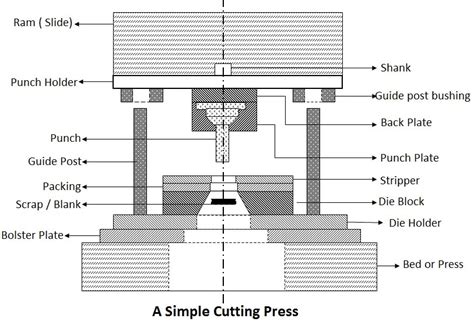

sheet metal bending process pdf Deep (or cup) drawing: In this operation, forming of a flat metal sheet into a hollow or concave shape like a cup, is performed by stretching the metal in some regions. A blank-holder is used to clamp the blank on the die, while the punch pushes into the sheet metal. The sheet is drawn into the die hole taking the shape of the cavity. Drill Size & Decimal Equivalents Fract Size Decimal Inches # Size Letter Size Metric Size Fract Size Decimal Inches # Size Letter Size Metric Size 0.0135 80 1/4 0.250 E 79 0.2559 6.5 1/64 0.0156 .

0 · sheet metal stamping process pdf

1 · sheet metal operations with diagrams

2 · sheet metal manufacturing process pdf

3 · sheet metal forming process pdf

4 · sheet metal fabrication handbook pdf

5 · sheet metal design calculations pdf

6 · sheet metal calculations pdf

7 · sheet metal calculation formula pdf

There are many different sizes of purpose-built ceiling fan boxes out there, available even at your local hardware store. In addition to the standard round form factor, you may also find them in an octagon shape. Regardless of .

Bend Radius - As a rule, inside bend radius should be equal to material thickness. When the radius is less than recommended, this can cause material flow problems in soft material and .

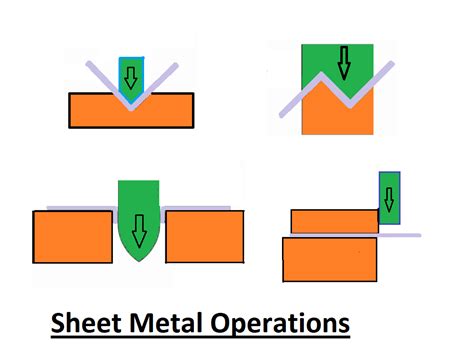

Sheet bending is defined as the straining of the metal around a straight axis. During bending operation, the metal on the inner side of the neutral plane is compressed, and the metal on the .

sheet metal stamping process pdf

sheet metal operations with diagrams

Deep (or cup) drawing: In this operation, forming of a flat metal sheet into a hollow or concave shape like a cup, is performed by stretching the metal in some regions. A blank-holder is used to clamp the blank on the die, while the punch pushes into the sheet metal. The sheet is drawn into the die hole taking the shape of the cavity.It is a process of cold forming a flat blank of sheet metal into a hollow vessel without much wrinkling, trimming, or fracturing. The process involves forcing the sheet metal blank into a die cavity with a punch. The punch exerts sufficient force and the metal is drawn over the edge of the die opening and into the die, Fig 6.4. InBending Process - Free download as Word Doc (.doc), PDF File (.pdf), Text File (.txt) or read online for free. There are several types of bending processes: 1) Air bending involves the punch touching the workpiece but not bottoming out, .DOI: 10.1016/S0278-6125(98)80002-2 Corpus ID: 11524385; Automated process planning for sheet metal bending operations @article{Gupta1998AutomatedPP, title={Automated process planning for sheet metal bending operations}, author={Satyandra K. Gupta and David A. Bourne and K. H. Kim and Sivaraj Sivarama Krishnan}, journal={Journal of Manufacturing Systems}, .

Int J Adv Manuf Technol DOI 10.1007/s00170-016-8823-x ORIGINAL ARTICLE Sheet-metal bend sequence planning subjected to process and material variations Zahid Faraz 1 & Syed Waheed ul Haq 1 & Liaqat Ali 2 & Khalid Mahmood 1 & Wasim Akram Tarar 1 & Aamer Ahmed Baqai 1 & Mushtaq Khan 2 & Syed Husain Imran 2 Received: 5 January 2016 / Accepted: 25 April 2016 .ABB IRB 2400/16 is the assigned robotic welding equipment used in GMAW process while sheet metal bending machine SUNFLUID 800/2007 is utilized for sheet metal bending process.Sheet metal is available in flat pieces or coiled strips. The coils are formed by running a continuous sheet of metal through a roll slitter. The thickness of sheet metal is commonly specified by a traditional, non-linear measure known as its gauge. The larger the gauge number, the thinner the metal. Commonly A Finite Element (FE) 3D model of both the roll-bending machine and the metal sheet is used to simulate the mechanical behaviour of the metal sheet during the forming process, checking for the .

