cad drawing cnc machine Speed up 2D, 2.5D, 3-, 4-, and 5-axis CAM programming with automation and user-defined templates built around your best practices. Make better use of your 4- and 5-axis CNC machines. Produce high-quality parts using fewer setups . The typical switch loop wiring is to connect the switch cable white wire to all the black hot wires in the box. Then the switch cable black wire is connected to the fixture black wire. Finally, the fixture white wire is connected to all the white .

0 · programs for cnc router machine

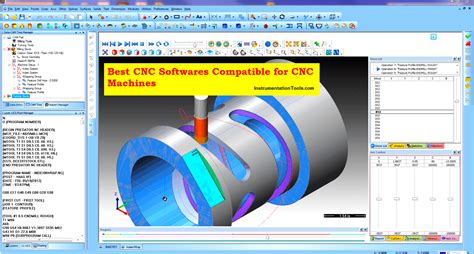

1 · programming software for cnc machines

2 · how to make cnc files

3 · cad software for cnc machine

4 · cad drawing for cnc machine

5 · autocad for cnc machine

6 · auto cad cnc drawing

7 · 3d cnc programming software

$59.99

Computer-Aided Design (CAD) software for CNC (Computer Numerical Control) machines is a type of program that helps engineers and designers create precise 3D models of parts and . This article guides you through every step you should follow to properly prepare your CAD files for the next step, presumably CNC machining. Keep reading below to .

Modern CNC machining systems can interpret the part geometry directly from the 3D CAD file with the onboard computer or receive the G-code output of the CAM software.Speed up 2D, 2.5D, 3-, 4-, and 5-axis CAM programming with automation and user-defined templates built around your best practices. Make better use of your 4- and 5-axis CNC machines. Produce high-quality parts using fewer setups .Connect disciplines using common CAD models to program CNC machines. Design fixtures and create toolpaths before engineering data is released—any changes automatically update computer-aided manufacturing (CAM) workflows. CNC machining drawings are essential for precision manufacturing, bridging the gap between design and product. They guide the machining process with detailed specifications, utilizing CAD software for .

In this article, we’ll explain when to include a technical drawing (or machining blueprints) in your CNC order and what you need to include to get the most out of part sourcing. This article also includes technical drawing guidelines and best .

Upload your CAD file and 2D technical drawing for a quick, accurate quote tailored to your project’s specifications. Our AI-powered technology helps streamline CNC machining, ensuring you can quickly move from design to .

In this guide, I will walk you through the process of creating technical drawings for CNC machining projects, from start to finish. I will cover everything from the basics of drawing software to more advanced techniques . This article will help you learn how to prepare CAD files for CNC machining. It discusses CAD design considerations for CNC machining and industry best practices.Computer-Aided Design (CAD) software for CNC (Computer Numerical Control) machines is a type of program that helps engineers and designers create precise 3D models of parts and assemblies to be produced on a CNC machine.

This article guides you through every step you should follow to properly prepare your CAD files for the next step, presumably CNC machining. Keep reading below to understand more about the process through our step-by-step guide. Modern CNC machining systems can interpret the part geometry directly from the 3D CAD file with the onboard computer or receive the G-code output of the CAM software.

Speed up 2D, 2.5D, 3-, 4-, and 5-axis CAM programming with automation and user-defined templates built around your best practices. Make better use of your 4- and 5-axis CNC machines. Produce high-quality parts using fewer setups which lowers production costs. Dedicated 2D turning strategies.

Connect disciplines using common CAD models to program CNC machines. Design fixtures and create toolpaths before engineering data is released—any changes automatically update computer-aided manufacturing (CAM) workflows. CNC machining drawings are essential for precision manufacturing, bridging the gap between design and product. They guide the machining process with detailed specifications, utilizing CAD software for efficiency and accuracy, thus .

In this article, we’ll explain when to include a technical drawing (or machining blueprints) in your CNC order and what you need to include to get the most out of part sourcing. This article also includes technical drawing guidelines and best practices from our engineers.Upload your CAD file and 2D technical drawing for a quick, accurate quote tailored to your project’s specifications. Our AI-powered technology helps streamline CNC machining, ensuring you can quickly move from design to production.

In this guide, I will walk you through the process of creating technical drawings for CNC machining projects, from start to finish. I will cover everything from the basics of drawing software to more advanced techniques such as 3D rendering. This article will help you learn how to prepare CAD files for CNC machining. It discusses CAD design considerations for CNC machining and industry best practices.

programs for cnc router machine

Computer-Aided Design (CAD) software for CNC (Computer Numerical Control) machines is a type of program that helps engineers and designers create precise 3D models of parts and assemblies to be produced on a CNC machine. This article guides you through every step you should follow to properly prepare your CAD files for the next step, presumably CNC machining. Keep reading below to understand more about the process through our step-by-step guide. Modern CNC machining systems can interpret the part geometry directly from the 3D CAD file with the onboard computer or receive the G-code output of the CAM software.Speed up 2D, 2.5D, 3-, 4-, and 5-axis CAM programming with automation and user-defined templates built around your best practices. Make better use of your 4- and 5-axis CNC machines. Produce high-quality parts using fewer setups which lowers production costs. Dedicated 2D turning strategies.

Connect disciplines using common CAD models to program CNC machines. Design fixtures and create toolpaths before engineering data is released—any changes automatically update computer-aided manufacturing (CAM) workflows. CNC machining drawings are essential for precision manufacturing, bridging the gap between design and product. They guide the machining process with detailed specifications, utilizing CAD software for efficiency and accuracy, thus .In this article, we’ll explain when to include a technical drawing (or machining blueprints) in your CNC order and what you need to include to get the most out of part sourcing. This article also includes technical drawing guidelines and best practices from our engineers.Upload your CAD file and 2D technical drawing for a quick, accurate quote tailored to your project’s specifications. Our AI-powered technology helps streamline CNC machining, ensuring you can quickly move from design to production.

china cnc copper nut manufacturers

china car interiors cnc cutting machine

$176.60

cad drawing cnc machine|cad drawing for cnc machine