cnc machine components The tailstock quill is situated in the tailstock, the quill has a conical end that is collinear with the spindle and chuck axis. When machining a . See more Waterproof IP68 External Junction Box, 2 Way Plug Line M20 Coaxial Cable Connector Wire Range 5 to 15mm Outdoor External Electric Power Cord Boxes (Black-2pcs)

0 · schematic diagram of cnc machine

1 · parts made by cnc machine

2 · main parts of cnc machine

3 · diagram of cnc lathe machine

4 · cnc machine tool components

5 · cnc machine parts diagram

6 · cnc machine components list

7 · block diagram of cnc machine

vigoro 3 in 1 metal plant bracket installation. Providing all your Commercial, Residential Estate, Garden Solutions and Related Lawn Care Needs and Services in Naples Florida. Our mission at Rise Landcare is to provide high quality services efficiently, while promoting cooperation and equitable use of the earth's natural resources.

The headstock is a section unique to a lathe that contains the main drive, bearings, and gears needed to rotate the chuck at the required speeds for machining. The headstock can be found on the left-hand side of a CNC lathe. The headstock is usually enclosed and is accessed via removable inspection panels. See more

The tailstock is a CNC lathe component that is used to axially support long, cylindrical workpieces on one side while the chuck supports . See moreThe tailstock quill is situated in the tailstock, the quill has a conical end that is collinear with the spindle and chuck axis. When machining a . See more

The chuck is a lathe-specific part that is used to grip the raw material while it is being machined on a lathe. It is rotated at high speed by the spindle. A chuck typically has three or four pneumatically or hydraulically actuated grips. Three-jaw chuck grips are self . See more

Foot pedals are used to activate and deactivate the chuck and tailstock quill of a CNC lathe. Foot pedals help operators load blanks and unload completed parts from the machine. . See more CNC machines consist of several key components and elements that contribute to their functionality and efficiency. Here, we will explore the . Components of a CNC Machine. The main parts of the CNC machine are: (i) Input Devices: These devices are responsible for inputting the part program into the CNC machine. There are three commonly used input . Understand the parts and functions of CNC machines. From controllers and motors to tool holders and coolant systems, get a detailed explanation of each component to enhance your knowledge.

CNC machines are complex assemblies and have many components, but there are 13 key components that you should be familiar with. These key components fall into two categories: the control system and the . Different parts of the CNC machine, such as spindles or tool changers, can quickly create parts from raw materials. The machine follows orders from a computerized system that directs the machine tools to perform .

Parts of a CNC milling machine include a column, base, knee, power feed mechanism, a work table, ram, spindle, milling tool, milling chuck, CNC controller, and an overhanging arm along with arbor support in case of .

schematic diagram of cnc machine

parts made by cnc machine

cnc machinery turning parts manufacturer

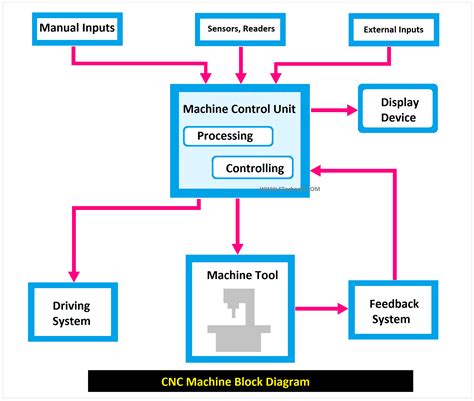

What are the Parts of a CNC Machine? Bed: Typically constructed from cast iron for enhanced durability and strength, the bed is the machine’s foundation, supporting all components. Spindle: Inside the machining area, the electrically . Three fundamental parts make up a computer numerical control (CNC) system: processing apparatus, often known as a machine tool, a machine control unit, and CNC software, which is a set of instructions. This article will describe the different parts of a CNC machine. Some parts are common between lathes and mills, like the control unit, driving system, and feedback system, while others are specific to a certain type of machine.

