sheet metal flat pattern development Downloads - Plate 'n' Sheet - Software for flat pattern development of commonly . Metal boxes are a good choice for high-current applications, while plastic boxes are more suitable for corrosive or damp environments. Plastic electrical boxes are the most common type of electrical box. They are made from a variety of .

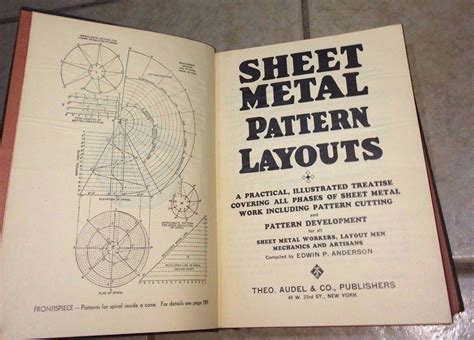

0 · sheet metal pattern layouts pdf

1 · sheet metal pattern layout methods

2 · sheet metal layout software free

3 · sheet metal layout pdf

4 · sheet metal fittings layout drawing

5 · sheet metal development drawing pdf

6 · free sheet metal layout patterns

7 · free sheet metal layout books

$14.48

Unfolding software for commonly used shapes used in Metals, Plastics and Insulation Industries. Stand-alone program, does not require additional software. Print or Plot the pattern layout. .

Print or Plot the pattern layout. . Sheet Metal Transition Software : Pipework .

sheet metal pattern layouts pdf

sheet metal pattern layout methods

Purchasing Details - Plate 'n' Sheet - Software for flat pattern development of .Downloads - Plate 'n' Sheet - Software for flat pattern development of commonly .Enquiry Form - Plate 'n' Sheet - Software for flat pattern development of commonly .Contact Details - Plate 'n' Sheet - Software for flat pattern development of commonly .

Upgrade - Plate 'n' Sheet - Software for flat pattern development of commonly .List of Shapes - Plate 'n' Sheet - Software for flat pattern development of commonly .Plate 'n' Sheet Development Software . System Requirements. Plate n Sheet .Plate 'n' Sheet Professional Version 4, Feature List. Overview. . Pattern .

Plate 'n 'Sheet Software products are provided as evaluation versions for .The Online Pattern development unfolder tool for sheet metal fabrication! We help sheet metal fabrication workers, engineers, and workshops draw and calculate patterns in minutes on line. lots of patterns available, easy to use, on any . K Factor in sheet metal bending is a constant used to calculate sheet metal flat length or Flat-pattern. Mathematically k factor value is equal to the ratio of position of the .

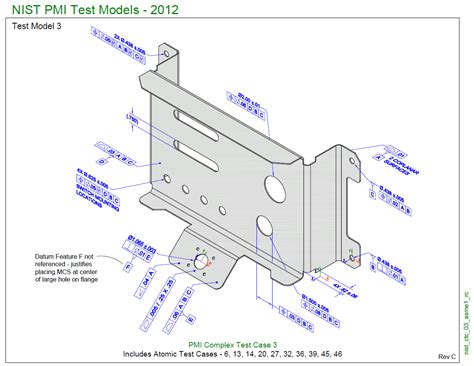

Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a .Plate’n’Sheet® is the industry's leading unfolding, flat pattern development software for commonly used shapes used in the metal, plastics, HVAC and insulation industries. Plate’n’Sheet is .Transition Calculator is used to generate Flat Pattern Layout Markings or Fabrication Layout Markings of Rectangular to Round Transition or Square to Round Transition, Round to .

