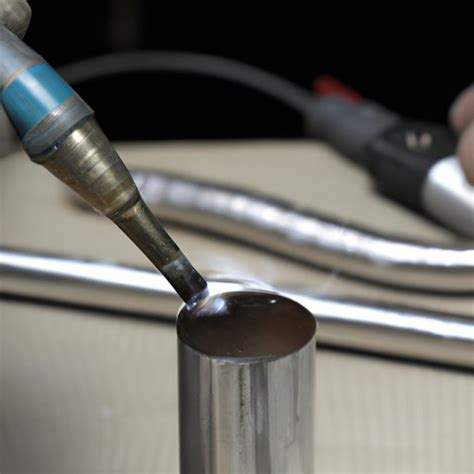

brazing steel sheet metal Brazing steel with a propane torch involves cleaning joint surfaces, applying flux, heating the joint with the torch until red-hot, and feeding a brazing filler rod into the joint. The filler melts and flows into the joint, forming a strong . Whether you own a brick ranch with metal roof or you want to re-roof your brick colonial or Victorian home with a metal roof, you can find a metal roof type that looks great but may end up paying more than you’d like.

0 · metal brazing pros and cons

1 · how to braze metal together

2 · how strong is brazing

3 · can you braze galvanized steel

4 · brazing strength vs welding

5 · brazing steel with propane torch

6 · brazing stainless steel with propane

7 · brazing stainless steel sheet metal

Welcome to West Coast Custom Metal Design, Inc! We work with government, industrial and commercial clients. If your steel, stainless steel, or aluminum project requires high quality design and fabrication, call us! We have over 20 years of experience with metal fabrication of all types.

Brazing is the process of joining two independent pieces of metal to form one strong load-bearing joint. Brazing is similar to soldering, but at higher temperatures. Use the right brazing rod material for the metal used in your . Brazing is a joining process where melting a filler metal into the joint creates permanent solid bonds. Brazing requires a small joint spacing to allow capillary action to draw the molten filler metal into the joint. Both welding and . Brazing steel with a propane torch involves cleaning joint surfaces, applying flux, heating the joint with the torch until red-hot, and feeding a brazing filler rod into the joint. The filler melts and flows into the joint, forming a strong . Brazing is a high-temperature joining process where a filler metal is heated to a temperature typically exceeding 450°C (842°F). This temperature is carefully selected to be above the liquidus point of the filler metal but below .

To braze weld sheet metal, first, clean the metal surfaces, apply flux, heat the metal, and then apply the brazing rod. Braze welding can be done with a torch, furnace, or induction heater. It provides strong, durable joints that . Learn how to braze steel like a pro with this comprehensive guide that covers everything from fluxing and flame adjustment to proper post-braze cleaning.Brazing is the process of joining two independent pieces of metal to form one strong load-bearing joint. Brazing is similar to soldering, but at higher temperatures. Use the right brazing rod material for the metal used in your project. Brazing is a joining process where melting a filler metal into the joint creates permanent solid bonds. Brazing requires a small joint spacing to allow capillary action to draw the molten filler metal into the joint. Both welding and brazing utilize heat to join materials, but the essential difference is the temperature.

Brazing steel with a propane torch involves cleaning joint surfaces, applying flux, heating the joint with the torch until red-hot, and feeding a brazing filler rod into the joint. The filler melts and flows into the joint, forming a strong bond when cooled. Brazing is a high-temperature joining process where a filler metal is heated to a temperature typically exceeding 450°C (842°F). This temperature is carefully selected to be above the liquidus point of the filler metal but below the solidus . To braze weld sheet metal, first, clean the metal surfaces, apply flux, heat the metal, and then apply the brazing rod. Braze welding can be done with a torch, furnace, or induction heater. It provides strong, durable joints that are resistant to corrosion and wear.

Learn how to easily braze steel, iron, brass, bronze, or copper using the supplies shown in this video that yield excellent results! You'll be able to make m.Learn how to braze metal using a blow torch and brazing rod with these step by step instructions. This project features clear, animated illustrations and diagrams showing you every step you need to make a solid join with a blow torch or brazing rod.Use these easy steps and procedures on how to braze metal to create solid joints like a pro: Scrub the metal surface using a wire brush or emery cloth. Then use soapy water or a degreaser to clean the metal surfaces. Place the metal in an appropriate position for .

In this guide, we will explore the steps and materials needed to braze steel to steel effectively, ensuring a sturdy and reliable connection for your projects. What are the Benefits of Brazing Steel to Steel? Strong Bond: Brazing creates a strong bond between the base metals without melting them. Learn how to braze steel like a pro with this comprehensive guide that covers everything from fluxing and flame adjustment to proper post-braze cleaning.Brazing is the process of joining two independent pieces of metal to form one strong load-bearing joint. Brazing is similar to soldering, but at higher temperatures. Use the right brazing rod material for the metal used in your project. Brazing is a joining process where melting a filler metal into the joint creates permanent solid bonds. Brazing requires a small joint spacing to allow capillary action to draw the molten filler metal into the joint. Both welding and brazing utilize heat to join materials, but the essential difference is the temperature.

metal brazing pros and cons

Brazing steel with a propane torch involves cleaning joint surfaces, applying flux, heating the joint with the torch until red-hot, and feeding a brazing filler rod into the joint. The filler melts and flows into the joint, forming a strong bond when cooled. Brazing is a high-temperature joining process where a filler metal is heated to a temperature typically exceeding 450°C (842°F). This temperature is carefully selected to be above the liquidus point of the filler metal but below the solidus . To braze weld sheet metal, first, clean the metal surfaces, apply flux, heat the metal, and then apply the brazing rod. Braze welding can be done with a torch, furnace, or induction heater. It provides strong, durable joints that are resistant to corrosion and wear. Learn how to easily braze steel, iron, brass, bronze, or copper using the supplies shown in this video that yield excellent results! You'll be able to make m.

Learn how to braze metal using a blow torch and brazing rod with these step by step instructions. This project features clear, animated illustrations and diagrams showing you every step you need to make a solid join with a blow torch or brazing rod.

Use these easy steps and procedures on how to braze metal to create solid joints like a pro: Scrub the metal surface using a wire brush or emery cloth. Then use soapy water or a degreaser to clean the metal surfaces. Place the metal in an appropriate position for .

45a junction box cooker

how to braze metal together

What is the best welding type for sheet metal? You can use both TIG and MIG welding for sheet metal welding. Yet, TIG welding is better for thinner pieces of metal.

brazing steel sheet metal|metal brazing pros and cons