CNC machines consist of several key components and elements that contribute to their functionality and efficiency. Here, we will explore the primary parts of CNC machines and the elements they incorporate. With this CNC machine guide, we will talk about the the components that make up CNC machine tools deeply, unveiling how they collaboratively create precision, efficiency, and astonishing manufacturing wonders. CNC machines are complex assemblies and have many components, but there are 13 key components that you should be familiar with. These key components fall into two categories: the control system and the machine system.

Different parts of the CNC machine, such as spindles or tool changers, can quickly create parts from raw materials. The machine follows orders from a computerized system that directs the machine tools to perform specific movements and operations according to a pre-programmed design.In this article, we will explore the main parts of a CNC machine and explain the CNC block diagram in simple terms. 7 Key Components of a CNC Machine 1. Machine Control Unit (MCU) The Machine Control Unit is the brain of the CNC machine.

CNC machines perform incredible tasks that efficiently produce intricate components, surpassing traditional machining methods in both precision and cost-effectiveness. In this article, we’ll take a high-level look at CNC machine parts and functions.

Parts of a CNC milling machine include a column, base, knee, power feed mechanism, a work table, ram, spindle, milling tool, milling chuck, CNC controller, and an overhanging arm along with arbor support in case of horizontal milling machines. Three fundamental parts make up a computer numerical control (CNC) system: processing apparatus, often known as a machine tool, a machine control unit, and CNC software, which is a set of instructions.In selecting the appropriate material for your CNC machined part, it is crucial to thoroughly evaluate various factors, including cost, part weight, electrical conductivity, heat resistance, surface finish, and the intended application of the component. Furthermore, the machinability of different materials varies significantly.

Understand the parts and functions of CNC machines. From controllers and motors to tool holders and coolant systems, get a detailed explanation of each component to enhance your knowledge. Components of a CNC Machine. The main parts of the CNC machine are: (i) Input Devices: These devices are responsible for inputting the part program into the CNC machine. There are three commonly used input devices: punch tape reader, magnetic tape reader, and computer via RS-232-C communication. CNC milling is a subtractive manufacturing process that uses computer-controlled machines to remove material from a workpiece to create the desired shape. This process is highly precise and can produce complex parts with tight tolerances. Learn about the precision, automation, and versatility that make CNC machines essential for high-quality production. From the basics of how they operate to their advantages over traditional tools, discover why CNC technology is the .

CNC or computer numerical control is an NC system that employs a dedicated microcomputer as a machine control unit. The presence of a microprocessor, RAM, ROM, and input and output devices has increased the level of automation in NC systems.

What is CNC: CNC stands for computer numerical control, which is a process of using computer software to control the movement and operation of machines that can cut, carve, or engrave materials. Types of CNC machines : There are different types of CNC machines, such as routers, mills, lathes, lasers, and plasma cutters. CNC machining allows for the rapid but highly accurate construction of projects from materials that are not suited to other types of rapid prototyping manufacturing, such as 3D printing. In this article, we’ll be taking a deep dive into CNC machining to create a complete guide to this cutting-edge process.

CNC machinery is responsible for producing everything from washers and razor blades to parts for complex aerospace applications such as flight decks, airframes and component housings for electronics. A CNC cutting machine, for example, can be used for cutting a variety of different materials ranging from wood to steel.Learn how to prepare, get a quote & source custom CNC machined parts in 3 simple steps. A list of useful resources for those who want to delve deeper. What is CNC machining? What are the different types of CNC machines? How do they work?

CNC stands for Computer Numerical Control and refers to the automated control of machining tools, such as drills, lathes, mills, grinders, routers, and 3D printers, using a computer. The CNC machining process involves inputting coded instructions into a computer, which translates the code into precise movements for the cutting tools.

"Discover how CNC machining is revolutionizing metal part production. From 3D CAD designs to flawless metal components, this video covers the essential techn. This article will describe the different parts of a CNC machine. Some parts are common between lathes and mills, like the control unit, driving system, and feedback system, while others are specific to a certain type of machine.CNC machines consist of several key components and elements that contribute to their functionality and efficiency. Here, we will explore the primary parts of CNC machines and the elements they incorporate.

