proper screw spacing for sealing metal box Proper screw spacing varies depending on the specific type of metal roofing panel and the manufacturer’s recommendations, but in general, screws should be spaced about 12 . Shop for metal palettes and watercolor boxes for holding half pans,full pans and tubes. Handy for travelling watercolorists. Lowest online prices guaranteed.

0 · screw size for metal roofing

1 · screw placement for metal roof

2 · metal roofing screw spacing

3 · how many screws for metal roofing

NEWMAR WATERPROOF JUNCTION BOX MEDIUM | Marine Electronics Unlimited. Skip to content. Next Day Shipping On Most Items with 8 Warehouses. Lifetime technical support on all your purchases. Price Matching on All .

Proper screw spacing is vital for the installation of metal roofing. The spacing and placement of screws vary based on different metal roofing profiles. Follow the manufacturer’s recommendations for screw spacing to ensure a secure and durable metal roof.Discover the proper screw spacing for metal roofing to ensure durability and leak . Proper screw spacing varies depending on the specific type of metal roofing panel and the manufacturer’s recommendations, but in general, screws should be spaced about 12 . Properly spaced screws help create a tight seal between the metal panels and the roof deck. This reduces the risk of leaks, which can occur if panels are not secured correctly or if screws are too far apart, allowing for gaps and .

The most common types of fasteners used for metal roofing installations are nails, rivets, screws, clips, and cleats. Most installations will use a variety of each of these types of fasteners. . On average, screw spacing should be between 12-24 inches apart depending on panel length and thickness. Another factor that affects proper screw placement is wind uplift resistance requirements in your area. Local building . Properly placed screws help create a secure seal between the metal panels and the roof deck, preventing water infiltration and reducing the risk of leaks. This is particularly important in areas prone to heavy rainfall or snow. .Hip flashing should be used when the roof panels change pitch. Place the hip flashing over the lower roof panels. Large tab closure or universal closure should be placed between the lower .

It’s very important to seat each screw such that it’s straight and flush in order to create the proper washer seal. Sometimes folks can get in a hurry (there are thousands of screws to fasten, after all!), and if you’re not careful, you can end . Discover the proper screw spacing for metal roofing to ensure durability and leak prevention. Perfect your project with our expert guide on spacing screws.

screw size for metal roofing

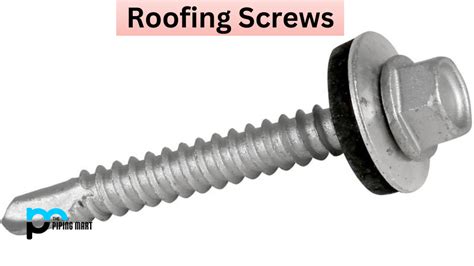

Why is screw spacing important? Proper metal roofing installation begins with the use of the right equipment, starting with the screws used to anchor your panels to the structure. You must make sure you are placing the screws in the .Proper screw spacing is crucial for drywall panels. Learn how to achieve a professional-grade installation with this definitive guide . To ensure a robust drywall installation, it’s crucial to pinpoint the optimal screw spacing. For metal framing, employ 8-inch intervals on edges and 12 inches in the field, whereas drywall screws can be . Self-Drilling Screws. Function: Self-drilling screws have a drill bit-like tip that allows them to create their own hole in the metal, eliminating the need for pre-drilling. Advantages: They are quick to install and provide a tight seal. . Screw Spacing For Corrugated Metal Roofing. When installing corrugated metal roofing, proper screw spacing is crucial. To prevent leaks and ensure stability, place screws at every corrugation. This means securing them in the valleys, not just on the ridges. Maintaining a consistent spacing of 24 inches between screws is recommended.

At first glance, it seems that we might be able to use as few as six fasteners on the box if we use the LS-04 gasket. However, we must consider that the corners require tighter spacing than the straight portions of the box. So, on the straight sections, we can use the calculated spacing, while making sure that the corners are adequately secured.Putting a metal roof on a cabin with a 4:12 pitch. Each side is only 1 10ft sheet long and 8 sheets wide. . As far as spacing vertically up the sheet, strap the roof 24” on center (i use 1x6 rough sawn for a nice flat roof) and that’s where you drill your holes. After you strap it, have a guy hook his tape on the ridge and call out .

Proper screw spacing plays a vital role in maintaining the structural integrity of the roof. By evenly distributing the load across the roof panels, screws help prevent the metal sheets from shifting, 386-222-6779. [email protected]. SHOP NOW. . Additionally, correct spacing ensures that the washers adequately seal around each screw . Selecting the correct type of screw is vital for both the integrity and longevity of a corrugated metal roof. Self-tapping screws are ideal, as they can drill their own holes into metal, reducing installation time. The industry typically favors galvanized screws for their resistance to rust and corrosion. These screws often come with rubber or neoprene washers that create a . Screw spacing on metal roofs is critical for several reasons:. Structural Integrity: Proper screw spacing ensures that the metal panels are securely attached to the underlying structure.Incorrect spacing can lead to panel movement, which may result in leaks or damage. Weather Resistance: Adequate spacing helps prevent issues caused by extreme weather .

