cnc lathe machining turning free sample A full CNC programming example with ID/OD (Turning/Boring operations) for cnc machinists who work on a cnc lathe machine. A must to learn/practice for those who are learning cnc programming.. Regular 4" 1900 box with a Caddy H6 or H23. A bit too provocative for the average person. If your box is wobbling, it's because you don't have far-side support. If you are cutting up studs for far-side support, you .

0 · simple cnc lathe program

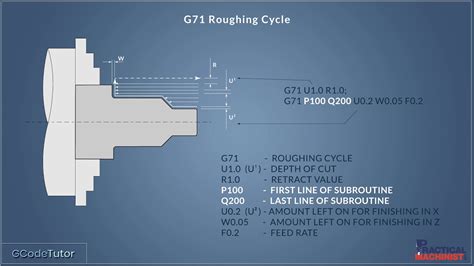

1 · helman fanuc lathe programming

2 · g71 lathe programming examples

3 · fanuc lathe programming examples

4 · cnc programming examples

5 · cnc lathe programming exercises

6 · cnc lathe programming

7 · cnc lathe program example

Installing a junction box in an attic is a great way to access multiple electrical circuits in a single, safe location. A junction box is a metal or plastic box that houses electrical connections and provides a safety barrier between the wiring and the user.

simple cnc lathe program

electrical box 2 fitting

helman fanuc lathe programming

A full CNC programming example with ID/OD (Turning/Boring operations) for cnc machinists who work on a cnc lathe machine. A must to learn/practice for .CNC lathe program examples for beginner level cnc programmers / cnc machinists. CNC G-code program examples, no cnc canned cycle is used, cnc program example from step turning to .A full CNC programming example with ID/OD (Turning/Boring operations) for cnc machinists who work on a cnc lathe machine. A must to learn/practice for those who are learning cnc programming..

CNC lathe program examples for beginner level cnc programmers / cnc machinists. CNC G-code program examples, no cnc canned cycle is used, cnc program example from step turning to simple arc programming.Simple cnc lathe program example to show how a cnc lathe program can be made to turn a simple contour with Radius in it. Multiple diameters are cut and both Clockwise and Counter Clockwise Radius are machined. It’s full of examples on a case-by-case basis for all the common g code commands used by your machine tool. Want completed programs? No worries, here’s a bunch of example gcode files you can try on your cnc machine to gain a better understanding of g-codes.

CNC Lathe Programming for Turning. CNCCookbook’s G-Code Tutorial: Learning g code the easy way. CNC Lathe Axes; Diameter Versus Radius Mode; Basic G01 and G02/03 Moves: Lines and Arcs Part Zero on CNC Turning Programs; Tool Changes and Tool Selection on the CNC Lathe; Automatic Chamfer and Corner Rounding with G01. See Also. Speed and . These are the different CNC programming examples we have both turning and milling.

electrical box adapter for ceiling fan

To machine any of the parts of these example, use the feedrates and speeds recommended by the tool manufacturer. The tool number will also be different depending on the machine. Programming with this type of coordinates implies the use of a "part zero" as a coordinate origin.To operate and program a CNC machine, a basic understanding of machining practices and math are necessary. It is also important to be familiar with the machine control and the placement of theComplete CNC program example for CNC machinists / programmers who work on CNC lathe machines with NCT cnc controls. In this program example G71 Turning Cycle is used for stock. Click here for a Handy g-code and m-code programming reference list for CNC Lathes and Turning Centers with examples

A full CNC programming example with ID/OD (Turning/Boring operations) for cnc machinists who work on a cnc lathe machine. A must to learn/practice for those who are learning cnc programming..CNC lathe program examples for beginner level cnc programmers / cnc machinists. CNC G-code program examples, no cnc canned cycle is used, cnc program example from step turning to simple arc programming.Simple cnc lathe program example to show how a cnc lathe program can be made to turn a simple contour with Radius in it. Multiple diameters are cut and both Clockwise and Counter Clockwise Radius are machined.

It’s full of examples on a case-by-case basis for all the common g code commands used by your machine tool. Want completed programs? No worries, here’s a bunch of example gcode files you can try on your cnc machine to gain a better understanding of g-codes.

CNC Lathe Programming for Turning. CNCCookbook’s G-Code Tutorial: Learning g code the easy way. CNC Lathe Axes; Diameter Versus Radius Mode; Basic G01 and G02/03 Moves: Lines and Arcs Part Zero on CNC Turning Programs; Tool Changes and Tool Selection on the CNC Lathe; Automatic Chamfer and Corner Rounding with G01. See Also. Speed and .

These are the different CNC programming examples we have both turning and milling.

To machine any of the parts of these example, use the feedrates and speeds recommended by the tool manufacturer. The tool number will also be different depending on the machine. Programming with this type of coordinates implies the use of a "part zero" as a coordinate origin.

To operate and program a CNC machine, a basic understanding of machining practices and math are necessary. It is also important to be familiar with the machine control and the placement of theComplete CNC program example for CNC machinists / programmers who work on CNC lathe machines with NCT cnc controls. In this program example G71 Turning Cycle is used for stock.

A junction box is an essential part of the electrical wiring systems for homes and commercial buildings. These metal or plastic boxes house and safely protect a structure's electrical connections. The electrical casings come in .

cnc lathe machining turning free sample|simple cnc lathe program