cnc machine iron Cast Iron is a popular material for mass production components. It is attractive to machine, primarily due to the very small chips it creates at almost any cutting condition. Machinability is . Electrical boxes are an essential part of any home electrical system. There are several types of electrical boxes, and they all house wiring connections, the parts of your electrical system where wires join an outlet, switch, or even other wires.

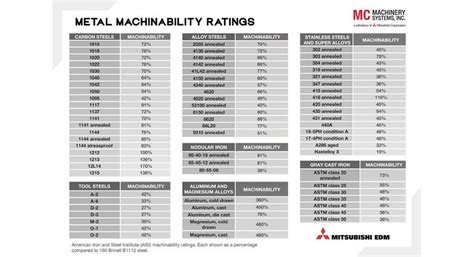

0 · cast iron machinability chart

1 · cast iron machinability

2 · cast iron in cnc

3 · cast iron cnc machine

Precision machining is specified by OEMs (original equipment manufacturers) to transform materials. A precision machinist is someone who takes a raw piece of material — often metal — and shaves it down to a .

Cast iron CNC machining is a subtractive manufacturing method that enables extremely precise production of complex parts from solid blocks of cast iron. The process begins with a Computer Numerical Control (CNC) machine, which .Cast iron can be CNC machined into finished components 2X as fast with less tool wear than most steel varieties. It is a dependable wear-resistant material and is an ideal material for .Cast Iron is a popular material for mass production components. It is attractive to machine, primarily due to the very small chips it creates at almost any cutting condition. Machinability is .

Cast iron is a versatile metal used in various automotive components such as engine blocks, heads, flywheels, and brake rotors, as well as everyday items like household pots and road manhole covers. However, there are several types of .Cast iron CNC machining is a subtractive manufacturing method that enables extremely precise production of complex parts from solid blocks of cast iron. The process begins with a Computer Numerical Control (CNC) machine, which can be programmed to accurately cut components out of the block of material in accordance with a specification.Cast iron can be CNC machined into finished components 2X as fast with less tool wear than most steel varieties. It is a dependable wear-resistant material and is an ideal material for absorbing vibrations. Cast iron can be heat treated without distortion or carburization.Cast Iron is a popular material for mass production components. It is attractive to machine, primarily due to the very small chips it creates at almost any cutting condition. Machinability is relatively high and depends mainly on production quality and hardness.

This article will introduce you to CNC machining cast iron from the definition, types, advantages, surface finishes, applications of cast iron parts and tips.Our Cost-effective Cast Iron CNC Machining Service offers the best value, balancing high-quality outputs with competitive pricing. Furthermore, the Fast Cast Iron CNC Machining Service significantly shortens production times, making it a reliable choice for clients under tight deadlines. Nodular cast iron is applicable for hubs and structural parts like machine frames in wind power industry and is good for complex and large shapes and high loads. Ductile cast iron has great vibration dampening, so it is better than steel when it .Get any number or type of iron, ductile iron, or cast iron parts made using a variety of factory processes, including CNC machining, milling cast iron, CNC turning, and more.

High-speed machining techniques and wear-resistant coatings for cutting tools are essential for cost savings in cast iron machining. These strategies minimize tool wear, enhance machining efficiency, and reduce the frequency of tool replacements, ultimately lowering costs.Cast iron is ideal for CNC machining methods that require low speed and high torque, such as boring, threading, and tapping. It holds heat for a long time, and distributes it evenly. It also adds a rich and smoky flavor to the part.

Cast iron is a versatile metal used in various automotive components such as engine blocks, heads, flywheels, and brake rotors, as well as everyday items like household pots and road manhole covers. However, there are several types of .Cast iron CNC machining is a subtractive manufacturing method that enables extremely precise production of complex parts from solid blocks of cast iron. The process begins with a Computer Numerical Control (CNC) machine, which can be programmed to accurately cut components out of the block of material in accordance with a specification.Cast iron can be CNC machined into finished components 2X as fast with less tool wear than most steel varieties. It is a dependable wear-resistant material and is an ideal material for absorbing vibrations. Cast iron can be heat treated without distortion or carburization.

Cast Iron is a popular material for mass production components. It is attractive to machine, primarily due to the very small chips it creates at almost any cutting condition. Machinability is relatively high and depends mainly on production quality and hardness. This article will introduce you to CNC machining cast iron from the definition, types, advantages, surface finishes, applications of cast iron parts and tips.Our Cost-effective Cast Iron CNC Machining Service offers the best value, balancing high-quality outputs with competitive pricing. Furthermore, the Fast Cast Iron CNC Machining Service significantly shortens production times, making it a reliable choice for clients under tight deadlines.

Nodular cast iron is applicable for hubs and structural parts like machine frames in wind power industry and is good for complex and large shapes and high loads. Ductile cast iron has great vibration dampening, so it is better than steel when it .

Get any number or type of iron, ductile iron, or cast iron parts made using a variety of factory processes, including CNC machining, milling cast iron, CNC turning, and more.High-speed machining techniques and wear-resistant coatings for cutting tools are essential for cost savings in cast iron machining. These strategies minimize tool wear, enhance machining efficiency, and reduce the frequency of tool replacements, ultimately lowering costs.

neptune electrical box

cast iron machinability chart

cast iron machinability

What is a Two Box metal detector? A Two Box metal detector is used for locating real deep targets, such as buried pipes, treasure caches etc. Not designed for finding single coins and small objects, target must be at least a size of a soda can.

cnc machine iron|cast iron cnc machine