maximum axis in cnc machine In this comprehensive guide to CNC machine axes, we have explored the fundamentals of each axis, their functions, and applications in the realm of CNC machining. By understanding the . Wiremold Ratchet-Pro Series Floor Box provides single- and dual-service capability in a variety of easy-to-install round floor boxes. These designs allow the flexibility for providing power, A/V or communication services to open-space areas in an aesthetic solution.

0 · what is 5 axis machining

1 · cnc mill axis diagram

2 · cnc machine axis identification

3 · cnc axis explained

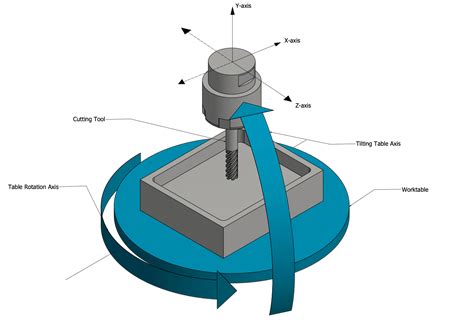

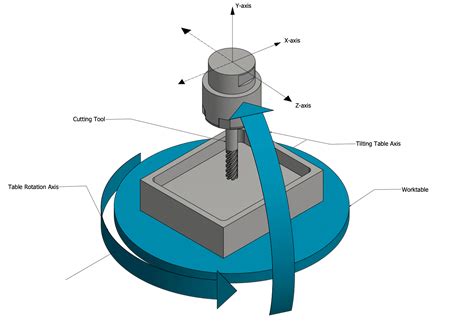

4 · 4 axis cnc milling machine

5 · 4 axis cnc mill

6 · 3 axis cnc milling machine

7 · 12 axis cnc machine

I installed a spa sub-panel on the exterior of my house. The inside wiring is NM-B 6AWG cable that goes to a junction box where it's spliced to 6AWG direct bury cable (the NM-B wire I had wasn't long enough, so it was cheaper to splice). The splice was done with split bolts, wrapping 3M Temflex rubber splicing tape, then wrapped in electrical tape.

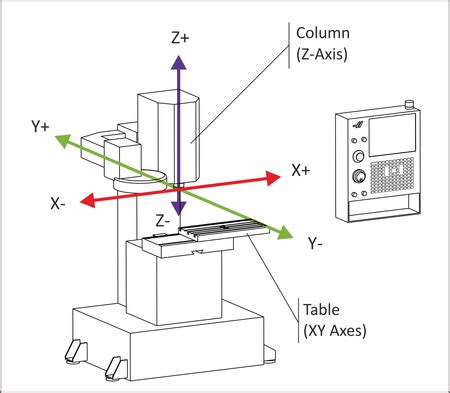

A standard 3-axis CNC milling machine has a table that moves the part to provide one or two planes of movement and a tool that provides the other one or two planes of movement. 3-axis .In this comprehensive guide to CNC machine axes, we have explored the fundamentals of each axis, their functions, and applications in the realm of CNC machining. By understanding the . The number and type of axes dictate the complexity of parts the machine can produce. Here’s a quick look into the most common CNC machine axis layouts—3-axis, 4-axis, and 5-axis—and see how they stack up. The 3 .While traditional CNC machines typically operate with three axes (X, Y, and Z), multi-axis machines can have up to six or more axes. This allows for increased flexibility and complexity in machining operations.

Axes of a CNC milling machine. Taking the most common vertical CNC mills as an example, 3 axes control the linear motion of the workpiece and the spindle, the X axis moves left and right, the Y axis moves forward and . Many complex and practical shapes can be manufactured by 3-axis CNC milling, especially when in the hands of a world-class CNC machining facility. 3-axis machining is best suited to manufacture of planar milled profiles, .