Introduction In sheet metal bending process, a sheet metal blank is plastically deformed between tools (dies) to obtain the desired final configuration. It plays a significant role in automobile industries, aerospace industries to manufacture the curved parts, in production of various items used in daily life, as well as in the construction of . Download full-text PDF Download . a die shape optimization method for reduction of spring back defect due to elastic recovery behaviour in Sheet metal bending process is presented by using the .SHEET METALWORKING - Michigan State University

PDF | Abstract- Spring back is the main defect in sheet metal bending process. The spring back of sheet metal bending, which is defined as elastic. | Find, read and cite all the research you . Bending is one of the most common sheet metal fabrication operations. Also known as press braking, flanging, die bending, folding and edging, this method is used to deform a material to an angular shape.. This is done through the application of force on a workpiece. The force must exceed the material’s yield strength to achieve plastic deformation.Sheet-Metal Forming Processes Process Roll forming Stretch forming Drawing Stamping Rubber-pad forming Spinning Superplastic forming Peen forming Explosive forming Magnetic-pulse forming Characteristics Long parts with constant complex cross-sections; good surface finish; high production rates; high tooling costs.

INSTITUIÇÕES DO PROCESSO CIVIL DO BRASIL , 2024. A Coleção Clássicos de Processo Civil em Domínio Público organizada pelos professores Antônio Pereira Gaio Júnior, Bruno Augusto Sampaio Fuga e William Santos Ferreira .The document discusses various sheet metal working processes including cutting operations like shearing, blanking, and punching and describes how they work. It also covers bending operations and explains that bending plastically deforms .Request PDF | On Nov 1, 2016, Hsien-I Lin and others published Automatic following in a sheet metal bending process | Find, read and cite all the research you need on ResearchGateCNC sheet metal bending is one of the most underrated processes available for sheet metal part production. With bending, it’s possible to produce a wide variety of part geometries without tooling, at fast lead times, with high levels of repeatability and through automated processes.

sheet metal manufacturing process pdf

sheet metal company for bending process. They have used Ishikawa diagram for root cause analysis of sheet metal bending process problems and implemented FMEA procedure successfully. M.Dudek-Burlikowska[3] have suggested integration of quality management and quality control system for success of companies.• BENDING/UNBENDING: This is a cyclic deformation (most often associated with plane strain). It is found on the die entry line as well as in drawbeads. • STRETCH-AND-BEND: This mode is associated to flanging operations for which . Introduction to sheet metal forming processes .Bending Process - Free download as PDF File (.pdf), Text File (.txt) or read online for free. This document outlines guidelines and information for a sessional course on metal forming and sheet metal working. It discusses general guidelines for experiments, report requirements, and grading. It also provides information on sheet metal, common forming processes like bending and .Surface condition of sheet : Depends on rolling practice; important in sheet forming as it can cause tearing and poor surface quality Classification of sheet metal working processes Sheet metal Shearing Bending Drawing The term "shearing or cutting process" is refers to a specific cutting process that produces straight line cuts to separate a .

The ability to bend a metal without cracking at the bend improves when the bend is made across the “metal grain” (i.e., the line of the bend is perpendicular to the rolling direction of the sheet). The largest possible bend radius should be used in design to prevent cracking, and the bend radius should not be less than the sheet thickness t.10 Combined bending and tension of sheet 136 10.1 Introduction 136 10.2 Stretching and bending an elastic, perfectly plastic sheet 136 10.3 Bending and stretching a strain-hardening sheet 142 10.4 Bending a rigid, perfectly plastic sheet under tension 144 10.5 Bending and unbending under tension 145 10.6 Draw-beads 150 10.7 Exercises 151 11 .

Sheet Metal Unfold Rule Equations. Register for more free training on this topic at KETIV Virtual Academy. Register Now. Free training, every week, from real experts. 9HUVLRQ 1R 3DJH RI .(7,9 $ &RQWHQWV

10 Combined bending and tension of sheet 136 10.1 Introduction 136 10.2 Stretching and bending an elastic, perfectly plastic sheet 136 10.3 Bending and stretching a strain-hardening sheet 142 10.4 Bending a rigid, perfectly plastic sheet under tension 144 10.5 Bending and unbending under tension 145 10.6 Draw-beads 150 10.7 Exercises 151 11 .PDF | On Jan 1, 2016, Christian Zehetner and others published EFFICIENT NUMERICAL SIMULATION OF INDUSTRIAL SHEET METAL BENDING PROCESSES | Find, read and cite all the research you need on ResearchGate

sheet metal forming process pdf

sheet metal fabrication handbook pdf

sheet metal design calculations pdf

sheet metal calculations pdf

Some fixtures don’t require a mounting bracket. The fixture has its own junction box; once inserted into a hole cut in the ceiling, the fixture is supported by the ceiling. Integral clips and trim pieces pull the fixture tightly to the plaster or drywall ceiling.A junction box is not a special type of box but any standard electrical box used to enclose wire splices. The most commonly used box for junctions is a 4-inch square box (either metal or strong plastic), which offers ample space for making wire connections with multiple .

sheet metal bending process pdf|sheet metal stamping process pdf