sheet metal bending bars $125.00 $283.99

0 · solid steel round bar bender

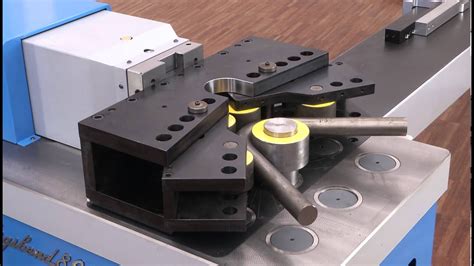

1 · sheet metal bending allowance chart

2 · machine for bending steel bar

3 · best steel rod for bending

4 · bending stainless steel flat bar

5 · bending metal rods by hand

6 · bending flat bar 90 degrees

7 · basics of bar bending schedule

Mounting brackets are your best choice for walls and shelves. If you’re looking for a strong L bracket, metal options are ideal. They come in a variety of standard sizes and are constructed of either steel or wrought iron. For corner joints, a heavy-duty corner brace or corner bracket can provide additional strength and support.

12 Inch Sheet Metal Folding Tool - Ultimate HVAC Sheet Metal Bender, Hand Seamer, Metal Forming Tool for Duct Work & Metal Roofing; Premier Sheet Metal Folding Bar & Bending Tool .12 Inch Sheet Metal Folding Tool - Ultimate HVAC Sheet Metal Bender, Hand .The Eastwood 48" Electro-Brake Sheet Metal Brake Consistent Repeatable .

stainless steel lunch box microwave safe

.99Choose from our selection of sheet metal benders, including over 50 products in a wide range of styles and sizes. In stock and ready to ship.As a full-service fabrication company, one of our many specialties include custom metal bending for pipes, bars, beams and tubes. We can take your custom prototype or designs and bring it to life for your specific project and needs. . Alloy Steel Aluminum Brass Carbon Alloys Copper Sheet Metal Stainless Steel. Max Weiss. 8625 W Bradley Rd .This folding tool makes it very simple to bend sheet metal. It's 24 in. L x 3 1/4 in. W and made of heavy 16- gauge steel. On one side of the folding tool it bends 3/8 in. And the other side it bends 1 in. On the folding tool there is 8 alignment .

Shape sheet metal using your bench vise as a sturdy base. Remove or slide the four dies along the clamping bar to form angles, channels, boxes, trays, and pans in a variety of widths. Unlike bench-top and floor-mount benders, these are not permanently mounted— pull them out when you need them and store them when you don’t.Sheet Metal Brake: A sheet metal brake is a hand-operated tool that clamps the sheet metal between a bending plate and a clamping bar, allowing the user to apply force and create the desired bend. Seaming Pliers: These pliers have broad, flat jaws designed to grip and bend sheet metal along a straight edge, making them ideal for creating seams .

**Versatile Metal Bending Tool** This sheet metal bending tool allows you to tackle a variety of projects including roofing and custom ductwork; any task requiring reliable sheet metal forming tools. **Professional-Grade** Featuring an efficient folding for sheet metal, this tool delivers clean, accurate bends every time.

Klein Tools 86532 Metal Folding Tool for Duct Bending 18 x 3-Inch Folds Up to 24 ga CRSM and 28 ga Stainless - Amazon.com. . SDSNTE 24 In 16 Ga Steel Sheet Metal Folding Tool with Grips for Creating Uniform Folds Fits HVAC Applications and Pipefitter, Red, Pack of 1.If you’re utilizing 3D CAD software, d raw the part with the flanges in place using the sheet metal function in whatever CAD software you are using. Once you have the flanges in place, edit the bend radius to match the advanced details found at the bottom of the bending calculator. . The K-factor in sheet metal bending represents the ratio .VEVOR Box and Pan Brake, 48-Inch, 0-130 Degrees Sheet Metal Bending Brake, Portable Mini Metal Bender with 20 Gauge Low Carbon Steel 14 Gauge Aluminum Capacity Power Handle, for Metal Bending. 5.85 $ 165. 85. . Single Phase 220V with Foot Pedal Controller | Includes 9 Pcs Clamp Bars. ,599.99 $ 3,599. 99.

Precision Sheet Metal Bending: Our core expertise lies in the art of precision sheet metal bending. We have state-of-the-art equipment and a highly skilled team of technicians who excel in bending sheet metal with exceptional accuracy. Whether you need simple bends or complex geometries, we have the capabilities to deliver unmatched results.Mini Flat Bar Rod Bender, Rebar Metal Bending Hand Tools for DIY Iron Creative Hangings, Maximum Bendable Diameter 10mm (3/8") 2.4 out of 5 stars. 3. . Folding Tool Steel Metal Bending Tool Sheet Metal Bender for HVAC Metal Bending Forming 3/8 and 1 Fold Depths in Ductwork (12 Inch) 4.7 out of 5 stars. 41. The folding of sheet metal is carried out using a cornice brake or a bar folder, and it comprises a clamping beam that helps to bend the metal sheet and achieve the desired shape. The metal sheet is bent in a V-shape with a positive or a negative angle.