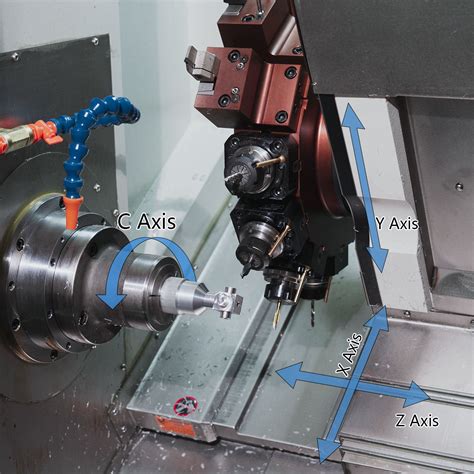

X-axis: Horizontal movement (left to right). Y-axis: Horizontal movement (front to back). Z-axis: Vertical movement (up and down). These three axes are sufficient for simple parts, but when it comes to complex geometries and designs, multi . In this complete guide to 4 Axis CNC Machining, you’ll learn when to use one, how they work, 4 Axis CNC workholding, Programming, and 4 Axis for CNC Routers.With a maximum axis configuration, CNC machines have the ability to perform complex machining operations with enhanced precision. The additional axes enable the cutting tool to approach .The maximum axis capability in CNC machines has revolutionized the manufacturing industry by offering enhanced precision, improved efficiency, and expanded machining possibilities. Industries such as aerospace, medical device manufacturing, automotive, and mold-making have greatly benefited from the capabilities of these machines.

Thanks for that info. My background is in cnc metal production, moldmaking and hi speed manufacturing and the machines are substantially different with table travel on x & y as opposed to the head gantry movement. .IKLESTAR 500W Spindle CNC Machine for Metal, 3 Axis Desktop CNC Router with Offline Controller, 430 x 390 x 90mm Working Area - Amazon.com. . a 500W spindle and NEMA17 stepper motor, the 4540 3-axis CNC router .5-Axis CNC Machines That Offer Maximum Flexibility. The SRTi series of 5-axis CNC machines offers multiple advantages, starting with the machine's design configuration that utilizes a swivel head and a C-axis rotary torque table that is embedded in the machine table and flush with the surface. The generous size the machine table provides . I then power ON the machine, home it and try to start the simulation but I get an error: "Program exceeds machine maximum on axis Z.". The G-code is written with Z=0 as the surface of the work. After homing your machine thinks that Z=0 is the top of travel. You need to use the "touch-off" button in the Axis GUI.

The geniSYS ™ IV is a highly portable 3 axis CNC milling machine. The motion control command center provides the ultimate in performance monitoring and technician safety. Applications Designed for the accurate removal of cracked pr broken studs up to 11" diameter and the precise refurbishment of damaged threads.

what is 5 axis machining

cnc mill axis diagram

The z axis in this case would show 7 for the graphical display, and would be in the RED. EDIT: For highlighting the code, the machine will try to do as you programmed it. As far as I know there is not a way to highlight the "faulty code". As far as the machine knows, if the syntax is correct: the code is correct and will try to execute.The Mazak INTEGREX 400IV is a CNC machine designed for multi-tasking capabilities that enhance productivity. This model is widely used in industries such as automotive, aerospace, and medical due to its ability to produce intricate parts. . Maximum Machining Length: 60: 1524: X-axis Travel: 24.8: 630: Y-axis Travel: 9.8: 250: Z-axis Travel .

Wenzel XOrbit CNC machine details, specifications, industries, and reviews. Rapid Results AI. Login / Signup. CNC Machines (1442) CNC Mill (798) Vertical Machining Center (646) CNC Lathe . Maximum Travel X-Axis: 30 inches: 762 mm: Maximum Travel Y-Axis: 40 inches: 1016 mm: Maximum Travel Z-Axis: 25 inches: 635 mm:

3 axis CNC machines: The simplest and cheapest type.Good for cutting flat 2D and 2.5D parts. 4 axis CNC machines: More flexible and accurate.Can drill on sides and cylindrical surfaces. 5 axis CNC machines: The most advanced and expensive type.Can produce complex 3D shapes and angled features.A 4-axis machine that cannot link the fourth axis is termed the 3+1 axis or fake 4-axis, and a 5-axis machine unable to link the fourth and fifth axis is called a 3+2 axis or fake 5-axis. During processing, a 3+1 CNC milling machine needs to rotate the fourth axis to a specific position and then fix it in place for part processing.Assuming the processing is uniform, and the speed of the tool tip in WCS achieves the preset feedrate, then the velocity of each joint of the five-axis machine tool can be estimated In Table 2, there are allowed maximum feedrate for every axis, and the feedrate, which meets the speed limit for all axes, is F MAF = F C = 20.24 mm / min.