With this CNC machine guide, we will talk about the the components that make up CNC machine tools deeply, unveiling how they collaboratively create precision, efficiency, and astonishing manufacturing wonders. CNC machines are complex assemblies and have many components, but there are 13 key components that you should be familiar with. These key components fall into two categories: the control system and the machine system. Different parts of the CNC machine, such as spindles or tool changers, can quickly create parts from raw materials. The machine follows orders from a computerized system that directs the machine tools to perform specific movements and operations according to a pre-programmed design.In this article, we will explore the main parts of a CNC machine and explain the CNC block diagram in simple terms. 7 Key Components of a CNC Machine 1. Machine Control Unit (MCU) The Machine Control Unit is the brain of the CNC machine.

cnc machined v8 engine block

CNC machines perform incredible tasks that efficiently produce intricate components, surpassing traditional machining methods in both precision and cost-effectiveness. In this article, we’ll take a high-level look at CNC machine parts and functions. Parts of a CNC milling machine include a column, base, knee, power feed mechanism, a work table, ram, spindle, milling tool, milling chuck, CNC controller, and an overhanging arm along with arbor support in case of horizontal milling machines. Three fundamental parts make up a computer numerical control (CNC) system: processing apparatus, often known as a machine tool, a machine control unit, and CNC software, which is a set of instructions.

In selecting the appropriate material for your CNC machined part, it is crucial to thoroughly evaluate various factors, including cost, part weight, electrical conductivity, heat resistance, surface finish, and the intended application of the component. Furthermore, the machinability of different materials varies significantly.

Understand the parts and functions of CNC machines. From controllers and motors to tool holders and coolant systems, get a detailed explanation of each component to enhance your knowledge. Components of a CNC Machine. The main parts of the CNC machine are: (i) Input Devices: These devices are responsible for inputting the part program into the CNC machine. There are three commonly used input devices: punch tape reader, magnetic tape reader, and computer via RS-232-C communication. CNC milling is a subtractive manufacturing process that uses computer-controlled machines to remove material from a workpiece to create the desired shape. This process is highly precise and can produce complex parts with tight tolerances. Learn about the precision, automation, and versatility that make CNC machines essential for high-quality production. From the basics of how they operate to their advantages over traditional tools, discover why CNC technology is the .

CNC or computer numerical control is an NC system that employs a dedicated microcomputer as a machine control unit. The presence of a microprocessor, RAM, ROM, and input and output devices has increased the level of automation in NC systems. What is CNC: CNC stands for computer numerical control, which is a process of using computer software to control the movement and operation of machines that can cut, carve, or engrave materials. Types of CNC machines : There are different types of CNC machines, such as routers, mills, lathes, lasers, and plasma cutters.

CNC machining allows for the rapid but highly accurate construction of projects from materials that are not suited to other types of rapid prototyping manufacturing, such as 3D printing. In this article, we’ll be taking a deep dive into CNC machining to create a complete guide to this cutting-edge process.CNC machinery is responsible for producing everything from washers and razor blades to parts for complex aerospace applications such as flight decks, airframes and component housings for electronics. A CNC cutting machine, for example, can be used for cutting a variety of different materials ranging from wood to steel.Learn how to prepare, get a quote & source custom CNC machined parts in 3 simple steps. A list of useful resources for those who want to delve deeper. What is CNC machining? What are the different types of CNC machines? How do they work?CNC stands for Computer Numerical Control and refers to the automated control of machining tools, such as drills, lathes, mills, grinders, routers, and 3D printers, using a computer. The CNC machining process involves inputting coded instructions into a computer, which translates the code into precise movements for the cutting tools.

main parts of cnc machine

A true reflection of the typical know-how of the House, the Veuve Clicquot Brut Champagne (Veuve Clicquot Yellow Label) is made from a blend of 50 to 55% Pinot Noir, 28 to 33% Chardonnay and 15 to 20% of Pinot Meunier. The gift box.

cnc machine components|main parts of cnc machine