types of hammers used in sheet metal work Common Uses: Tinner’s hammers are essential tools in sheet metal work, where they are used for forming, shaping, and joining metal components. The rounded face is suitable for striking and shaping metal, while . Steel ammo cases are typically made through a process called deep drawing, which involves forming a flat sheet of steel into a cylindrical shape. This manufacturing method ensures strength, durability, and precision for these essential components of ammunition.

0 · sheet metal shaping hammers

1 · sheet metal hammers types

2 · sheet metal hammer harbor freight

3 · sheet metal edge shapers

4 · sheet metal edge former

5 · planishing hammers for working metal

6 · metalworking hammer

7 · cp planishing hammer dies

All Points Fasteners gives you a sheet metal screw definition, along with its different types and how to use them. We provide enough guidance to eliminate the guesswork when you’re deciding between sheet metal screws and what type matches your applications.

In this post, we’ll explore the various types of hammers, categorizing them into general-purpose hammers, specialized hammers for specific tasks, metalworking hammers, soft-faced/non-marring hammers, .

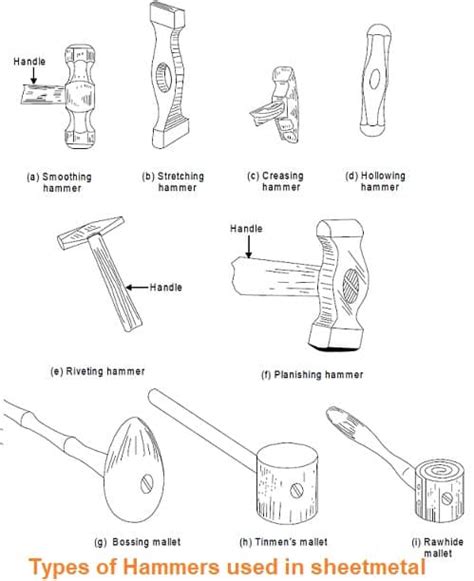

Common Uses: Tinner’s hammers are essential tools in sheet metal work, where they are used for forming, shaping, and joining metal components. The rounded face is suitable for striking and shaping metal, while .Fig shows the various types of hammers used in sheet metal work for forming shapes. The uses of different kind of hammers are given as under: (a) . A. Types of Metal-Work Hammers. 1. Raising Hammer. As the name suggest these hammers are used to shape sheet metals into a concave and cylindrical shape such as bowls, .

This post will deal in the different types and styles of sheet metal hammers, and the processes for which they can be used. Here are some of the most common processes that are commonly completed with the aid of the .Choosing a perfect type of hammer for metalsmithing or jewelry work is rarely as simple as picking up the one closest to you. Different types of hammers have different uses and each style is perfectly suited for its intended use. Download .A sheet metal hammer is a type of hammer designed specifically for use in sheet metal work. It is a specialized tool that has a distinctive shape and is used to shape and manipulate sheet .Choose from our selection of sheet metal forming hammers, riveting hammers, ball peen hammers, and more. In stock and ready to ship.

Best Practices. Maintain a steady hand and use the right tool for each material. Keep tools sharp to extend their lifespan and ensure precision. Always wear safety gear and keep . Claw Hammers: Widely known as the most popular hammer for general work, claw hammers are used for pounding another surface or extracting nails from the work piece. The hammers, which weigh anywhere from 7 to 32 oz., provide unsurpassed balance and temper while blowing. . Sheet Metal Deburring – Types and Methods Discussed. Top 10 Necessary . Hammer is a must in workshops. It also helps in household work. The classification of hammers can be done using several criteria’s. We will discuss about the types of hammers. Let’s discuss one by one. 3D Model of .

Each and every car body shop, industrial machine shop, and automobile repair shop should select sheet metal hammering for their own sheet metal fabrication and repair needs as well. Power hammers are mechanically powered forging instruments that use electricity to raise the hammer and strike. Metalworkers have used power hammers since the late .Corner notcher: These sheet metal cutting tools are used on different types of sheet metals. It is powered hydraulically. Planishing hammer: Planishing hammers are used as sheet metal tools to flatten, finely shape, straighten, and smoothen sheet surfaces.different types and weights of hammers and mallets, each with a very specific use. 1 / 176. 1 / 176. Flashcards; Learn; Test; Match; . commercial sheet metal and automotive body work. . sharped pointed punches used to transfer dimensions and locations onto sheet metal for drilling.The most common type of hammer used in automotive work, it has a flat face for general striking. It also has a round end for shaping metal parts, such as sheet metal or rivet heads. 1 / 6. 1 / 6. Flashcards; Learn; Test; Match; Q-Chat; Created by. cesar_trinidad4. Share. Share. Get better grades with Learn.

Know About Sheet Metal Fabrication and Types of Tools Used. Sheet metal fabrication primarily involves the use of sheet metals to build or fabricate metal structures, electronic goods, automotive parts, and more. . Some of these are manual, while others work on power. Sheet Metal Bending: A metal sheet is bent and stretched in particular .

