These are the most common grades asked for by our customers when wanting sheet metal fabrications.Tolerances: Sheet metal tolerances should not be tighter than necessary to make the part functional. Tight tolerances raise the cost of manufacturing significantly. Practical tolerances vary according to the design requirements. Tolerances of +/- .010 should be considered minimum. Linear tolerances should be held as loose as possible.

sheet metal gauge chart mm

$14.19

16 gauge sheet metal thickness tolerance|conversion chart gauge to inches