Patented 5-axis CNC machine; M400 5-axis CNC control; Mastercam 5 axis CNC software with Port Expert. 6 days personalized CNC porting training; . Maximum table load: 2425lbs (1100kg) Spindle power: 36 Hp / 27 kW: Spindle taper: CAT 40 (BT40 optional) Spindle speed: 20,000 RPM: Rapid feed rates (X,Y,Z)5-Axis CNC Machining Center Offers Maximum Flexibility. The SRTi series of 5-axis CNC mills offers multiple advantages, starting with the machine's design configuration that utilizes a swivel head and a C-axis rotary torque table that is embedded in the machine table and flush with the surface. The generous size the machine table provides .While 3-axis CNC machines are versatile and cost-effective, they may fall short when producing parts with more complex geometries, where access to multiple faces of the part is needed in a single setup. 4-Axis CNC Machining. A 4-axis .

Four-axis CNC machines may cut along all four axes at the same time or along the x, y and z axes simultaneously and around the vertical axis separately. These two designs for four-axis machines could affect production .The Hurco VMX60SWi 5-Axis CNC mill offers maximum flexibility. The SW series of 5-axis CNC mills offers multiple advantages, starting with the machine's design configuration that utilizes a swivel head. Heavier digital servo drives, larger ball screws, and larger linear rails increase accuracy and deliver superb surface finish. .The Kent CKE6150Z stands as a significant name in the CNC machine sector, renowned for its efficient performance and adaptability. . Maximum Turning Diameter: 20: 508: Maximum Turning Length: 50: . Travel X-Axis: 12: 304.8: Travel Z-Axis: 40: 1016: Kent CKE6150Z Upgrades and Features. Advanced control systems for precise operations .

Get ACE 3-Axis 2 Axis Cnc Turning Machine Compact Turn, Maximum Turning Length: 450, Maximum Turning Diameter: 240 at best price in Ahmedabad, Gujarat by Hare Krishna Industries and more manufacturers | ID: 21163276362The right 5-axis CNC milling machines for every application. With a total of ten series, DMG MORI offers suitable 5-axis CNC machines for almost every application. While the CMX U series is the cost-effective entry point to 5-sided machining, the compact DMU models open the door to the simultaneous 5-axis milling of components weighing up to . SPECIFICATIONS five-CNC MILLING MACHINES The range of motion in the X axis-longitudinal mm2400 The range of motion in the axis Y - (traffic portal) mm 3400 The range of motion in the Z-axis-vertical mm 850 Distance between columns 2190 mm A axis (rotation of the spindle head) + / -115 C axis (rotation of the head) + / -240 Ability to work all .VL-1600ATC+C CNC Vertical Lathe Milling Machine with C Axis. Maximum cutting height: 1200mm . Maximum workpiece weight: 8000kg . No installation required. Simple operation. Support video teaching. 1 Year for machinery warranty . CNC control function: Fanuc 0i-T (10.4″ LCD), standard function 1: 17: Spindle motor 37/45KW 1: 18: C-axis .

Genmitsu CNC Router Machine PROVerXL 4030 V2, Fast Speed for Wood Metal Acrylic PCB MDF, Upgrade 3 Axis Engraving Machine with Closed-Loop Motor and Ball Screw, Working Area 400 x 300 x 110mm - Amazon.com . With a maximum travel speed of 5000 mm/min, the PROVerXL 4030 V2 can complete projects quickly and efficiently, saving time and .

The numbers of axes determine what type of movement a CNC machine can conduct. Axes Movements. X axis – left to right; Y axis – front to back; Z axis – up and down; A axis – 180° rotation around the X axis; B axis – 180° rotation around the Y axis; C axis - 180° rotation around the Z axis; Types of CNC Machines. 3 Axis – X, Y .500W CNC Router Machine, MYSWEETY 3020 PLUS CNC Wood Router 3 Axis Desktop CNC Machine for Metal Wood Acrylic MDF with Limit Switches, Emergency-Stop, Working Area 300*200*73 mm(11.81*7.87*2.87 inch) - Amazon.comFind your 4-axis machining center easily amongst the 195 products from the leading brands (FOM Industrie, Knuth Machine Tools, GROB, .) on DirectIndustry, the industry specialist for your professional purchases. . the 4 axis CNC machining center, . The models from 3 to 5 controlled axes allows milling and drilling PTP with maximum . In today's fast-paced manufacturing environment, efficiency and productivity have become the cornerstones of success. One of the key technologies that have revolutionized the manufacturing industry is 5-Axis CNC milling. This technology has enabled manufacturers to produce highly complex and intricate parts with unparalleled accuracy and precision. However, .

cnc machine axis identification

carnaud metal box crown

$14.26

maximum axis in cnc machine|cnc mill axis diagram