They range in weight and size and while you might think the heavier the better, smaller ball peen hammers are better for shaping metal. Blocking hammer: A blocking hammer is like the finish hammer of metal work. It has a large flat surface for shaping sheet metal and leaving behind an unmarred surface. Explore various types of hammers and their uses. Find the perfect hammer for your project, enhance efficiency, & ensure safety with our guide. Skip to content. Call Us: +91-6239501818; li> Call Us: +91-9815579321; . This hammer is commonly used in blacksmithing, sheet metal work, and other metalworking applications where shaping and modifying .Apparently someone makes ball peen hammer with a magnifying glass in it which makes it a multi-tool not a new type of hammer IMO. . They forgot sheet metal hammer. Rock Hammer. M.C. Hammer. Reply reply swish301 . Surprised to not see a sheet metal hammer, for making duct work. It's so slick and cool looking.

sheet metal shaping hammers

What Are the Tools Used in Sheet Metal Work? You'll use band saws, plasma tables, drill presses, angle grinders, and bench grinders for shaping, cutting, and finishing sheet metal. Precision tools like press brakes and wire cutters ensure accuracy in your work. A rotary tool for grinding, sawing, honing, and polishing metal, used in various professions like welding and sheet metal work. Metal Nibbler: For cutting sheet metal with minimal distortion, ideal for cutting small channels or corrugated metal. Flux Core Welder: A semi-automatic or automatic arc welder, versatile and useful for general repairs .

2. Name the metals commonly used in sheet metal work. 3. Write short notes on: (a) Punching (b) Piercing (c) Blanking (d) Slitting (e) Bending (f) Lancing 4. Discuss the different sheering operations performed on sheet metal. 5. Explain the difference between punching, blanking and piercing. 6. Discuss the various types of hammers used in sheet .

These hammers are designed to be light and easy to maneuver. Other types of hammers include ball peen hammers, which are used for riveting and other types of metal work; cross peen hammers, which are used for shaping metal; and curved head hammers, which are used for paint removal. Dollies are also essential auto body tools. METALS USED IN SHEET METAL WORK The following metals are generally used in sheet metal work: 1. . food handling articles, tools and instruments for surgery work in hospitals and components of chemical plants .It's more useful in sheet metal work and repair. Other than it's intended purpose for peening pin heads. . then the 8 years I did as a Farrier I had one type of hammer. Shoe turning hammers or rounding hammers. You would be amazed at the work you can turn out with a simple shoe turning hammer and minimal tools. They tend to have a lovely big .

The most commonly used grade in sheet metal processing is austenitic stainless steel, particularly Type 304 (US designation) or 1.4301 (European designation). This grade is equivalent to the Japanese Industrial .A. Types of Metal-Work Hammers. 1. Raising Hammer. As the name suggest these hammers are used to shape sheet metals into a concave and cylindrical shape such as bowls, vases, and other hollow shapes by hammering against a wooden stake or metal stake. These have rectangular cross-section on both the sides of the head. In many cases only one hammer type may be applicable for the . How does an impact hammer work? . A vibratory hammer is a specialty hammer used to drive sheet piles in or out of the ground. Impact hammers use a large weight to strike the pile. Vibratory hammers are relatively quiet and have many advantages, such as fast installation.

A36 sheet metal; A572-50 sheet metal; A516-70 sheet metal; AR400 sheet metal; A588 sheet metal; A1011 sheet metal; Tool Steel. Immensely versatile, tool steel is a rigid alloy containing about one percent carbon. As with alloy steel, the elements contained within tool steel vary in type and ratio depending on the desired application. A body hammer is a type of striking tool used to shape metal panels. Most often, they’re used in body shops and custom metalworking shops to fix and shape fenders, gas tanks, and other metal . However, the most common type of hammer found from the Late Bronze Age in Britain is rarely seen outside of specialist blacksmith workshops where it is used for sheet metal work. This type of hammer has a facetted face and was in use until the turn of the last century when sawblades and other sheet metal objects were still made by hand (See .The hand saw that is used primarily for cutting metal is the. Don't know? Terms in this set (25) . Which of the following type of wrench is most prone to slipping? open-end wrench. Which of the following tools is most likely to be used correctly for the final tightening of a bolt? Box-end wrench. The universal joint is typically part of a.

A sheet metal hammer is a type of hammer designed specifically for use in sheet metal work. It is a specialized tool that has a distinctive shape and is used to shape and manipulate sheet metal without causing damage to the surface. Sheet metal hammers come in a variety of sizes and shapes, each designed for specific tasks and preferences.

sheet metal hammers types

steel box spring full

Sheet metal tools are among the most commonly used tools in an aircraft technician’s tool chest. . In making these tools, close attention is paid to the type of materials used in the assembly .

A sheet metal setting hammer is a tool used by metalworking professionals to shape and form sheet metals. It consists of a long, flat face on one end and a round, ball-shaped end on the other. . Other hammer types used in metal work include claw hammers, rawhide mallets, machinist hammers and sledgehammers.Hammers The hammers, in sheetmetal work, are used for forming shapes by hollowing, raising stretching or throwing off processes. They are many types of hammers, but the most commonly used hammers, in sheet-metal work are follows: (a) Ball peen hammer : The ball peen hammer has a round, slightly curved face and a round head. It is general .

steel boxs

sheet metal hammer harbor freight

Musical movements come in various sizes, affecting the sound and structure of the box. These mechanisms look similar to a fine-tooth comb, with flat metal pins placed side-by-side like piano keys. By design, either a rotating cylinder or disc strikes the teeth of the comb to produce the music notes and automatically play specific tunes.

types of hammers used in sheet metal work|sheet metal edge former