flange weld sheet metal Sheet metal flanges and pipes and good examples of flare grooves. What Is a Flare Bevel Groove Weld? A flare bevel groove weld is where one component has a radius and the other has a flat face, such as below: This box is where the various lights, Tail, Brake, Clearance, are connected to the cord connecting your trailer to the tow vehicle. Also includes brake wire and backup lights (if .

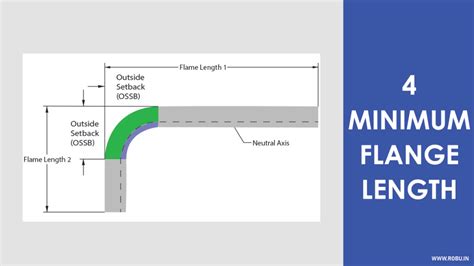

0 · sheet metal minimum flange length

1 · sheet metal guidelines pdf

2 · sheet metal enclosure design guide

3 · minimum bending radius sheet metal

4 · hole to distance sheet metal

5 · flange length in sheet metal

6 · flange calculation sheet

7 · extruded hole in sheet metal

A junction box, also known as an electrical junction box or junction can, is an enclosure that connects and splits electrical wires and cables. Junction boxes permit access to wiring for maintenance, inspection, and installation.

sheet metal minimum flange length

Compatible with all sheet metal materials, spot-welded flanges can be welded insideor outside a part to create a joint between two pieces. .

Sheet metal flanges and pipes and good examples of flare grooves. What Is a Flare Bevel Groove Weld? A flare bevel groove weld is where one component has a radius and the other has a flat face, such as below: Corner Joint Welding Definition. Corner Joint Welding is a process of joining two parts at a 90-Degree angle (right angle), making an L-Shape joint. This type of welding is .A sheet metal flange can be a projection, a rim, or both. It adds strength, attaches a part, or creates a flat surface. The edges of sheet metal are usually bent or welded to create flanges. These flanges are used in many different .

wiring a electrical panel box

sheet metal guidelines pdf

The sheet metal fabrication shop has several options when making a rectangular flanged connection. One is to use have the flange an integral piece make from the duct, or to add a proprietary flange (#1) on to the .

Welding flange from a material point of view is divided into mild steel and stainless steel. Stainless steel welded flanges are used for liquid and gaseous media with the use of resistance welding or friction welding technique. An edge-to-edge joint is a type of welding joint where the two pieces of metal being joined are placed flush with each other, creating a weld-like surfacing weld. This type of joint is often used when joining sheet metal or thin .The Welded Corner PropertyManager allows you to add a weld bead to the corners of a folded sheet metal part, including miter flanges, edge flanges, and closed corners. To open this . To weld thin stock successfully, use a small diameter tungsten electrode like 0.020, 0.040, and 1/16 in. Large-diameter tungsten electrodes require higher amperage to start the arc, leading to warping or burning of the .

I was not paying attention to the thickness of sheet you were specifying .9 of a mm is equivalent to 20gauge sheet metal. In normal industrial practice it is more common to put a spot welded tab flange with a sealant, rather than a weld. If you insist on torch welding this part (TIG) heliarc is recommended.

102mm Throttle Body Intake Weld Flange . ICT Billet 102mm Throttle Body Weld Flange Sheet Metal Intake Manifold .102mm Throttle Body Intake Weld Flange.For custom fabricated intake manifolds.Compatible with: 102mm 4-bolt LS style throttle body.Includes: 1 weld flange (1/2" thick) with 1 O-ring seal.Made in the USA from Aerospace grade billet . Gas welding sheet metal is a great way to join two pieces together quickly and efficiently without having to rely on traditional methods such as soldering or brazing. With the right tools and know-how, however, anyone can . Flanged Corner Weld joint. Flange corner joint is a type of edge weld. It is a form of a corner joint where the butting part has a flanged edge shape at the weld joint. . They are used in machine parts, box members, sheet metal welding and structural applications. See also Effects of alloying elements on the weldability of metals (with PDF .

once again, I am having hard time with sheet metal - edge flange feature. I need to have these flanges on all these three edges (marked in red) but there is problem with two bottom ones. They intersect each other in flatten state. My idea was to edit each flange and make a 45° cut. Sheet metal flanges and pipes and good examples of flare grooves. . A flare bevel groove weld is often used in sheet metal for connecting flanges: What Is a Flare V Groove Weld? A flare bevel groove weld is where the radius is .Defines a flange by adding a sheet metal face, a bend, and other parameters to an edge or edge loop on a face. What's New: 2021, 2025. The Flange Property Panel populates with the default settings from the active Sheet Metal Style. You can override these settings on a per flange basis or on a set of flanges.

wiring a junction box nz

Overlapping Flange for Seam Weld in Sheet Metal I'm trying to create an overlapping flange from two adjacet previosly created flanges. The purpose is to create a closed corner to a box and provide for a lap weld rather than edge weld. I can't seem to creat an offset such that the new flange doesn't merge with the adjacet flange.