Custom CNC Machined Enclosures. If you’re looking for an enclosure that can be immersed in water, this is it. A CNC machined enclosure can be designed to meet NEMA Types 1, 2, 4(X) and 5. It can also be completely sealed, and with the proper O-rings or gaskets, made waterproof, sufficient to protect against deep liquid immersion and thereby meeting NEMA . Metal-to-wood screws, metal-to-metal screws, sealing tape, and lap screws are all commonly used in metal roofing installation. . On average, screw spacing should be between 12-24 inches apart, depending on panel length and thickness. . When it comes to preventing leaks on your metal roof, proper screw placement and sealing are crucial. Make .Always hook your wires so the hook goes in the direction the screw tightens. That way it will tighten with the screw. If you do the opposite way the tightening of the screw actually loosens the hook. Typically this means the hook end is on bottom for right side screw terminals and top for left side screw terminals.

A row of screws is called a screw line. The screws are spaced so that one screw is on every third corrugation. A standard corrugated panel is usually 37″ wide, while 39″ wide panels add additional corrugations. Therefore, you’ll find four screws per sheet for a 37-inch wide panel. If you buy a 39″ wide sheet of metal roofing, four .How to know the correct hole size and spacing required to mount sheet metal on hard plastic? (or generally any 2 materials) . This raises a bunch of other points about how to ensure a good water seal, but since you didn't ask about the water sealing aspect specifically, I've leave it up to you if that's something you need or want guidance on .

screw placement for metal roof

The metal electrical box says it's "Acceptable for fan support when secured with 10-32 screws provided". The box has 2 black screws (sheetrock screws?) in the middle that are screwed to some piece of wood above it. The .

Gasket Compression and Fastener Spacing Design Equation and Calculator. General Engineering Reviews Engineering Applications and Design. Proper cover - gasket compression design by application of spaced fasteners is a function .

Spacing recommendation for SnoBar and ColorBar snow rails on a screw-down roof. 717-697-1999; . Screw Down SnoBar and ColorBar Spacing Guidelines. . Our approach to proper placement includes full patterns of snow guards across the entire roof surface to prevent snow and ice from moving in the first place. When frozen precipitation loses its .It’s essential to use screws specifically designed for metal roofing, which typically feature rubber washers to create a watertight seal. Inconsistent Screw Spacing: Uniform screw spacing is crucial for even distribution of pressure and secure attachment of the panels. Follow manufacturer guidelines for spacing to avoid issues.Place a #10 x 1-1/2” screw next to this rib, into a roof purlin, and continue screw placement every nine inches across the roof. The exception will be at the eave and the ridge, as this is where the greatest shear forces are. At these locations use either a diaphragm screw or a #14 x 1-1/2” screw on both sides of every high rib.Determining the Correct Spacing. Ensuring the right spacing between screws is paramount for the stability and longevity of metal roofing. The correct spacing ensures uniform weight distribution and minimizes the risk of sheets becoming dislodged in inclement weather. Edge Spacing. The edges or the perimeter of the roof are particularly vulnerable.

Follow Manufacturer Guidelines: Adhere to the specific screw spacing and placement patterns recommended by the metal panel manufacturer to ensure proper load distribution and sealing. Pre-Drill Holes: For thicker metal panels, pre-drilling can prevent splitting and ensure screws are inserted straight.

The Florida metal roof screw pattern is a critical element in ensuring a secure and wind-resistant metal roof installation. Enhance roof wind resistance with manufacturer’s guidelines, wind zone considerations, proper screw spacing, placement, and attention to . We discuss the proper amount and spacing for screws. We also discuss where to locate the metal roofing screws for: ⅞” Corrugated, R Panel, and 7.2 Panel. . Lap screws are connected at 12” to 18” on center and butyl tape seal is used at the panel sidelap. . Screw Line Spacing For Metal Roofing Sitting On A Solid Wood Substrate. It can be confusing trying to figure out the correct way to screw down a metal roof. You do not know where to put the screws, how often to fasten the metal roofing panels, and then you have to figure out .

Screw Placement: Screws penetrate the metal panel and underlying structure, creating a tight seal. Metal Shingles: Blending Style and Durability. . Proper screw spacing balances holding power with material integrity. Too close, and you risk damaging the panels; too far apart, and you compromise wind uplift resistance. . 1) The screw heads for the box mounting tabs stick out back the rest of the dimples on the back of the box. Consequently, this makes the top-right and bottom-left diagonals where the mounting tabs are tight to the wall, but then leaves a big enough gap behind the other two diagonals to allow the box to "rock".

metal roofing screw spacing

how many screws for metal roofing

Fibox plastic waterproof control panel boxes are designed to house and protect electronic controls & components in the harshest environments, indoors and out.

proper screw spacing for sealing metal box|screw placement for metal roof