sheet metal bend deduction formula Bend deduction is a crucial concept in the field of sheet metal fabrication, particularly in the bending process. It is commonly referred to as the “back-off amount” and plays a significant role in determining the accurate dimensions of a bent part. See more It is versatile and used for production in CNC machining, aluminum extrusion, and sheet metal fabrication processes. 6061 is the most popular grade aluminum material for CNC machining. Aluminum 6063 is good to be extruded, and aluminum 5052 is excellent for sheet metal forming.Precision CNC machining 6061 aluminum parts manufactured by CNClathing.com, aluminum 6061 is one of the most common aluminum alloy, a compact and defect-free material . See more

0 · stainless steel bend deduction chart

1 · sheet metal flat length calculator

2 · sheet metal blank size calculator

3 · sheet metal bending calculator free

4 · sheet metal bend length calculation

5 · sheet metal bend deduction chart

6 · sheet metal bend calculation formula

7 · calculating bend allowance sheet metal

$19.98

Bend deduction is a crucial concept in the field of sheet metal fabrication, particularly in the bending process. It is commonly referred to as the “back-off amount” and plays a significant role in determining the accurate dimensions of a bent part. See moreBend deduction (BD) is a critical factor in sheet metal fabrication, used to calculate the flat pattern length of a sheet metal part. It accounts for the material that is displaced during the . See more

The dimensional accuracy of bent workpieces is related to the positional precision of the press brake’s back gauge and the precision of the sheet metal cutting machine. . See moreThe Bend Deduction Formula takes into account the geometries of bending and the properties of your metal to determine the Bend Deduction. You will need to know your Material Thickness . A bend deduction (BD) is the value subtracted from the flat blank for each bend in the part, and there may be more than one. Bend deductions differ depending on the part itself, different bend angles, and/or inside radii. Learn how to accurately calculate bend allowance with our easy-to-understand formula. Improve your sheet metal bending operations and achieve precise results every time.

Bend Deduction is actually the measurement of the length that you will have to deduct from the total length of the flanges of the final sheet metal component, in order to get the correct length of the flat pattern that you need .

This tool calculates bend allowance/deduction based on material thickness, bend angle, inside radius, and k-factor, as you will learn from the bend allowance equation. Just input your parameters and start working! Consider a sheet with a 20 mm thickness and a length of 300 mm as shown in Figure 1. We are going to review three bending scenarios with three different bending angles; 60, 90 and 120, and we will calculate K-Factor, Bend .

Here’s the formula: Bend deduction = (2 × Outside setback) - Bend allowance. With the bend deduction in hand, you can determine the appropriate flat blank size, and program the press brake so that the backgauge fingers .

The Bend Deduction Formula takes into account the geometries of bending and the properties of your metal to determine the Bend Deduction. Values you will need to know will include your material thickness (MT), the .

You just have to collect some required data like K-factor, sheet metal thickness, bend angle, and inside radius of the bend. If you have the values of these variables, you can simply put them in the formula and calculate the . Hello could someone please help with a formula? I'm trying to work out the bend deduction for sheet metal parts. I have the formula but I just don't know how to input it into excel. I've attached the formula here 819554 BA ? Bend allowance θ ? Bend angle in radians or degrees r ? Inside radius; T ? Material thickness. Here is my current try =2*(M3+M5)*TAN(M2/2)-L13

Step-1: Calculate the value bend allowance for the required sheet metal bend by using the below formula. Bend Allowance (BA) = (Π/180) × ( R + K×T) × A. Step-2: Calculate the value of bend deduction from the values of bend allowance . In precision sheet metal fabrication, choosing the correct die opening should not be a guessing game. . Bend allowance = [(0.017453 × Inside bend radius) + (0.0078 × Material thickness)] . Here’s the formula: Bend deduction = (2 × Outside setback) - Bend allowance. With the bend deduction in hand, you can determine the appropriate flat .

In order to develop the flat pattern, we will subtract .293” from 5” to arrive at 4.707”. The image below shows the close relation between Bend Deduction and Bend Allowance. BEND DEDUCTION FORMULA. The Bend Deduction Formula takes into account the geometries of bending and the properties of your metal to determine the Bend Deduction. Therefore, to achieve a 90° bend with a 3mm inside bend radius on this 2mm thick stainless steel sheet, we need to set the Bend Deduction to 5.61mm during the bending process. This means we need to over-bend the sheet by 5.61mm to compensate for the springback after bending, ultimately achieving the desired 90° bend angle.

Effortlessly calculate K factor, Y factor, bend allowance, bend deduction, and unfold length in your metal fabrication projects. Unlock higher accuracy and efficiency - try it now! . In sheet metal bending calculations, the impact of different material types on the bending factor is significant and multifaceted, influencing the accuracy .You can specify an explicit bend allowance or bend deduction for any sheet metal bend by entering the value when you create the bend. By definition, the bend allowance is the arc length of the bend as measured along the neutral axis of the material. By definition, the bend deduction is the difference between the bend allowance and twice the . Here the role of Sheet Metal bend Allowance comes into the picture. Bend Allowance and Bend Deduction both values can be used to calculate the size of the flat pattern. But in this article, I will just cover the first term. . Bend Allowance Formula. The bend allowance can be easily calculated by using the formula given below: Here, B = Bend .