The greater the radius, the less is friction between the die and the sheet metal during bending. Common punch tip radius includes: . ⑧ It is not recommended to use press brake dies for bending hard or excessively thick materials .Save space in your shop by cutting, bending, and curving sheet metal with a single machine. Also known as shear brake rolls. Use the blade on the shear to make clean, straight cuts; it has two cutting edges for twice the life. A press brake makes bends up to 90°. Create curves and circles with the slip roll.. When using the shear or press brake, set the manual back gauge to . Your part is in the sheet metal environment, which is intended to work with uniform thickness materials (sheet metal, for instance). The Bend tool is in the normal modeling environment, and if you change over to that environment, you will be able to bend your bar using the sketch you created.

Klein Tools 86532 Metal Folding Tool for Duct Bending 18 x 3-Inch Folds Up to 24 ga CRSM and 28 ga Stainless . in Rebar Cutters & Benders . 6 offers from 99 $ 20 99. SDSNTE 24 In 16 Ga Steel Sheet Metal Folding Tool with .

Bend Radius - As a rule, inside bend radius should be equal to material thickness. When the radius is less than recommended, this can cause material flow problems in soft material and fracturing in hard material. Bend Relief - When a bend is made close to an edge the material may tear unless bend relief is given. Figure "A" shows a torn part. The Eastwood 48" Electro-Brake Sheet Metal Brake. Consistent Repeatable Accurate Bends . Bends up to 16 ga mild steel and 20 ga stainless; Six tons of consistent clamping force across entire bending surface; Complete .

Malco’s 12F, 18F, and 24F Sheet Metal Folding Tools offer a premium choice for bending and forming metal. Each model is made with superior design and includes handy sight holes to ensure proper depth alignment. Whether you are an HVAC or roofing pro, Malco offers you the right tool to get the job done.Master the art of bending sheet metal with Shengen, a B2B sheet metal parts manufacturer. Learn basics, advanced techniques, and safety tips. . The flat surface holds the metal, and the clamping bar secures the sheet metal down during the bending process. How to Leverage a Mallet and Vise.Mini Metal Sheet Brake: Max. Bending width: 36 inches/910 mm; Max. Bending thickness: 0.04 inches/1 mm. Our metal sheet brake is a great tool to bend your metal sheets, with its extraordinary bending performance making itself quite a .BAR BENDING MACHINE - Free download as PDF File (.pdf), Text File (.txt) or read online for free. The document provides guidelines for safely operating a bar bending machine. It lists 10 pre-operational guidelines including ensuring guards are not removed, the machine is on a level foundation, it is properly earthed, moving parts are lubricated, and the work area is clear of .

This doesn’t just work with thin sheet metal. You can use this method to bend material that would make a sheet metal bending brake cry. So what is this 2-step diy bending process that can do the job of a press brake? Here’s the secret: Step 1 – Make relief cuts in your part along the line you want to bend. Step 2 – Bend. That’s it, no .This is 1” x 4” flat bar rolled to 180 degrees, making a U-bend. Rolling flat bar is one of our specialties at Jorgenson Metal Rolling & Forming, we also do heavy duty plate rolling to make things like pipe collars, pipe supports, pipe saddles, .Hydraulic powered Bending Brakes Chicago Dreis & Krump adds hydraulic power and push button bending to its legendary sheet metal hand brake family because you can save time, effort and money with all the extra muscle. These machines are easy to operate.

Sheet Metal Bending Common Types Of Sheet Metal Bending Techniques. Some of the most common bending methods are: Folding. A bar folder or cornice brake allows you to perform folding operations on sheet metal parts. A clamping beam is pivotal in bending the part into a desired shape upon clamping.American-made sheet metal fabrication equipment including powered folders, slitters, brakes, shears, slip rolls, cleat and cheek benders, notchers, and rotary machines. Brands include Tennsmith, Roper Whitney, Pexto and Connecticut. . 52.5″ Bending Bar (1) 26″ Bending Bar (1) 12″ Bending Bar (1) 6″ Bending Bar (1) 4″ Bending Bar .Raising the Bar on Bar Bending. Bar bending makes sense on many levels. In the hands of the skilled professionals at Max Weiss Company, your materials are bent to concise specifications, to meet specific needs. We bend round, half-round, square, hexagonal and rectangular (flat) bars into rings and ring segments.

solid steel round bar bender

Buy Junction Box Plastic Project Box Weatherproof Electric Power Cord Box for Outdoor at business.walmart.com Facilities Maintenance, Repair & Operations - Walmart Business Supplies

sheet metal bending bars|best steel rod for bending