cnc machine centre Haas Automation’s complete line of CNC turning centers is designed to meet the needs of modern machine shops – now and long into the future. CHUCK SIZE | BAR CAPACITY | WORK . CNC machining is a manufacturing process that uses computerized controls to operate and manipulate machine tools, shaping a variety of materials into custom parts and designs. There are several types of CNC machines, each with specific capabilities and applications.

0 · turning lathe machine

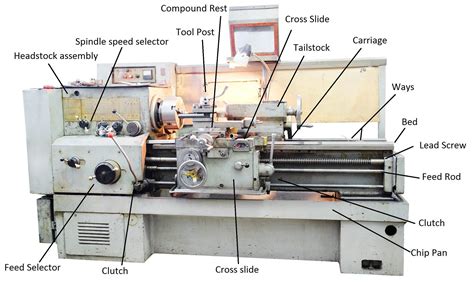

1 · parts of cnc lathe machine

2 · lathe vs turning machine

3 · cnc turning machine

4 · cnc turning lathe machine

5 · cnc milling and turning

6 · cnc machining center price

7 · cnc machine center

## What is a Solar Panel Junction Box? A solar panel junction box is a crucial component of a solar panel system. It connects electrical components in the solar panel. It ensures that the generated electricity is distributed. The .

turning lathe machine

metallic blue velvet fabric

parts of cnc lathe machine

Our affordable, flexible and precise CNC machine centres is the right woodworking machine for every professional. Request your free quote now!Different optimisation levels ensure shorter process times, different milling results .Haas Automation’s complete line of CNC turning centers is designed to meet the needs of modern machine shops – now and long into the future. CHUCK SIZE | BAR CAPACITY | WORK .

Okuma has horizontal and vertical machining centers, including 5-axis machines, in a variety of sizes and configurations to meet any manufacturing needs.The Makino commitment starts with global leadership in metal-cutting and manufacturing technology, with industry-leading CNC Machining Centers - horizontal machining centers, vertical machining centers, wire EDM and Ram . CNC turning centers are essential for precision machining, offering high accuracy and efficiency in producing cylindrical parts. Understanding the components, operation, and .

With decades of hands-on experience and a focus on cutting-edge CNC technology, Kitamura Machinery delivers machining centers that offer improved productivity, easy adaptability, reduced defects and precise, reliable long-term . The term machining center describes a CNC milling and drilling machine that includes an automatic tool changer and a table that clamps the workpiece in place. Types .

metallic box clamp

Find a large selection of new & used CNC Machining Centers for sale at MachineSales.com. Buy machinery and equipment from leading dealers across America. We’ll learn about the definition of CNC turning center, how to differentiate CNC turning center from a CNC lathe, plus the types, basic configuration, and advantages.The elumatec offering includes a broad range of models for CNC machining, designed to work with aluminium, steel and PVC profile bars. Depending on the type, each machine can operate on 3, 4 or 5 axes according to the specific .Okuma has horizontal and vertical machining centers, including 5-axis machines, in a variety of sizes and configurations to meet any manufacturing needs.

Our vertical, horizontal, and 5-axis machining centers combine stability, power, and accuracy with our proven technologies. Okuma’s machining centers are thoughtfully designed to manufacture high-precision parts and deliver impressive metal removal rates. View All Machining Centers.Our MU-6300V 5-axis vertical machining center achieves high efficiency and high productivity in 5-axis, multi-sided machining. This CNC vertical machining center's highly rigid and accurate double column structure and low center of gravity in workpiece movement (trunnion table) enable both heavy-duty cutting and high-speed finishing.Our LU35II CNC turning center is the latest evolution of our large 4-axis turning centers. Two turrets offer dramatic improvements in process flexibility and cycle time when compared to 2-axis machines. The LU35 II has 22 tool stations, two independent saddles, four power ranges, large hardened box guide ways, a live quill tailstock, and our .

5-Axis machines are advanced computer numerical control (CNC) machines that allow cutting tools to move simultaneously around five axes (sides) of an object or part for high-precision, intricate cutting and shaping.

This CNC machine guide will provide insight on what a horizontal machining center is, how it works and why you need one in your shop.

Okuma's double column machining centers come in a variety of sizes and bed lengths, providing accuracy and stability suitable for many industries.

The MA-8000H horizontal machining center delivers high productivity without compromising on accuracy. This machine effectively handles a wide range of workpieces from the heavy-duty cutting of steel to aluminum machining. A wide range of spindles offers full power from low to high revolution speed. And for extremely high accuracy, Okuma’s .

Our MB-5000HII is a high-speed, thermally-stable horizontal machining center that offers quick acceleration, short tool changes, and high power to improve productivity.Our MA-500HII horizontal machining center achieves everything from highly accurate, steady machining of mass production to long, continuous die/mold applications.Okuma has horizontal and vertical machining centers, including 5-axis machines, in a variety of sizes and configurations to meet any manufacturing needs.Our vertical, horizontal, and 5-axis machining centers combine stability, power, and accuracy with our proven technologies. Okuma’s machining centers are thoughtfully designed to manufacture high-precision parts and deliver impressive metal removal rates. View All Machining Centers.

Our MU-6300V 5-axis vertical machining center achieves high efficiency and high productivity in 5-axis, multi-sided machining. This CNC vertical machining center's highly rigid and accurate double column structure and low center of gravity in workpiece movement (trunnion table) enable both heavy-duty cutting and high-speed finishing.

Our LU35II CNC turning center is the latest evolution of our large 4-axis turning centers. Two turrets offer dramatic improvements in process flexibility and cycle time when compared to 2-axis machines. The LU35 II has 22 tool stations, two independent saddles, four power ranges, large hardened box guide ways, a live quill tailstock, and our .5-Axis machines are advanced computer numerical control (CNC) machines that allow cutting tools to move simultaneously around five axes (sides) of an object or part for high-precision, intricate cutting and shaping.This CNC machine guide will provide insight on what a horizontal machining center is, how it works and why you need one in your shop.

Okuma's double column machining centers come in a variety of sizes and bed lengths, providing accuracy and stability suitable for many industries.The MA-8000H horizontal machining center delivers high productivity without compromising on accuracy. This machine effectively handles a wide range of workpieces from the heavy-duty cutting of steel to aluminum machining. A wide range of spindles offers full power from low to high revolution speed. And for extremely high accuracy, Okuma’s .

Our MB-5000HII is a high-speed, thermally-stable horizontal machining center that offers quick acceleration, short tool changes, and high power to improve productivity.

Square boxes are also commonly used as junction boxes, which can be installed in ceilings or walls to support lighting fixtures, light switches, or receptacles.

cnc machine centre|parts of cnc lathe machine