tig settings for sheet metal Preventing burn-through and warping when welding sheet metal is all about . Learn how to hide an unsightly electrical box outside your home with these simple tips. Our step-by-step guide will show you how to choose the right materials, install a cover, .

0 · welding tig settings

1 · tig welding settings sheet metal

2 · tig welding for sheet metal

3 · tig setting sheet metal

4 · pulse tig sheet metal

5 · milling tig sheet metal

6 · miller tig welding settings

7 · how to tig sheet metal

Sheet metal enclosures can be designed to meet the requirements of NEMA Types 1, 2, 4, 4X and 5. However, if your enclosure requires immersion in water, this is not the best choice for you. Here are some guidelines: NEMA Type 1: We recommend a simple two-piece enclosure style that is fully covered on the top of the case.

For the best appearance, highest quality and leak free welds on aluminum, AC TIG welding is the process of choice. The primary gas used is argon and in some applications on thick aluminum when additional penetration is needed an argon/helium mixture or pure helium is used.Preventing burn-through and warping when welding sheet metal is all about . Preventing burn-through and warping when welding sheet metal is all about controlling the heat. Choose the right welding process and filler metal, and follow these .Polarity – This is simple. Use DCEN (DC Electrode Negative is also referred to as Straight Polarity or simply DC-) when welding steel and stainless steel. Use AC (Alternating Current) when welding aluminum and magnesium. Don’t ever use .

TIG (Tungsten Inert Gas) welding excels at joining thin sheet metal. It provides superior control, minimal distortion, and clean, strong welds. By using a non-consumable tungsten electrode and inert gas shielding, TIG allows for precise . Did you know that TIG welding is the best option for sheet metal? The biggest problem any welder is going to face when it comes to sheet metal is the heat in.

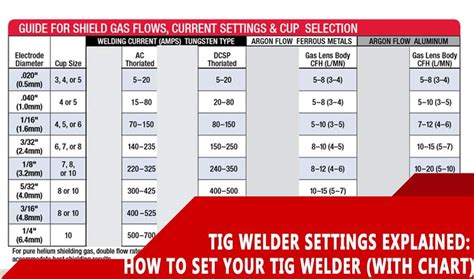

Setting up the TIG welding machine for sheet metal involves a systematic approach to dialing in the appropriate parameters. Begin by selecting the correct tungsten electrode size based on the material thickness and type. A TIG Welding Settings Chart is an indispensable tool for welders, offering a roadmap to the ideal settings for various materials and thicknesses. Let’s dive into how travel speed and temperature control work in harmony to .

sydney laser cut metal cutting & fabrication

TIG welders can be used to weld steel, stainless steel, chromoly, aluminum, nickel alloys, magnesium, copper, brass, bronze and even gold. The TIG process can be used to weld everything from bike frames to door handles . Understanding the Basics of TIG Welding Steel Settings. A. The Role of Current Type in TIG Welding. AC vs. DC Current: The choice between alternating current (AC) and direct current (DC) plays a pivotal role in TIG .Below is a quick guide for selecting the right items for your tig welding. This is basic set up information, if you have questions please leave it in the comments sections. Shielding Gas – 90% of applications can be done with 100% argon. . TIG Welding Chart Based on Material and Shielding Gas. The amperage required when TIG welding is highly affected by the type of metal you are working with and how thick that metal is. The three main types of metals .

There is no "Volt" setting for TIG. When I have a remote control, like a pedal, I use 65A as max. Usually a 3/32" tungsten. Cup doesn't matter much indoors. . Oh, and 16 ga. is not "thin" sheet metal. Steve S. Top. blaz. blaz; Workhorse; Posts: 52. Joined: Fri Feb 01, 2013 4:08 am. Thu May 30, 2013 4:33 am. For thin sheet metal welding it can be 30 ampere while for thicker (e.g. 1/8” square groove weld)- it can go up to 220 ampere for example. GMAW-S gives low heat and makes it easy to use in all positions on sheet metal, low carbon steel, low alloy steel, and stainless steel sheet metal from 25 gauge (0.02 inch or 0.5 mm) to 12 gauge (0.1 inches or 2.6 mm). In this video I show how to set up and tig weld thin metal. There are a lot of different steps to take and I try to make it as easy as possible. From how to . TIG Welding thin stainless steel sheets or tube is a challenging task that requires very high welder skills- both manual as well as equipment setup. . welding stainless steel (thin sheet metal or tubing) has following challenges: High chances of burn-through due to small material thickness . (Amperage). 40 to 60 ampere is the right when .

In contrast to manual arc welding and TIG welding, MIG/MAG systems require only two adjustments to set up. . Below is the MIG Welding Aluminum Sheet Metal Settings Chart which displays the recommended settings for welding aluminum sheet metal. Aluminum is a unique material to weld and requires special settings compared to other metals.

3. Adjust Your Torch Angle. Changing the torch angle when MIG welding goes a long way to preventing burn-throughs. Make sure you adjust the angle to shorten the distance between the tip and the metal, no matter the welding position you work in.This will make the arc more stable, giving you more control over the weld and lessening the chance of burn-through.