Sheet Metal Flat Pattern Calculator. When sheet metal is bent, the inside bending surface is compressed. Whereas the outer surface is stretched. As a result, overall sheet length increases. You can use this sheet metal flat pattern .Use the Flat Pattern tool to create a flat pattern that you can use to create drawings of a sheet metal component for manufacturing in Fusion. A Flat Pattern is the shape of the sheet metal component before it is formed.Plate ‘n’ Sheet auto-generates sheet metal drawings so that you can fabricate your sheet metal shape without learning CAD or creating a flat template by hand. Discover the top 5 free CAD software for sheet metal design, including FreeCAD, Onshape, and Fusion 360. Unleash your creativity with these powerful, easy-to-use programs that streamline your sheet metal projects.

sheet metal layout software free

Flat Pattern (FP): It is the planar drawing of the blank required to form the desired sheet metal component. Flat Pattern Development (FPD): It is the process of determining flat pattern for a sheet metal component corresponding to its neutral surface. The neutral surface is the surface within the sheet that is parallel to the inner andFlat Pattern Making or Flat Surface Development process is very useful while working in the sheet metal Industry and Equipment fabrication Industry. In Sheet Metal or Fabrication Industry Flat Pattern making is useful for forming various shapes such as Conical Shapes, Box Shapes, Pipe Shapes, Transition Shapes such as Square to Round or Round .Use the elbow rule (# of pcs × 2 − 2) to find the number of gores.For our example, it is 4 × 2 − 2 = 6.Each end piece is made up of 1 gore and each middle piece is made up of two gores.; Use the angle of the elbow divided by the number of gores to find the miter angle. In our case, 90° ÷ 6 = 15°. Now that we know the miter angle is 15°, we can use an end gore and lay it out similar .Development Cord Length has calculated by this calculator and Denoted By X1 and X2. This development Angle is used to layout cone fabrication layout markings or Flat Pattern Markings. Refer to Standard Image for understanding these dimensions at Output sections. What are Types of Cone Flat Pattern Layout Available with this Cone Calculator

Software Development • Mobile App • Testing; inar On Latest Trends in Digital Marketing 2022; . use the Tools tab Flat groupFlatten command to produce a flat pattern in the same file as the formed sheet metal item. A Flat Pattern feature is added to the PathFinder tab when you flatten a sheet metal part with the Flatten command.This will generate the pattern for the sheet metal shape based on your defined parameters. You can switch between the 3D model view and the pattern view as needed. . The shapes may be viewed as either a 3D model or as a flat pattern at any stage of the process. Tools are supplied to zoom in or out to see the shape in detail. If it is being .

Layout Drafting & Pattern Making for Insulators Page 2 Preface This book has been prepared as a text for use in Heat and Frost Insulator apprenticeship classes. It explains basic methods of drawing patterns for developing sheet metal and other types of protective covers commonly produced for wrap over insulation. The book does not attempt to teach

Sheet metal fabrication requires flat pattern development to determine blank shapes and sizes. For a 2D design, bend allowances resulting from metal stretching at bends must be accommodated. In addition to bend allowances, flat patterning for a 3D design involves unfolding of walls and mapping of features such as slots, cutouts, etc., onto . Hi. I'm having an issue with a flat pattern not generating. After a quick check of the common reasons for failure, the material type and thickness seem to match the sheet metal default being used. The design intent got pretty murky through the development of the assmbly, and I just need a flat pattern to cut this part "Back plate_sheave box.ipt".This development Angle is used to layout cone fabrication layout markings or Flat Pattern Markings. Refer to Standard Image for understanding these dimensions at Output sections. Development Cord Length (X1 and X2) : Development Cord Length has calculated by this calculator and Denoted By X1 and X2.Welcome to dxfcreator.com. The website for online creation of flat pattern sheetmetal parts and generation of DXF files of these sheetmetal parts, all this without using CAD software and within a very short space of time. A preview of the sheet metal will be displayed once the requested parameters have been entered.

Pt1. Introduction - https://youtu.be/VPwwbUz7p34Pt2. Square Based Pyramid Development - https://youtu.be/3h9uDY67NQ8Pt3. Frustrum of a Cone Development - htt. Hi, I have a sheet metal part from CATIA that can be flattened in a CATIA sheet metal environment. I am trying to do a similar thing in Inventor but somehow could not figure out this. please assist, is it possible to unfold or make a flat pattern from uneven sheet metal components, if yes then how? I am sharing the component file if you need it! Discover the top 5 free CAD software for sheet metal design, including FreeCAD, Onshape, and Fusion 360. . Another reason for this is that most metalworking schools still teach students how to design flat patterns themselves, calculate bend shortenings based on material thickness, and k-factors. . You can actively contribute to the .