The Welded Corner PropertyManager allows you to add a weld bead to the corners of a folded sheet metal part, including miter flanges, edge flanges, and closed corners. To open this PropertyManager: Click Welded Corner (Sheet Metal toolbar) or Insert > Sheet Metal > Welded Corner , and select one of the corner faces.

A lap or flange weld will lead to corrosion later down. Even with weld thru primers you still burn that corrosion protection away at the weld site. That burnt paint makes for a hot spot for rust. . and ive always been told that a butt weld is the strongest weld for sheet metal, but, i just did a patch job on a friends 1/4 panel and there .

The Eastwood Pneumatic Perfect Panel Prep Tool easily provides a perfectly beveled 45° weld-prepped edge in 20 or 18 Gauge sheet metal to achieve solid, full-penetration welds with little distortion. Each pull of the trigger will create an .062″ flange with a 45 degree flange that will give you flush lap joint when laying 20 or 18 gauge over . Welding of sheet metal; Reinforcing plate welding in flanges; Joining two angles, square pipes on structures. Welding of mufflers. Edge to Edge Joint. An edge-to-edge joint is a type of welding joint where the two pieces of metal being joined are placed flush with each other, creating a weld-like surfacing weld. This type of joint is often used .Having sheet metal surfaces touch each other tends to throw things out of wack. If you have a joint that is supposed to be riveted or welded, leaving some small offset (even .0001in) between the surfaces helps keep the CAD from complaining. As my Subject title says. I am trying to change the flange gap size to .01" so the weld seam can be fused with no filler metal. I have done it before but the menu is greyed out and I am not sure how I have done it in the past. See attached for menu screenshot.

The flange approach for some reason seems less daunting but butt weld is fusing metal at the molecular level so just like what was there originally. takes a little more patience to spot weld it. My 69's quarters I wanted to put skins on at the top body line. came out almost perfect without body filler. Sheet Metal Flange Forming: Sheet metal forming refers to a broad set of manufacturing processes used to convert flat metal sheets into desired shapes and geometries. It is an essential part of the metalworking industry, widely used in the automotive, aerospace, construction, and electronics industries. . In a U-groove weld, the edges of the .

You can add closed corners between sheet metal flanges. Flattening Sheet Metal Bends. No Bends. You can roll back all bends from a sheet metal part in which bends have been inserted so that you can make additions, such as adding a wall. This is available only in sheet metal parts with Flatten-Bends1 and Process-Bends1 features. Jogs Get the 2 pieces as close together as possible with clamps, vice grips, sheet metal screws or even dent it if you have to. Cut the mig wire flush with the nozzle every time before you start, I like to start the weld on the frame rail in the centre .Setter, 5mm Hole Punch Plier Setting Hand Joggler Panel Flanging Plier Sheet Metal Repair Welding Puncher Flange Tool 4.2 out of 5 stars 6 2 offers from 39 $ 36 39

Edge weld symbols are most commonly associated with sheet metal or “gauge” material. This gauge is a system used in order to call out sheet metal similar to that of electricians and wire. This chart can range from the largest gauge of carbon steel at #7 which is a decimal of .1793” all the way to the smallest which is #28 at a decimal of .Price Sheets. Get current price sheets on our extensive product inventory via the links below. NOTE: The below buttons link to Microsoft xlsx files. On clicking the button it may open in a new window or may save to your downloads folder. I had taken sheet metal forming & welding at a vocational school many moons ago. I had checked out pricing on a refresher course but it is out of my price range at the moment. . So that flange is made with a flange tool that bends the metal to have a Z bend in it, that the replacement piece lies on the Z part and, where the seam is, should be . For spot welding sheet metal, you will need access to an electric arc welder, which comes in various sizes depending on your specific needs. . Read More Expander Flange Price List. Forged Flange Price List. Read More Forged Flange Price List. CATEGORIES. B2b Blogs (2) Dimensions (7) Fasteners (887) flanges (163) Flanges (69) Formulas (5)

In this video Pete will demonstrate a technique for creating an elliptical sheet metal flange, when the Contour Flange tool is unable to do so. This will al. Weld-through primer is not used, as the bare metal on the flanges is completely coated with the adhesive. Weld bonding typically requires higher squeeze pressure at the welding machine tips than STRSW alone. Welding sheet metal has always been an important part of collision repairs.

Turned one way, the tool produces a neat flanged edge in sheet metal, just the right depth for welding two pieces together. Turn the head 180 degrees and the tool becomes a hole punch, producing 3/16"-diameter holes perfect for easy riveting or plug welding. Flanger; Hole Punch; For metal up to 18-gauge; 8"-long handle produces greater leverage

This is an education channel for all Engineers who enthusiast with 3D CAD, CAE, and CAM. Thank you for your kindly appreciation and please Subscribe.

sheet metal enclosure design guide

What is CNC technology? Learn about its history, principles, major machine types, applications, advantages, and limitations with X Rapid Technologies.

flange weld sheet metal|minimum bending radius sheet metal