Settings for MIG welding sheet metal(14 gauge) steel? . I actually welded some iron boxes at work a few weeks back that was 11 or 12 to 14 gauge sheet metal. I wasn’t allowed much burn through on the back, just a light sugaring if I could get it. I was running about 16.5 volts and around 110 on the wire speed. . Tig Teamwork upvotes . https://www.proshaper.comOur Amazon Storefront:https://www.amazon.com/shop/proshaperIn this video Wray shows the steel sheet metal butt welding results after.Hello everyone.It is not easy to weld thin sheet metal with a general welding machine.Therefore, there are many cases of using a cold welding machine when we. MIG Welding Sheet Metal Settings. Achieving optimal MIG welding settings for sheet metal hinges on precise control over voltage and wire feed speed. For thin sheet metals, lower voltage settings are typically recommended to .

The wire feed speed (WFS) settings control the pace at which the electrode is fed into the weld, ensuring enough weld metal is provided for the join. Advantages MIG welding is generally faster than TIG welding.

1 A 1.6mm tungsten is OK down to about 30 amps. It can be used on thinner material if the tip is kept very sharp. Reduce the amps a little if using a 1.0mm tungsten. 2 2mm is the transition between 1.0mm and 1.6mm filler rod. The larger filler rod cools the weld pool more than the smaller rod so you might add about 5 amps if using 1.6mm filler rod. I'm trying to butt weld some 20 gauge cold rolled sheet metal for the Datsun and not having much luck. This is my first attempt at tig plus I'm old, half blind and a slow learner so bear with me. I am using an Everlast 211si welder. I have . I am new to welding and am trying to butt weld 22 guage mild steel sheet together I am using a miller dynasty 200 dx tig tried 1/8 ceriated electrode 3/32 lath electrode with argon flow at 20 cfh settings are dc with current ranging from 10 to 50 amps the butt joints are fit fairly tight but you can see light through the gap my problem is the edges of the steel melt away and .

For sheet metal what is the welding current needed. i see some machines with low of 15 amp, 20 amp 30 amp. . arc length etc where as stick and tig are constant current so when you set the current you know that is what you are getting. Best bet is to play about with the settings and see what works. . I have never successfully used less than .

When welding cold rolled mild steel sheet metal you must use tig filler wire reason being the sheet metal has not been killed so it has oxygen in it ,,, the wire for tig is triple de-oxidized and also has a deoxidizer in it ,,, no wire you will get porosity and brittle welds ,,,, do not use brake cleaner it creates some nasty chemical when . For most TIG welding, 100% argon will serve you fine. In my two decades of TIG welding, I’ve only used other shielding gas a handful of times for specific projects. Selecting the Right Filler Metal . The filler metal used in TIG welding is long rods of metal that you dip into the weld puddle adding material to the weld.

Another rule of thumb for tig welding sheet metal thicknesses is try not to use a filler rod that is thicker than the metal you are welding. but that is only a guideline. I used 1/16" (1.6m) 4043 rod for this outside corner joint in .040" and it worked out ok. . One ac balance setting will not work across the board. You can, if you have a machine that is capable of it, use a pulse tig setting on your sheet metal. Using pulse tig helps to minimize how much heat is being put into the metal as the amps decrease and then . Spot welding is typically used to join two sheets of sheet metal, welded wire mesh or wire mesh, or any combination thereof. . In certain scenarios, it may be easier to be able to adjust the settings of the TIG welder to produce the spot welds instead of getting out, switching the TIG welder out for a spot welder, and repositioning before .

You’ll also need to learn the TIG power supply features and TIG welding machine settings. . so the electricity flows from the metal to the TIG torch. . we focus on the side of the heat that’s most concentrated when working with sheet metal. So, D/C power works with heat in welding the same way it does when you move water from a pitcher .

Any tips on very then sheet metal welding or settings? Argon flow rates, why my flame is hunting at low amps. . Tig has a tendency to allow an amateur to hold the arc to long in one spot dumping to much heat into the base metal. No Bueno on body work. Like the other comment said tack every 6 inches min, let cool completely and repeat. Also .

Primeweld tig 225x Setting .In this video we go over the basic setting you will need to get started on the tig 225x. or any other inverter welder.If you foun.

16 guage sheet metal, volt setting, tungsten size and cup size? Is there a reference chart for all this? Thanks guys & gals! Top. Otto Nobedder; . I weld 16 ga stainless frequently. There is no "Volt" setting for TIG. When I have a remote control, like a pedal, I use 65A as max. Usually a 3/32" tungsten. Cup doesn't matter much indoors. I . Features 4 levels of current flow settings; . For sheet metal, TIG welding often provides the best results. I remember working on a vintage car restoration, where the sheet metal required a lot of detailed welding. After struggling with a MIG welder, I switched to a TIG machine and was amazed at the difference. .

welding tig settings

Outdoor floor box with stainless cover; Push Button Open; Fully IP66 rated water proof (when in closed position). Includes wrench for inside wire connections.

tig settings for sheet metal|tig welding settings sheet metal