Flat Back Elbow. 3. Tee on a Taper. 4. 4 Piece Transition. 5. Square to Round Elbow-3 Piece. 6. Round Tapering Elbow-3 Piece. 7. Multi-piece Tapering Elbows-4 or More Pieces. Pattern Development: Sheet Metal Level 4 . Advanced Pattern Development By this time in your training, we are looking at advanced pattern development of various fittings. .

sheet metal layout pdf

Take a look at how we got started, before you can begin to layout your pattern you have to find all your true lengths. The only way you can see a true length line is perpendicular to its plane, the best way to see the true . The flat pattern development of sheet metal components is a prerequisite for sheet metal fabrication. The conventional graphic solution or the analytical method carried out manually is laborious .Pattern Development: Sheet Metal Level 1. Triangulation When we looked at both parallel line and radial line pattern development, we saw fairly simple and limited layout process. We have conditions that must be met in order to use them. Triangulation is the process used when nothing else works. There are very few conditions in which .Sheet metal, flat pattern, and adding tabs. How do I make these tabs visible? . /r/3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices. Members Online. Help in slicer settings

From here, we perform different calculations, depending on the flat-blank development used. Using the first method, we develop the flat blank by adding the two legs of the bend and the bend allowance. Flat-blank Calculation Calculated flat-blank length = Leg + Leg + BA Calculated flat-blank length = 1.000 + 1.000 + 1.010Sheet Metal Flat Pattern in wrong orientation . Hi guys! I have designed a couple of sheet metal parts, and i am making flat patterns that i am exporting to use on my plasma cutter. . /r/3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices. The flat pattern development of sheet metal components is a prerequisite for sheet metal fabrication. The conventional graphic solution or the analytical method carried out manually is laborious, time-consuming, and lacks accuracy. The feature-based flattening could help to achieve the objective of automatic pattern generation; however, it is .To meet unique sheet metal design challenges like manufac-turability, Solid Edge streamli-nes the entire sheet metal product development process, from CAD design through flat pattern and drawing development. Unlike general-purpose CAD tools, Solid Edge includes sheet metal-specific features like emboss, dimple, drawn cutout,

Flat pattern development of sheet metal components is a prerequisite for sheet metal fabrication and it also facilitates development of process plans. Commercial softwares for flat pattern development are too expensive and they often require a 3-D model of the component. In fact, most of the component drawings exist as orthographic projections .The goal of this manual is to help you gain an understanding of precision sheet metal layout and show you how to do flat pattern development while becoming more efficient with math in the shop. Therefore the first part of this manual deals strictly with math that is related to sheet metal development. Geometry, Algebra and Trigonometry will all .

Pattern Development: Sheet Metal Level 1. Parallel Line Pattern Development. 15 Equal Diameter 90 Degree Tee We can start to take some short-cuts in our drawing. Instead of drawing a full plan view, we will use profiles. You can always go back to drawing the full plan view! . Flat, level. × Close definition. an intersection of 2 pieces- an .The website for online development of sheetmetal parts and generation of DXF files of these sheetmetal parts, possible without using CAD software and within a very short space of time. A preview of the sheet metal will be displayed once the requested parameters have been entered. . development, flat pattern, dxf, cad, online, ducting, piping .

sheet metal fittings layout drawing

sheet metal development drawing pdf

free sheet metal layout patterns

Ordering a custom-made aluminum tray or box out of aluminum sheet metal is easy as 1,2,3... Once you have your measurements ready and you know what kind of shape you would prefer it is as easy as ordering something to eat.

sheet metal flat pattern development|free sheet metal layout books