cnc machine layout Product teams that focus on DFM throughout the design phase can drastically reduce production times and costs associated with CNC machined parts. In this downloadable guide, we’ve compiled eight common DFM . Laser cutting has become extraordinarily productive—if the head doesn’t halt or crash, of course. Considering how productive the latest laser cutting technology is, smart nesting has become more important than ever for metal fabrication shops. o_shumilova / .

0 · machine shop tool room organization

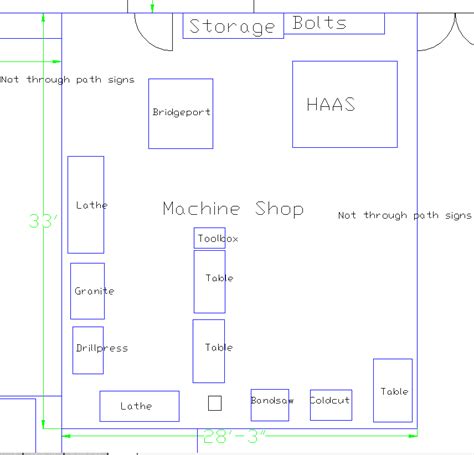

1 · machine shop floor plan layout

2 · cnc machine tool design

3 · cnc machine structure design

4 · cnc machine shop floor layout

5 · cnc machine parts diagram

6 · cnc machine part names

7 · cnc machine components list

In solar panel systems, the junction box serves as the heart of the wiring setup, managing connections between individual solar panels and the rest of the system. A junction box is a protective enclosure where wires converge and connect.

In less than 15 minutes, you will learn all you need to know to design parts optimized for CNC machining: from Design for Machinability rules to cost reduction tips and from material selection guidelines to surface finishing .In this comprehensive guide, we will delve into the key considerations and best practices for designing an efficient CNC machine shop floor layout that maximizes productivity and ensures . Making a design for CNC machining requires expertise. Here is everything you need to know about CNC machining design and guidelines.

Product teams that focus on DFM throughout the design phase can drastically reduce production times and costs associated with CNC machined parts. In this downloadable guide, we’ve compiled eight common DFM . The time it takes to implement a CNC machine shop layout that naturally flows through each stage of the production process will be more than made up by the time you save, reducing the amount of ground that materials . Get expert tips and recommendations to maximize efficiency and achieve optimal results with our CNC machining design guidelines.In less than 15 minutes, you will learn all you need to know to design parts optimized for CNC machining: from Design for Machinability rules to cost reduction tips and from material selection guidelines to surface finishing recommendations.

Whether you’re setting up a new machine shop or reorganizing your existing setup, a sound layout can make it easier for each CNC machinist to do their job efficiently. Learn more in this post from Premier Equipment.

machine shop tool room organization

In this comprehensive guide, we will delve into the key considerations and best practices for designing an efficient CNC machine shop floor layout that maximizes productivity and ensures a smooth manufacturing process. Making a design for CNC machining requires expertise. Here is everything you need to know about CNC machining design and guidelines. Product teams that focus on DFM throughout the design phase can drastically reduce production times and costs associated with CNC machined parts. In this downloadable guide, we’ve compiled eight common DFM considerations that should remain top-of-mind when designing parts for CNC machining. The time it takes to implement a CNC machine shop layout that naturally flows through each stage of the production process will be more than made up by the time you save, reducing the amount of ground that materials and personnel must cover.

A well-planned machine shop layout is important for the efficiency, safety, and growth of your CNC business. By considering space requirements, electrical and ventilation needs, safety, ergonomics, storage, noise reduction, and future expansion, you’re setting up your shop for success.

machine shop floor plan layout

Designing for CNC machining can be improved by simply following these rules and guidelines. Our design-for-manufacturability guide can also help you trim costs, shorten leadtimes, and improve your parts’ overall quality. This paper covers various aspects of CAD designs and significant considerations for designing features for CNC machining. By using 3D design models to visualize your CNC machine layout, you can make sure it all fits ahead of time, and get back to cutting chips quickly.

Get expert tips and recommendations to maximize efficiency and achieve optimal results with our CNC machining design guidelines.

In less than 15 minutes, you will learn all you need to know to design parts optimized for CNC machining: from Design for Machinability rules to cost reduction tips and from material selection guidelines to surface finishing recommendations. Whether you’re setting up a new machine shop or reorganizing your existing setup, a sound layout can make it easier for each CNC machinist to do their job efficiently. Learn more in this post from Premier Equipment.

In this comprehensive guide, we will delve into the key considerations and best practices for designing an efficient CNC machine shop floor layout that maximizes productivity and ensures a smooth manufacturing process. Making a design for CNC machining requires expertise. Here is everything you need to know about CNC machining design and guidelines. Product teams that focus on DFM throughout the design phase can drastically reduce production times and costs associated with CNC machined parts. In this downloadable guide, we’ve compiled eight common DFM considerations that should remain top-of-mind when designing parts for CNC machining.

stainless steel jewelry box hinges

The time it takes to implement a CNC machine shop layout that naturally flows through each stage of the production process will be more than made up by the time you save, reducing the amount of ground that materials and personnel must cover. A well-planned machine shop layout is important for the efficiency, safety, and growth of your CNC business. By considering space requirements, electrical and ventilation needs, safety, ergonomics, storage, noise reduction, and future expansion, you’re setting up your shop for success.

Designing for CNC machining can be improved by simply following these rules and guidelines. Our design-for-manufacturability guide can also help you trim costs, shorten leadtimes, and improve your parts’ overall quality. This paper covers various aspects of CAD designs and significant considerations for designing features for CNC machining.

stainless steel junction box ip66

cnc machine tool design

There are a few on the market, like Junction Box that comes with VPI JMW 9 tonearm. Besides the major negative feature - price (why pay for something I can assemble in my garage for free?), they usually made only for RCA or balanced XLR cables.

cnc machine layout|cnc machine structure design