The bending allowance coefficient for 2.0 sheet with hemming is 1.4. 6.0mm copper sheet bending allowance: 10.3; 8.0mm copper sheet bending allowance: 12.5; 10.0mm copper sheet bending allowance: 15; 12.0mm copper sheet bending allowance: 17; 3.0mm stainless steel with V25 allowance: 6; 3.0mm stainless steel with V20 allowance: 5.5

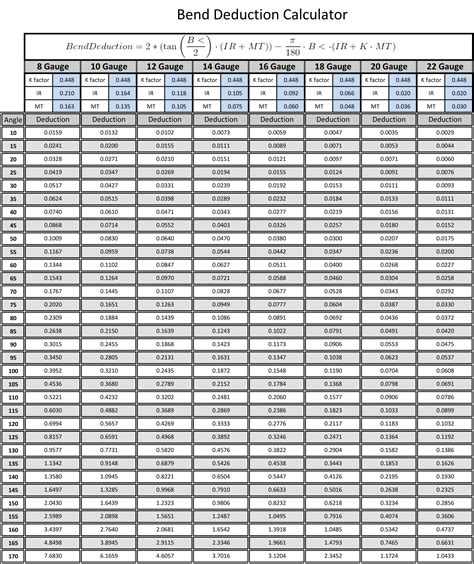

The Bend Allowance Formula takes into account the geometries of bending and the properties of your metal to determine the Bend Allowance. . Sheet Metal Bend Allowance Chart (PDF) Sheet Metal Bend Allowance Chart (Excel) BEND ALLOWANCE; 8 Gauge: 10 Gauge: 12 Gauge: 14 Gauge: 16 Gauge: 18 Gauge: 20 Gauge: 22 Gauge: 24 Gauge: K factor: At this point, the formula for bend allowance has incorporated the shifting of the neutral axis. Now calculate the values for outside setback (OSSB) and, finally, the bend deduction (BD)—that is, the total amount of elongation for a given bend. . Steve Benson is a member and former chair of the Precision Sheet Metal Technology Council of .

We generated the following bend allowance chart using the sheet metal bend allowance calculator for steel, assuming the K-factor of 0.45, bend angle of 90 degrees, and inside radius of 0.05 inches (1.3 mm). The actual K-factor may depend on the type of bending operation, the thickness of the sheet, and the material.The K-factor in sheet metal bending represents the ratio between the thickness of the metal and an invisible line called the “neutral axis.” When a flat piece of material is bent the inside face of the bend is compressed and the outside part stretches. . What is the bend deduction formula? The goal of the bend calculation is to predict .

The bend allowance and bend deduction are two measures that relate the bent length of a piece of sheet metal to the flat length. The bend allowance describes the length of the neutral axis between the bend lines, or in other words, the .Where an :ALLOWANCE_FORMULA is specified in a bend process table, Creo Elements/Direct Sheet Metal calculates the actual flat length by means of the applicable bend allowance formula or by a table interpolation method. The . Often bend allowances are calculated for a sheet metal part and used to make costly tooling or production parts that require a lot of labor to produce. A scrap tool or . Since is more common to develop a part based on degrees instead of radians, the bend allowance formula commonly incorporates the degrees to radians conversion.

Sheet metal right angle bend deduction calculator - formula & step by step calculation to find the difference between the sum of flange lengths and the initial flat length. BD = {[2(R + T) x tan(A/2)] - BA}. The inside bend radius R in m, material thickness T in m, bend angle A in degrees & bend allowance BA are the key elements of this . Press brake bend allowance refers to the additional material length required for a given bend angle in a metal sheet or plate when using a press brake. When . When the bending angle is 90°, the bending allowance formula can be simplified as .The following illustration shows the equation / calculation for determining the bend allowance when forming sheet metal. Most sheet metal materials will conform to the calculations. This page also includes a link to a on-line sheet metal bend allowance calculator. Open Sheet Metal Bend Allowance Calculator. Sheet Metal Bend Allowance Equations .

Hi I've have not had that much experience of working with sheet metal. I have been asked to draw a simple bracket (see attached). I have used 2mm thk aluminium. I have been asked to supply the overall length of the flat pattern (which is no problem), and the bend allowance. How do I get this???? I've looked online and found a formula: bend .When the sheet metal is bent the inside radius pulls the edge of the material away from the apex of the bend. Because this is a geometrical function it does not change with a metal’s K-Factor the way Bend Allowance and Bend Deduction do. The Inside Setback is closely related to, but should not be confused with, the Outside Setback. The below .This is what is known as the bend allowance. It is the material “consumed” in the bend. . Arc length of the neutral axis, 90° case only. A general formula for bend allowance that works in all cases converts the angle in degrees to radians . “Analyzing the K-Factor in Sheet Metal Bending: Part II.” The Fabricator – Metal . Use the sheet metal module or tools in the software: Most 3D CAD software provides related tools and functions for sheet metal design. For example, Creo offers a variety of methods for controlling the unfolded dimensions of sheet metal, including the modeling and unfolding methods of large arc sheet metal parts, bend deduction method, etc .

In this example T= Thickness of the sheet R= Internal Bend Radius L= Flat Length of the bend δ= Distance between the inside radius of the bend and the neutral axis N= Neutral Axis. When a sheet metal forms a bend, the inner portion ( Covered by δ) is always in compression which reduces the part length. On the other hand, the outer portion ( Covered by . The value of the bend allowance from sheet metal suppliers, manufacturers, and engineering textbooks is provided in bend tables. A bend table looks like the following Excel spreadsheet. . The bend allowance calculation formula with the K-factor is shown below: BA = 2πA(R+KT)/360. π=3.14; A=Angle (degrees) R=Bend Radius;

The bend allowance and bend deduction are two measures that relate the bent length of a piece of sheet metal to the flat length. The bend allowance describes the length of the neutral axis between the bend lines, or in other words, the arc length of the bend. Therefore, the bend allowance added to the flange lengths is equal to the total flat .

stainless steel bend deduction chart

sheet metal flat length calculator

$215.99

sheet metal bend deduction formula|sheet metal blank size calculator