cnc 5-axis machine types Here's how 5-axis CNC machines are transforming manufacturing: 1. What is 5-Axis CNC Machining? Unlike traditional 3-axis systems, 5-axis machines move a part or tool along . Yes, underwater potting compound can be used for other projects. Use in projects where you may find yourself using waterproof potting . See more

0 · small 5 axis cnc milling machine

1 · haas 5 axis cnc machine for sale

2 · benefits of 5 axis machining

3 · 5 axis machining explained

4 · 5 axis cnc milling machine for sale

5 · 5 axis cnc machine specifications

6 · 5 axis cnc machine diagram

7 · 5 axis cnc explained

Find company research, competitor information, contact details & financial data for UNI-Max Food Distribution Corp of Randolph, MA. Get the latest business insights from Dun & Bradstreet.

What are the types of 5-axis CNC machines? To meet the different needs of the market, CNC equipment manufacturers provided different types of 5-axis CNC machines. .

There are three primary types of 5 axis CNC machines, each with its unique configuration and capabilities: Head/Head: In this type, the spindle head (the top part that holds the cutting tool) and the rotary axis are on the . Here's how 5-axis CNC machines are transforming manufacturing: 1. What is 5-Axis CNC Machining? Unlike traditional 3-axis systems, 5-axis machines move a part or tool along . What are the Different Types of 5-Axis CNC Machines? 5-axis CNC machines come in various types, each with distinct configurations and capabilities. Understanding these types is crucial for manufacturers to harness . The main distinction between the different types of 5-axis CNC machines is the rotational axis location (machine spindle head or the table). Below are the three common types of 5-axis CNC systems so you can choose .

The three major types of 5-axis CNC machines are: Head/Head. Head/Head machines have rotational axes located in the head. Their 5-axis apex comes on a platform that moves through a fixed worktable, keeping the . At its core, 5-axis machining refers to the capability of a CNC machine to move a part or a tool on five different axes simultaneously. Traditional 3-axis machines operate on the X, Y, and Z axes, allowing movement in three .

If you’re in the market for a new CNC machine, whether it’s a lathe, router, mill, or other type, we have a comprehensive explanation of 5-axis CNC machines and their benefits so you make the best choice. What are the types of 5-axis CNC machines? To meet the different needs of the market, CNC equipment manufacturers provided different types of 5-axis CNC machines. Among the types, there is a basic difference in the flexibility of table rotation or cutting tool movement in different directions.

There are three primary types of 5 axis CNC machines, each with its unique configuration and capabilities: Head/Head: In this type, the spindle head (the top part that holds the cutting tool) and the rotary axis are on the machine’s head.

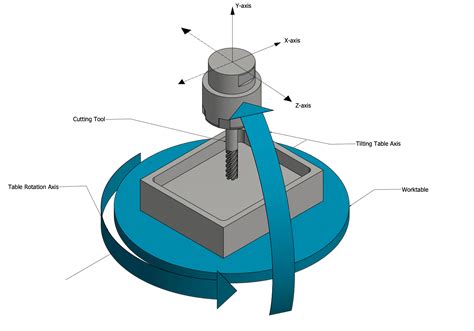

Here's how 5-axis CNC machines are transforming manufacturing: 1. What is 5-Axis CNC Machining? Unlike traditional 3-axis systems, 5-axis machines move a part or tool along three linear axes (X, Y, Z) while rotating it along two additional axes (A, B). This capability allows manufacturers to approach the workpiece from virtually any angle . What are the Different Types of 5-Axis CNC Machines? 5-axis CNC machines come in various types, each with distinct configurations and capabilities. Understanding these types is crucial for manufacturers to harness the full potential of . The main distinction between the different types of 5-axis CNC machines is the rotational axis location (machine spindle head or the table). Below are the three common types of 5-axis CNC systems so you can choose the right one for your project.

The three major types of 5-axis CNC machines are: Head/Head. Head/Head machines have rotational axes located in the head. Their 5-axis apex comes on a platform that moves through a fixed worktable, keeping the workpiece in place. Therefore, you won’t need to worry about tool interference on the machine spindle head. At its core, 5-axis machining refers to the capability of a CNC machine to move a part or a tool on five different axes simultaneously. Traditional 3-axis machines operate on the X, Y, and Z axes, allowing movement in three primary directions: up and down, left and right, and forward and backward. Perhaps the most common type of 5 axis machining system are CNC mills. They are ideal for machining hard materials, primarily metal. CNC mills work by rotating the part along two axes while moving it along three linear axis. Similar to mills, CNC routers have a rotating spindle that can move along two rotational axes with three linear axes.As the name implies, 5-axis CNC machining covers five machining axes, three linear and two rotational. The linear axes are the X-axis (left to right movement), Y-axis (forward and backward movement), and Z-axis (up and down movement).

If you’re in the market for a new CNC machine, whether it’s a lathe, router, mill, or other type, we have a comprehensive explanation of 5-axis CNC machines and their benefits so you make the best choice. What are the types of 5-axis CNC machines? To meet the different needs of the market, CNC equipment manufacturers provided different types of 5-axis CNC machines. Among the types, there is a basic difference in the flexibility of table rotation or cutting tool movement in different directions. There are three primary types of 5 axis CNC machines, each with its unique configuration and capabilities: Head/Head: In this type, the spindle head (the top part that holds the cutting tool) and the rotary axis are on the machine’s head. Here's how 5-axis CNC machines are transforming manufacturing: 1. What is 5-Axis CNC Machining? Unlike traditional 3-axis systems, 5-axis machines move a part or tool along three linear axes (X, Y, Z) while rotating it along two additional axes (A, B). This capability allows manufacturers to approach the workpiece from virtually any angle .

What are the Different Types of 5-Axis CNC Machines? 5-axis CNC machines come in various types, each with distinct configurations and capabilities. Understanding these types is crucial for manufacturers to harness the full potential of . The main distinction between the different types of 5-axis CNC machines is the rotational axis location (machine spindle head or the table). Below are the three common types of 5-axis CNC systems so you can choose the right one for your project.

The three major types of 5-axis CNC machines are: Head/Head. Head/Head machines have rotational axes located in the head. Their 5-axis apex comes on a platform that moves through a fixed worktable, keeping the workpiece in place. Therefore, you won’t need to worry about tool interference on the machine spindle head. At its core, 5-axis machining refers to the capability of a CNC machine to move a part or a tool on five different axes simultaneously. Traditional 3-axis machines operate on the X, Y, and Z axes, allowing movement in three primary directions: up and down, left and right, and forward and backward. Perhaps the most common type of 5 axis machining system are CNC mills. They are ideal for machining hard materials, primarily metal. CNC mills work by rotating the part along two axes while moving it along three linear axis. Similar to mills, CNC routers have a rotating spindle that can move along two rotational axes with three linear axes.

small 5 axis cnc milling machine

precision machining titanium parts

Tamper-resistant junction box for UniFi Bullet, Dome, and Turret cameras that enhances mounting durability, aesthetics, and ease of maintenance. Supports flat surface, pole and pendant mounting Includes side and rear 3/4" conduit .

cnc 5-axis machine types|small 5 axis cnc milling machine